Dec 22, 2023

(Nanowerk Highlight) Comfortable, skinny, and biocompatible stretchable conductive nanocomposites are essential in creating wearable skin-like units, good gentle robots and implantable bioelectronics. Though a number of design methods involving floor engineering have been reported to beat the mechanical mismatch between the brittle electrodes and stretchable polymers, it’s nonetheless difficult to comprehend monolithic integration of varied parts with various functionalities utilizing the present ultrathin stretchable conductive nanocomposites. That is attributed to the dearth of appropriate conductive nanomaterial techniques appropriate with facile patterning methods.

Laser-induced graphene (LIG), usually derived from laser irradiation of polyimide (PI), has numerous distinct deserves, comparable to facile digital patterning processes, compatibility with sample switch approaches, in addition to tunable bodily and chemical options to provide various wearable sensors.

Nonetheless, these multifunctional units are constructed on versatile PI substrates or comparatively thick elastic movies owing to the mechanical limitations in transferring LIG to gentle elastomers. As well as, the mechanical mismatch between the brittle LIG and elastic polymer hinders the stretchability of conductive nanocomposites.

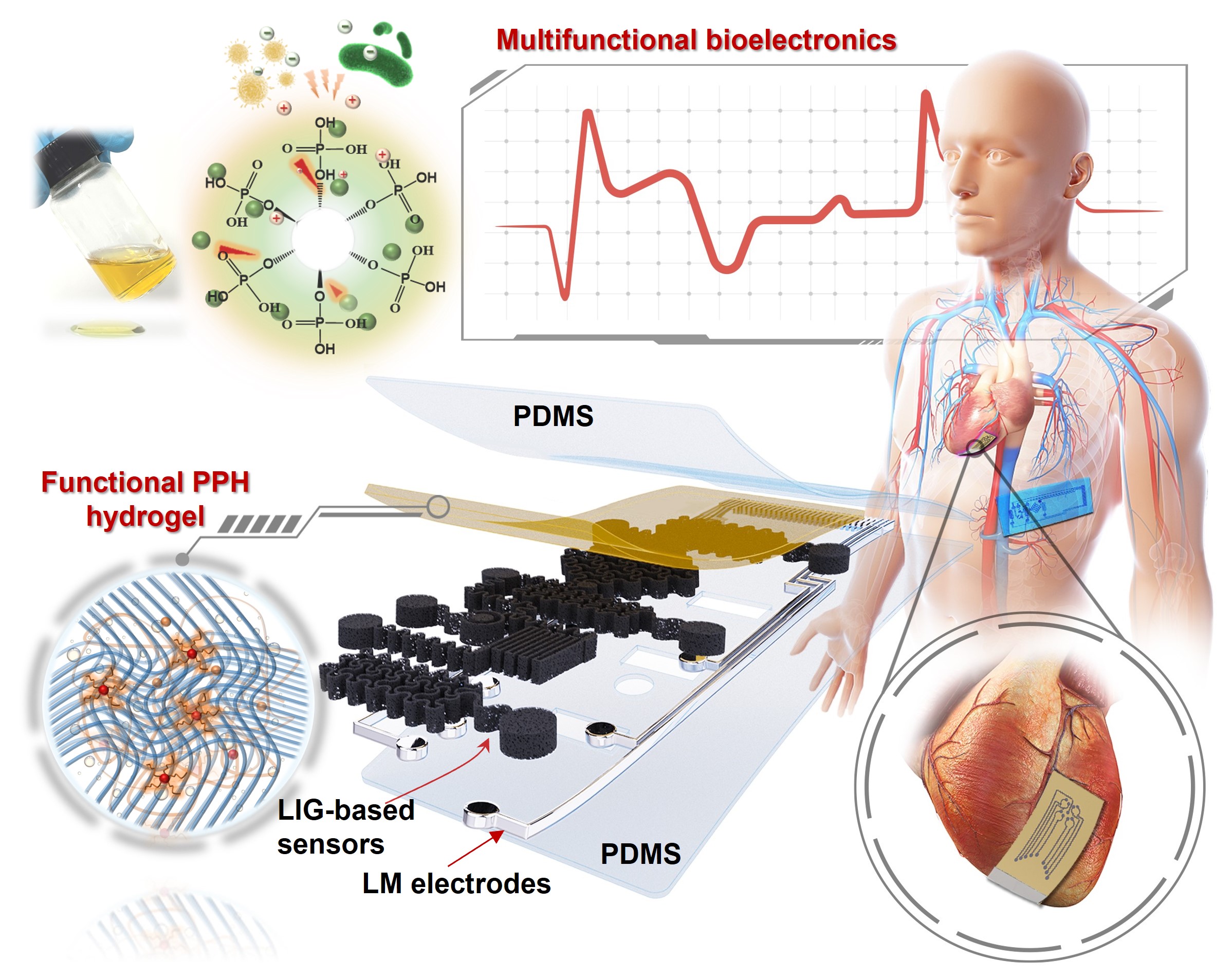

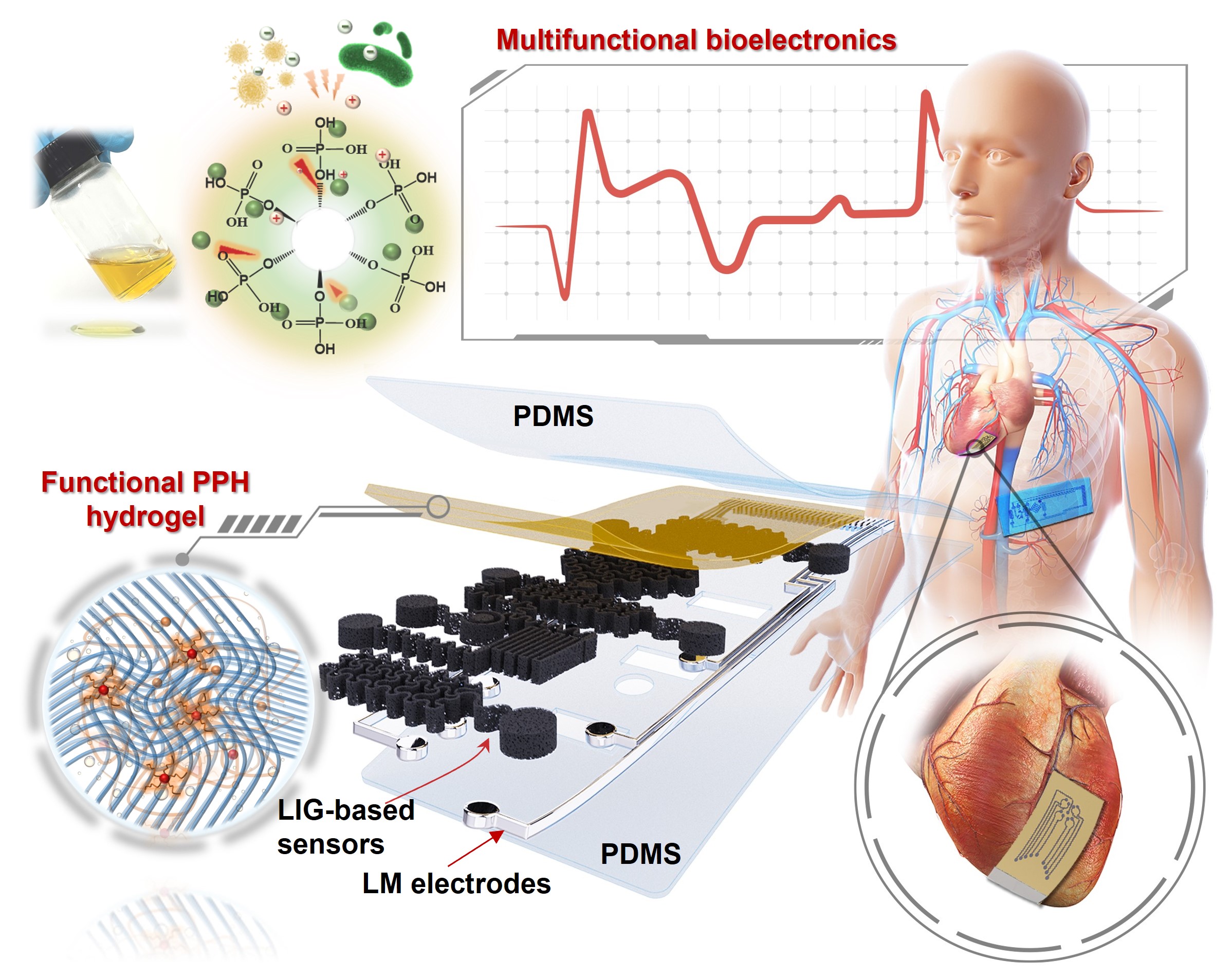

In a current research printed in Nature Electronics (“Stretchable graphene–hydrogel interfaces for wearable and implantable bioelectronics”), researchers from Zhejiang College report an ultrathin elastic LIG-hydrogel-based nanocomposite for multifunctional on-skin and implantable bioelectronics.

First, the authors suggest a brand new technique to create ultrathin patterned LIG-based nanocomposite, which is shaped by cryogenically (77 Ok) transferring LIG to a hydrogel movie (minimal thickness of 1.0 µm). Second, they tackle the mechanical mismatch between the brittle LIG and elastic polymer, which employs the hydrogel as an power dissipation interface and out-of-plane electrical path. Repeatedly deflected cracks will be induced within the LIG resulting in an over fivefold enhancement in intrinsic stretchability.

Total, this work supplies a viable technique to assemble ultrathin carbon-hydrogel-based stretchable nanocomposites for built-in sensor techniques, enabling various purposes in wearable/implantable bioelectronics and human-machine interactions (Determine 1).

Determine 1: Design of ultrathin, antibacterial and biocompatible PPH hydrogel-enhanced stretchable nanocomposites for wearable and implantable bioelectronics. (Picture courtesy of the researchers)

