Information briefs for the week check out CES2024 with its fewer robots however rather more AI (synthetic intelligence), Doosan Robotics at CES getting an early entry into the AI-infused cobot marketplace for 2024, cobots for 2024 pursuing the “closing answer” within the hunt for good palletizing in a projected $2.2 billion international market, ABB Robotics chopping in two new instructions with its robots (logistics and residential constructing), and a small North Carolina entrepreneur stick-building full houses with manufacturing unit robots.

CES2024: Few cobots, a number of AI

Surprisingly, the Wall Avenue Journal despatched zero reporters to CES2024, with one WSJ journalist remarking that CES has actually develop into a super-size auto present with tons of devices; and “its affect in tech has been waning.” Appears a legitimate statement. Throw in a number of showrooms with slick autonomous farm robots and large idea drones for future city journey, and also you’ve acquired CES2024 in a nutshell.

One factor that just about each one of many 4,000-plus exhibitor cubicles had in frequent was some form of synthetic intelligence (AI) married to their merchandise. With CES struggling since COVID to return to these heady days of wall-to-wall humanity (circa 2018), AI served effectively as a spark of curiosity to drive attendance, which a number of sources tabbed as within the 100K vary (report 180k in 2018).

One factor that just about each one of many 4,000-plus exhibitor cubicles had in frequent was some form of synthetic intelligence (AI) married to their merchandise. With CES struggling since COVID to return to these heady days of wall-to-wall humanity (circa 2018), AI served effectively as a spark of curiosity to drive attendance, which a number of sources tabbed as within the 100K vary (report 180k in 2018).

Simply to ensure that AI acquired sufficient consideration as this 12 months’s headliner, CES 2024 featured greater than 30 panel discussions on AI, GenAI, machine studying (ML), and their impression on varied enterprise segments.

One AI facet for positive was that CES2024, held January 9-12, in Las Vegas, was the 12 months’s kickoff and vanguard of many tradeshows to return that can be stockpiled to the rafters with AI-enabled industrial robots, cobots, and automation gear. As for CES2024, there was little in the best way of business something, aside from cobot maker, Korea’s Doosan Robotics, that was there in drive.

Since its wildly profitable IPO final October, Doosan has been ramping up public publicity and its PR agenda to the max. Getting a first-encounter soar on the AI-enabled cobot scene, Doosan rolled into CES2024 with a full-blown, new-product showcase in its 8,000-square-foot sales space (common house within the U.S. is 2,300 sq. toes). Doosan additionally made room for AI-controlled tractors from its Bobcat subsidiary.

Doosan took benefit of CES2024 to debut what it calls Dart-Suite, a cobot ecosystem that the corporate claims is “redefining the robotic expertise.”

Doosan’s new line of AI-enabled cobots are designed to tackle the extra labor-intensive duties throughout industries together with manufacturing, logistics, meals and beverage, structure, filmmaking, service sectors, and medical environments.

For one, Doosan unveiled its Otto Matic, a depalletizing and palletizing answer designed to deal with unstructured and random-sized packing containers, which was developed in partnership with pc imaginative and prescient expertise supplier Korea-based AiV and San Jose-based TDK Qeexo.

Going ahead, 2024 is shaping as much as be possibly the ultimate assault on depalletizing and palletizing options; Doosan and others are already claiming victory.

Cobots: In sizzling pursuit of pallets

Ever because it was patented in 1925 and popularized within the Thirties, how greatest and the way shortly to load and unload pallets has been pursued by staff and machines with out a lot enchancment, till the daybreak of the robotic, and now, its little brother, the cobot.

Palletizing and depalletizing with a robotic is finished nearly in isolation from folks. If not, accidents to staff in shut proximity to the robotic and pallet can simply happen. Robots fulfill the velocity a part of the equation however nonetheless will not be the perfect.

Cobots, now with larger payload capacities (between 20kg and 50kg) and longer reaches, are the instruments of alternative when palletizing alongside staff or with mixed-load pallets. Palletizing units are important for growing productiveness, lowering handbook labor, and optimizing materials dealing with procedures.

Cobots, now with larger payload capacities (between 20kg and 50kg) and longer reaches, are the instruments of alternative when palletizing alongside staff or with mixed-load pallets. Palletizing units are important for growing productiveness, lowering handbook labor, and optimizing materials dealing with procedures.

Cobot cells appear to be the very best setup for employee proximity and productiveness, however mixed-load pallets are nonetheless an elusive problem that just about a dozen cobot distributors appear to be hotly pursuing, with diverse ranges of success.

It is the problem that Doosan and its Otto Matic cobot declare to have conquered. Including a 3D imaginative and prescient system, Dart Suite software program, and machine studying (ML) appears to have performed the trick. Along with palletizing algorithms, Otto Matic will get educated on photos of each product form and measurement that it’ll ever encounter on the job, subsequently, says Doosan, their tech permits the system to acknowledge and classify blended and new object varieties, making it a extra versatile system. Otto Matic, subsequently, has no problem in loading or unloading mixed-load pallets.

