ISO 8573-1 is a world commonplace for measuring the standard of compressed air. It is essential for robotic palletizing as a result of the vacuum grippers usually utilized in these methods are pneumatic.

If you find yourself utilizing vacuum grippers for palletizing, the standard of the air can imply the distinction between efficiently choosing a field and dropping it.

However what’s the impression of air high quality in your work setting on the robotic?

How will you evaluate fashions of vacuum grippers and their air high quality rankings?

And the way do you inform what vacuum gripper can be greatest in your particular palletizing process?

Let’s take a look on the ISO 8563-1 commonplace to grasp how you should utilize it to make higher selections about your palletizing robotic.

What’s ISO 8573-1?

ISO8573-1 is a world commonplace for compressed air purity courses developed by the Worldwide Group for Standardization (ISO). It defines a set of standards for assessing and classifying purity of compressed air and is important for duties the place clear air is required.

The usual includes 8 components that present courses and check procedures. It classifies air high quality by the sort and measurement of contaminant or particles within the compressed air.

Sections of the usual are:

-

Purity courses for particles, water, and oil.

-

Check strategies for oil aerosol, humidity, stable particle, and oil/solvent.

-

Check strategies for stable particle content material and microbiological contaminants.

-

Strong particle check strategies.

-

Liquid water testing procedures.

From these checks and procedures, an air provide is given a score that signifies the purity of the air.

For robotic vacuum grippers, the kind of contaminant could fluctuate relying on the particular setting that you’re utilizing the robotic in. Nonetheless, the most typical sort is particles, such because the ambient mud in a warehouse setting.

Why air high quality is essential for dependable robotic palletizing

Air high quality is a property that folks usually neglect to contemplate when they’re buying a palletizing robotic. Nonetheless, the air high quality score of a robotic vacuum gripper can considerably have an effect on the robotic’s efficiency in a palletizing process.

Contaminants have an effect on the suction pressure of a vacuum gripper. Consequently, the air high quality influences the load of things that the gripper can elevate.

Most vacuum grippers have some form of air filtration system. Nonetheless, these have completely different rankings in accordance with ISO 8573-1. In case your gripper’s filtration system cannot filter the kind of contaminants current within the air, it might fail to choose up bins reliably.

In case your robotic is working in a clear room, you most likely haven’t got to fret about air high quality. For all different environments, it is best to contemplate the standard of the air.

How vacuum grippers use air when palletizing

The vacuum grippers usually utilized in palletizing robots work by making a vacuum pressure, usually with a vacuum pump linked to the gripper.

Vacuum grippers work through the use of the venturi impact, a precept that depends on the suction created when a fluid is pressured via a slim pathway. When compressed air is pushed via a venturi tube, it creates a vacuum with decrease stress than the environment.

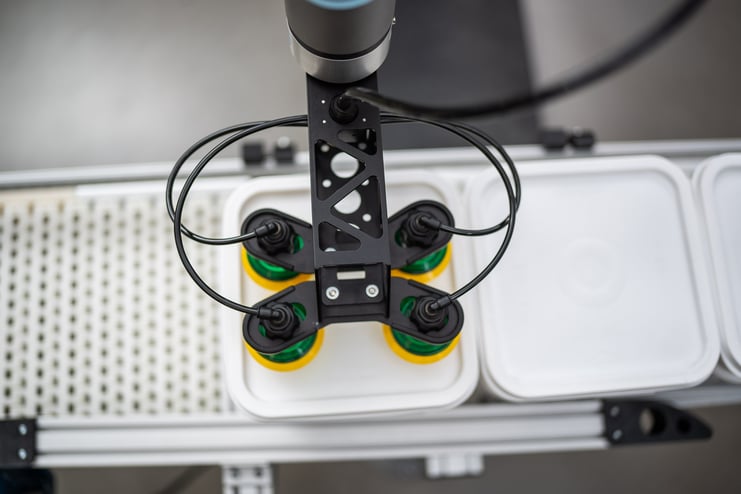

Vacuum grippers usually have two important operational components: suction cups and an air provide (which features a stress regulator with an air filtration system).

Throughout operation, the suction cups begin full of air. This air is then rapidly sucked out, making a destructive air stress within the cup which sticks the cup to the floor of the field.

If there are contaminants within the air provide, it creates a weaker lifting pressure by degrading the standard of the vacuum.

Evaluating the air score of two dependable vacuum grippers

You’ll be able to see the impression of air score on the efficiency of vacuum grippers by completely different fashions.

At Robotiq, we’ve three vacuum gripper ranges: EPick, AirPick, and PowerPick. The EPick consists of its personal mini vacuum pump inside the gripper itself – as an alternative of utilizing an exterior air provide – so it is barely completely different from the opposite two.

Let’s evaluate the AirPick and PowerPick to see the impression of air high quality score:

Instance 1: AirPick

AirPick is the proper alternative for an enormous variety of palletizing duties. It’s able to exactly lifting bins and objects for a lot of decide and place duties. It has a compact design for cobots and, in the proper environments, presents highly effective vacuum move.

The AirPick’s filtration system is rated at ISO 8573-1 Class 2-4-2. This implies it gives a particle measurement separation of <0.1µm — which is equal to the grain measurement of corn starch.

The air filter is 5 microns, the mist separator is 0.3 micron, and the micro mis separator is 0.01 micron.

Instance 2: PowerPick

PowerPick is a extra highly effective vacuum gripper that’s designed to extend the reliability and pressure for lifting heavier objects. It additionally presents many extra configuration choices to swimsuit much more palletizing duties.

The PowerPick’s filtration system is rated at ISO 8573-1 Class 7-4-4. This implies it gives a particle measurement separation of <40µm — which is equal to grains of plant pollen. The air filter can be 5 microns.

This score implies that the PowerPick can deal with air with particle sizes 400 instances bigger than the AirPick.

The improved vacuum system has a most load capability of 11.5 kg (25 lbs) and gives a powerful suction pressure to make sure bins are firmly held even in additional dusty environments.

What air high quality does your palletizing process want?

How will you use this info to resolve which palletizing system is best for you?

If you find yourself a vacuum gripper system, establish if the air high quality score of the vacuum matches that of the setting through which it will likely be working.

You’ll be able to both analyze the air high quality of your setting utilizing measurement tools. Or you possibly can run a check software with a vacuum gripper and establish that the efficiency meets your wants.

By understanding what class of air purity is critical in your specific software, you possibly can be certain that your palletizing process is operating at peak efficiency.

What questions do you could have about air high quality rankings? Inform us within the feedback beneath or be a part of the dialogue on LinkedIn, Twitter, Fb, or the DoF skilled robotics neighborhood.