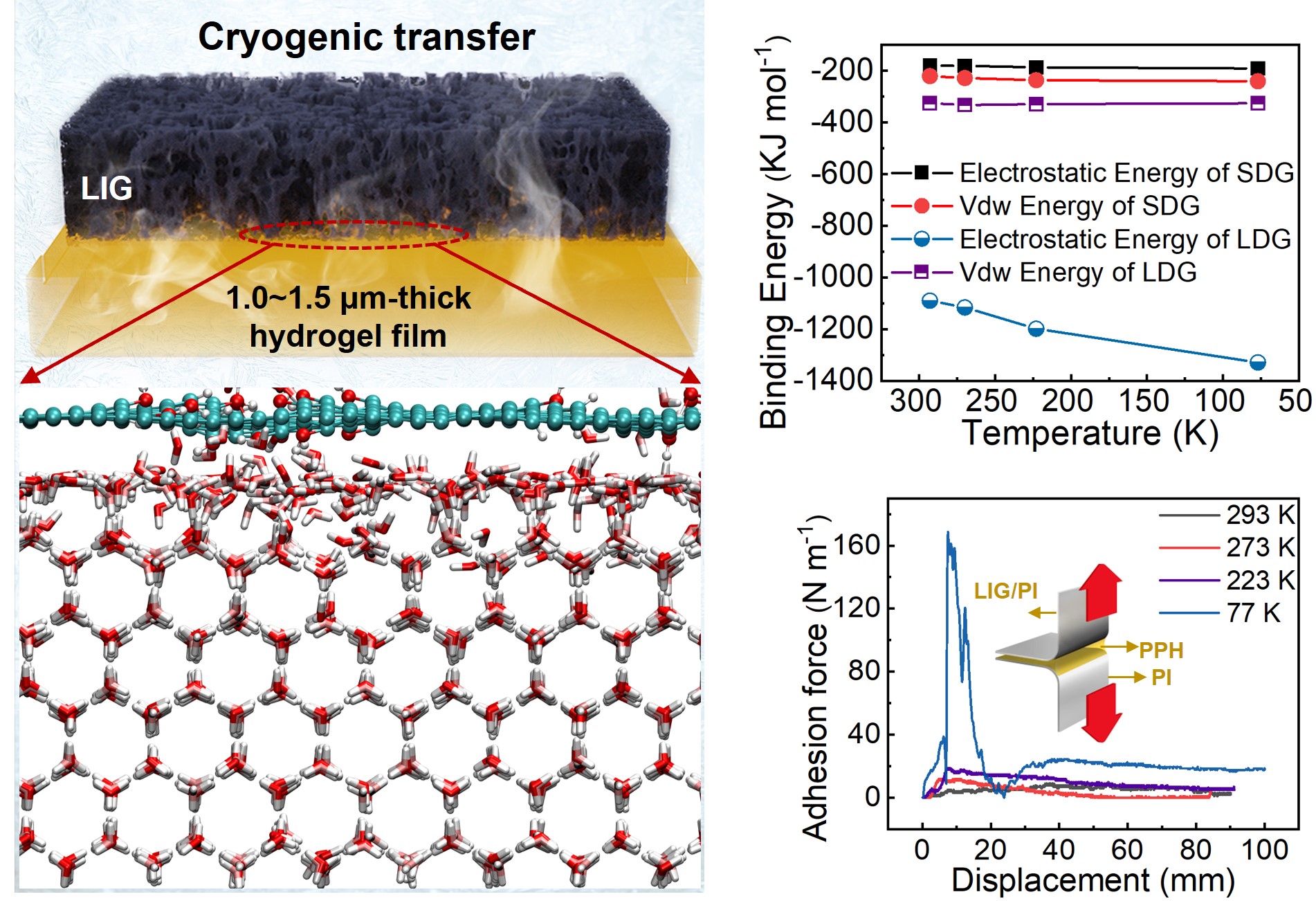

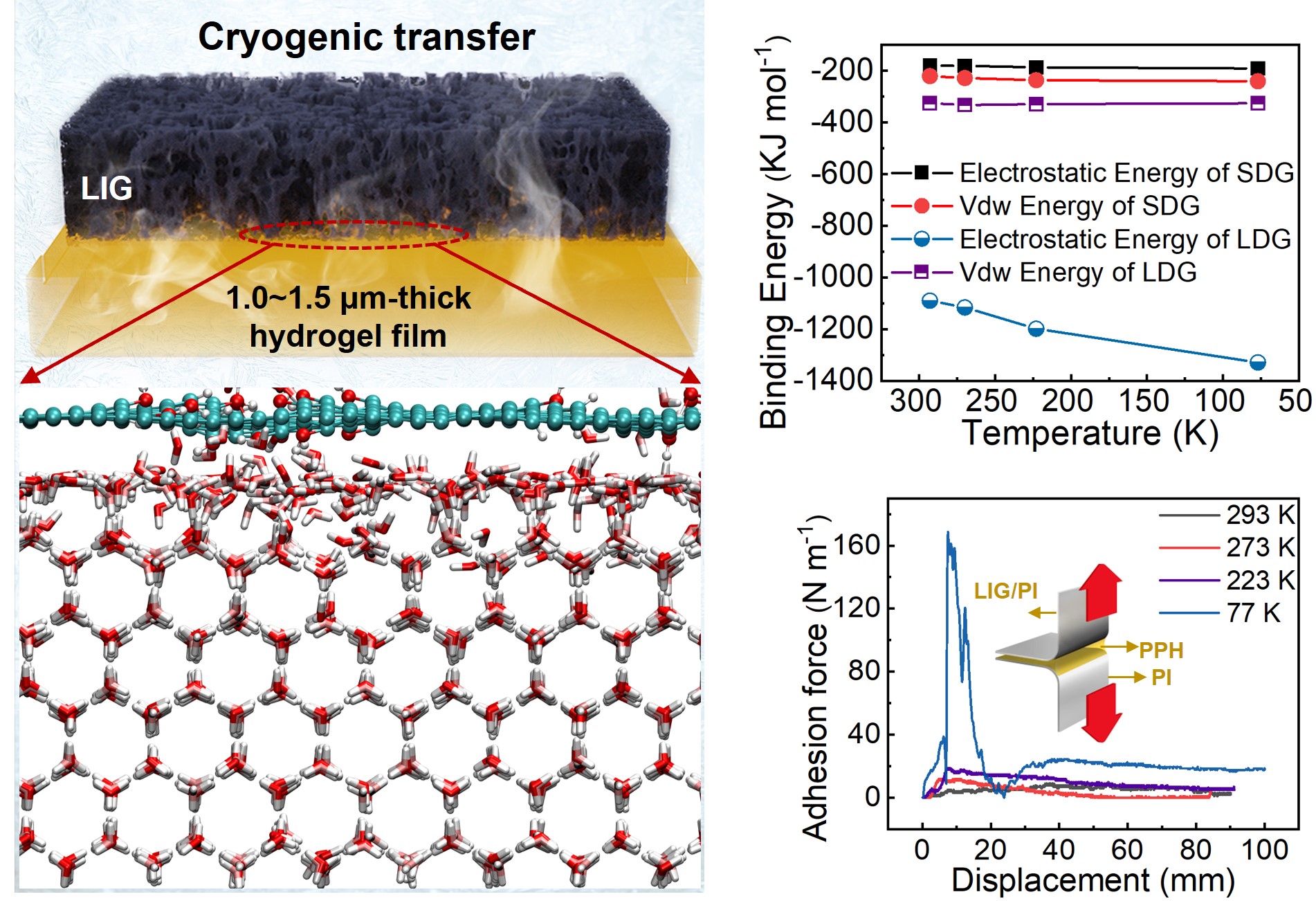

“Standard LIG switch methodology requires the a lot bigger thickness (>45 µm) of elastomers or adhesive tapes to supply a powerful interfacial drive through the peeling-off course of, hindering the conformal bioelectronics purposes,” says Prof. Kaichen Xu, corresponding writer of this publication. “The mechanical restrictions in transferring LIG to elastomers are overcome by a cryogenic switch method at -196 °C utilizing an ultrathin and adhesive polyvinyl alcohol/phytic acid/honey (PPH) hydrogel”.

Throughout the quick cooling course of, the interfacial binding power between faulty porous graphene and the crystallized water inside hydrogel is enhanced, as illustrated by molecular dynamics (MD) calculations. Such a dramatical enhance in superficial binding drive at 77 Ok was additionally captured within the 180° peeling check. The utmost transient peeling drive of 160 N m-1 at 77 Ok was noticed, which was a lot larger than that (<10 N m-1) originated from the autologous adhesion of PPH on the ambient temperature (Determine 2).

Determine 1: Design of ultrathin, antibacterial and biocompatible PPH hydrogel-enhanced stretchable nanocomposites for wearable and implantable bioelectronics. (Picture courtesy of the researchers)

“Standard LIG switch methodology requires the a lot bigger thickness (>45 µm) of elastomers or adhesive tapes to supply a powerful interfacial drive through the peeling-off course of, hindering the conformal bioelectronics purposes,” says Prof. Kaichen Xu, corresponding writer of this publication. “The mechanical restrictions in transferring LIG to elastomers are overcome by a cryogenic switch method at -196 °C utilizing an ultrathin and adhesive polyvinyl alcohol/phytic acid/honey (PPH) hydrogel”.