With using refined sensors, and programming, cobot cells can prepare merchandise on pallets in a methodical method, streamlining logistical processes and enabling the sleek move of products by warehouses, factories, and distribution facilities.

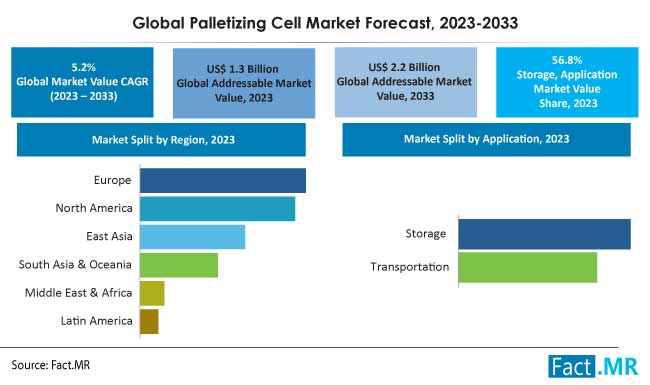

PALLETIZING MACHINE MARKET measurement was valued at $1.3 billion in 2023 and is predicted to succeed in $2.2 billion by the top of 2030 with a CAGR of 4.4% through the Forecast Interval 2024-2030.

ABB Robotics future-readies itself…twice!

Because the days of former CEO Ulrich Spiesshofer (2013-2019), Swiss-Swedish ABB has made it a degree of being future-ready in all facets of robotics in addition to that expertise’s future instructions. Twice just lately, ABB has demonstrated its chops at being future-ready.

FIRST: ABB’s cell robotics trifecta is an ideal instance. ABB, seeing the fast-approaching way forward for cell logistics, e-commerce, and AMRs, acquired (2018) Belgian robotics automation supplier, Intrion, to achieve “area experience in fast-growing logistics automation market.” Then, in 2021, purchased Spanish-based ASTI cell robotic maker, one of many EU’s best-known AMR builders. And now (5 days in the past), acquired Swiss startup Sevensense for its “eyes and brains” experience in AMR navigation.

FIRST: ABB’s cell robotics trifecta is an ideal instance. ABB, seeing the fast-approaching way forward for cell logistics, e-commerce, and AMRs, acquired (2018) Belgian robotics automation supplier, Intrion, to achieve “area experience in fast-growing logistics automation market.” Then, in 2021, purchased Spanish-based ASTI cell robotic maker, one of many EU’s best-known AMR builders. And now (5 days in the past), acquired Swiss startup Sevensense for its “eyes and brains” experience in AMR navigation.

So what do you assume now dominates ABB’s web site? How a few hero-image video clip of ABB’s AMRs (courtesy of ASTI) sporting eyes and sensors (courtesy of Sevensense) cruising by a warehouse? It seems like ABB has been a logistics chief since ceaselessly!

SECONDLY: ABB and Porsche Consulting will tackle constructing houses in a manufacturing unit. One other first for ABB! In line with Enterprise Insider (14 January 2024): “modular housing…is affected by firms which have gone bust.” But, the necessity for single-family housing each within the U.S. and EU (particularly Germany) is important (see video).

“Eberhard Weiblen, Chairman of the Government Board at Porsche Consulting, confused the importance of addressing the challenges the development business faces. He emphasised the potential for extremely automated factories to supply superior, cost-effective housing. By merging ABB’s cutting-edge robotic options with Porsche Consulting’s experience in state-of-the-art manufacturing unit planning and administration, the aim is to revamp the development business.”

Within the close to future, there could very effectively be households receiving packages shipped through ABB logistics to houses constructed by ABB’s robots.

Houses stick-built in a manufacturing unit

Even small entrepreneurs can construct houses in a manufacturing unit utilizing robots. Meet North Carolina-based BotBuilt.

Even small entrepreneurs can construct houses in a manufacturing unit utilizing robots. Meet North Carolina-based BotBuilt.

BotBuilt is the brainchild of Brent Wadas, Colin Devine and robotics engineer Barrett Ames. BotBuilt goals to create a robotic system that may “soak up a constructing plan, translate that plan right into a collection of machine instructions and ship these instructions to its system.

”The corporate doesn’t construct houses in its manufacturing unit from scratch, somewhat it focuses on simply setting up the framing. BotBuilt’s robots piece collectively panels for partitions, flooring trusses and roof trusses, that are the most important framing elements of houses (see video).

Ames says that his system prices about $1 per hour to run, and “may be reprogrammed to construct “totally” totally different body designs for houses comparatively shortly.” And affordably!