Throughout the quick cooling course of, the interfacial binding power between faulty porous graphene and the crystallized water inside hydrogel is enhanced, as illustrated by molecular dynamics (MD) calculations. Such a dramatical enhance in superficial binding drive at 77 Ok was additionally captured within the 180° peeling check. The utmost transient peeling drive of 160 N m-1 at 77 Ok was noticed, which was a lot larger than that (<10 N m-1) originated from the autologous adhesion of PPH on the ambient temperature (Determine 2).

Determine 2: Schematic of LIG switch on ultrathin PPH movies (thickness of 1.0~1.5 μm) by way of a cryogenic switch method (left graph). The superficial binding power was calculated primarily based on MD simulations. Calculated binding power of electrostatic interplay and Van der Waals interplay between the SDG, LDG and waters through the cooling course of (prime proper). The adhesion drive of PPH/PI and LIG/PI at totally different temperatures (293 Ok, 270 Ok, 223 Ok, 77 Ok) carried out by 180° peeling checks (backside proper). (Picture courtesy of the researchers)

Moreover, the proposed cryogenic switch technique allowed the switch of LIG onto different sorts of adhesive or non-adhesive hydrogels, indicating the universality of this switch expertise. However, solely the adhesive hydrogel shaped a mechanically steady binding interface particularly beneath the tensile pressure.

By means of the facile laser direct writing and cryogenic switch approach, multimodal sensor parts are built-in as a multifunctional wearable sensor sheet for on-skin in vitro monitoring. Moreover, the ultrathin and biocompatible traits of the micropatterned LIG-based nanocomposites permit to type the seamless contact with the guts of Sprague Dawley (SD) rats to in situ monitor cardiac alerts.

Offered by Zhejiang College as a Nanowerk unique

Determine 2: Schematic of LIG switch on ultrathin PPH movies (thickness of 1.0~1.5 μm) by way of a cryogenic switch method (left graph). The superficial binding power was calculated primarily based on MD simulations. Calculated binding power of electrostatic interplay and Van der Waals interplay between the SDG, LDG and waters through the cooling course of (prime proper). The adhesion drive of PPH/PI and LIG/PI at totally different temperatures (293 Ok, 270 Ok, 223 Ok, 77 Ok) carried out by 180° peeling checks (backside proper). (Picture courtesy of the researchers)

Moreover, the proposed cryogenic switch technique allowed the switch of LIG onto different sorts of adhesive or non-adhesive hydrogels, indicating the universality of this switch expertise. However, solely the adhesive hydrogel shaped a mechanically steady binding interface particularly beneath the tensile pressure.

By means of the facile laser direct writing and cryogenic switch approach, multimodal sensor parts are built-in as a multifunctional wearable sensor sheet for on-skin in vitro monitoring. Moreover, the ultrathin and biocompatible traits of the micropatterned LIG-based nanocomposites permit to type the seamless contact with the guts of Sprague Dawley (SD) rats to in situ monitor cardiac alerts.

Offered by Zhejiang College as a Nanowerk unique

Determine 1: Design of ultrathin, antibacterial and biocompatible PPH hydrogel-enhanced stretchable nanocomposites for wearable and implantable bioelectronics. (Picture courtesy of the researchers)

“Standard LIG switch methodology requires the a lot bigger thickness (>45 µm) of elastomers or adhesive tapes to supply a powerful interfacial drive through the peeling-off course of, hindering the conformal bioelectronics purposes,” says Prof. Kaichen Xu, corresponding writer of this publication. “The mechanical restrictions in transferring LIG to elastomers are overcome by a cryogenic switch method at -196 °C utilizing an ultrathin and adhesive polyvinyl alcohol/phytic acid/honey (PPH) hydrogel”.

Throughout the quick cooling course of, the interfacial binding power between faulty porous graphene and the crystallized water inside hydrogel is enhanced, as illustrated by molecular dynamics (MD) calculations. Such a dramatical enhance in superficial binding drive at 77 Ok was additionally captured within the 180° peeling check. The utmost transient peeling drive of 160 N m-1 at 77 Ok was noticed, which was a lot larger than that (<10 N m-1) originated from the autologous adhesion of PPH on the ambient temperature (Determine 2).

Determine 1: Design of ultrathin, antibacterial and biocompatible PPH hydrogel-enhanced stretchable nanocomposites for wearable and implantable bioelectronics. (Picture courtesy of the researchers)

“Standard LIG switch methodology requires the a lot bigger thickness (>45 µm) of elastomers or adhesive tapes to supply a powerful interfacial drive through the peeling-off course of, hindering the conformal bioelectronics purposes,” says Prof. Kaichen Xu, corresponding writer of this publication. “The mechanical restrictions in transferring LIG to elastomers are overcome by a cryogenic switch method at -196 °C utilizing an ultrathin and adhesive polyvinyl alcohol/phytic acid/honey (PPH) hydrogel”.

Throughout the quick cooling course of, the interfacial binding power between faulty porous graphene and the crystallized water inside hydrogel is enhanced, as illustrated by molecular dynamics (MD) calculations. Such a dramatical enhance in superficial binding drive at 77 Ok was additionally captured within the 180° peeling check. The utmost transient peeling drive of 160 N m-1 at 77 Ok was noticed, which was a lot larger than that (<10 N m-1) originated from the autologous adhesion of PPH on the ambient temperature (Determine 2).

Determine 2: Schematic of LIG switch on ultrathin PPH movies (thickness of 1.0~1.5 μm) by way of a cryogenic switch method (left graph). The superficial binding power was calculated primarily based on MD simulations. Calculated binding power of electrostatic interplay and Van der Waals interplay between the SDG, LDG and waters through the cooling course of (prime proper). The adhesion drive of PPH/PI and LIG/PI at totally different temperatures (293 Ok, 270 Ok, 223 Ok, 77 Ok) carried out by 180° peeling checks (backside proper). (Picture courtesy of the researchers)

Moreover, the proposed cryogenic switch technique allowed the switch of LIG onto different sorts of adhesive or non-adhesive hydrogels, indicating the universality of this switch expertise. However, solely the adhesive hydrogel shaped a mechanically steady binding interface particularly beneath the tensile pressure.

By means of the facile laser direct writing and cryogenic switch approach, multimodal sensor parts are built-in as a multifunctional wearable sensor sheet for on-skin in vitro monitoring. Moreover, the ultrathin and biocompatible traits of the micropatterned LIG-based nanocomposites permit to type the seamless contact with the guts of Sprague Dawley (SD) rats to in situ monitor cardiac alerts.

Offered by Zhejiang College as a Nanowerk unique

Determine 2: Schematic of LIG switch on ultrathin PPH movies (thickness of 1.0~1.5 μm) by way of a cryogenic switch method (left graph). The superficial binding power was calculated primarily based on MD simulations. Calculated binding power of electrostatic interplay and Van der Waals interplay between the SDG, LDG and waters through the cooling course of (prime proper). The adhesion drive of PPH/PI and LIG/PI at totally different temperatures (293 Ok, 270 Ok, 223 Ok, 77 Ok) carried out by 180° peeling checks (backside proper). (Picture courtesy of the researchers)

Moreover, the proposed cryogenic switch technique allowed the switch of LIG onto different sorts of adhesive or non-adhesive hydrogels, indicating the universality of this switch expertise. However, solely the adhesive hydrogel shaped a mechanically steady binding interface particularly beneath the tensile pressure.

By means of the facile laser direct writing and cryogenic switch approach, multimodal sensor parts are built-in as a multifunctional wearable sensor sheet for on-skin in vitro monitoring. Moreover, the ultrathin and biocompatible traits of the micropatterned LIG-based nanocomposites permit to type the seamless contact with the guts of Sprague Dawley (SD) rats to in situ monitor cardiac alerts.

Offered by Zhejiang College as a Nanowerk unique

Turn out to be a Highlight visitor writer! Be a part of our giant and rising group of visitor contributors. Have you ever simply printed a scientific paper or produce other thrilling developments to share with the nanotechnology group? Right here is find out how to publish on nanowerk.com.