Engineers at Duke College have produced the world’s first absolutely recyclable printed electronics that exchange using chemical substances with water within the fabrication course of. By bypassing the necessity for hazardous chemical substances, the demonstration factors down a path business may comply with to scale back its environmental footprint and human well being dangers.

The analysis appeared on-line Feb. 28 within the journal Nano Letters.

One of many dominant challenges going through any electronics producer is efficiently securing a number of layers of parts on high of one another, which is essential to creating advanced units. Getting these layers to stay collectively could be a irritating course of, significantly for printed electronics.

“In the event you’re making a peanut butter and jelly sandwich, one layer on both slice of bread is simple,” defined Aaron Franklin, the Addy Professor of Electrical and Laptop Engineering at Duke, who led the research. “However when you put the jelly down first after which attempt to unfold peanut butter on high of it, overlook it, the jelly will not keep put and can intermix with the peanut butter. Placing layers on high of one another is just not as straightforward as placing them down on their very own—however that is what it’s important to do if you wish to construct digital units with printing.”

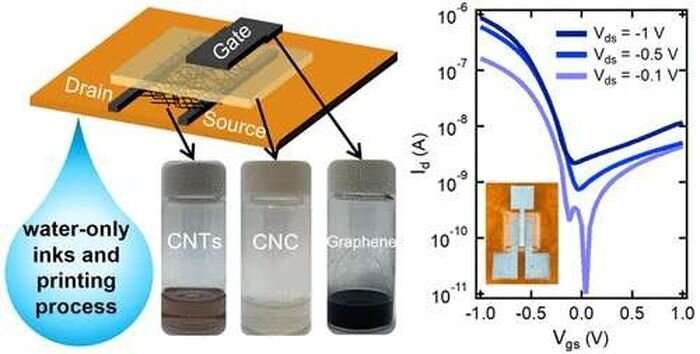

In earlier work, Franklin and his group demonstrated the primary absolutely recyclable printed electronics. The units used three carbon-based inks: semiconducting carbon nanotubes, conductive graphene and insulating nanocellulose. In making an attempt to adapt the unique course of to solely use water, the carbon nanotubes introduced the biggest problem.

To make a water-based ink by which the carbon nanotubes do not clump collectively and unfold evenly on a floor, a surfactant much like detergent is added. The ensuing ink, nonetheless, doesn’t create a layer of carbon nanotubes dense sufficient for a excessive present of electrons to journey throughout.

“You need the carbon nanotubes to appear to be al dente spaghetti strewn down on a flat floor,” mentioned Franklin. “However with a water-based ink, they appear extra like they have been taken one-by-one and tossed on a wall to test for doneness. If we have been utilizing chemical substances, we may simply print a number of passes time and again till there have been sufficient nanotubes. However water does not work that manner. We may do it 100 instances and there’d nonetheless be the identical density as the primary time.”

It is because the surfactant used to maintain the carbon nanotubes from clumping additionally prevents extra layers from adhering to the primary. In a conventional manufacturing course of, these surfactants could be eliminated utilizing both very excessive temperatures, which takes a variety of power, or harsh chemical substances, which might pose human and environmental well being dangers. Franklin and his group wished to keep away from each.

Within the paper, Franklin and his group develop a cyclical course of by which the system is rinsed with water, dried in comparatively low warmth and printed on once more. When the quantity of surfactant used within the ink can also be tuned down, the researchers present that their inks and processes can create absolutely purposeful, absolutely recyclable, absolutely water-based transistors.

In comparison with a resistor or capacitor, a transistor is a comparatively advanced laptop part utilized in units akin to energy management or logic circuits and sensors. Franklin explains that by demonstrating a transistor first, he hopes to sign to the remainder of the sector that there’s a viable path towards making some electronics manufacturing processes rather more environmentally pleasant.

Franklin has already confirmed that just about 100% of the carbon nanotubes and graphene utilized in printing might be recovered and reused in the identical course of, shedding little or no of the substances or their efficiency viability. As a result of nanocellulose is produced from wooden, it will probably merely be recycled or biodegraded like paper. And whereas the method does use a variety of water, it is not almost as a lot as what’s required to cope with the poisonous chemical substances utilized in conventional fabrication strategies.

In accordance with a United Nations estimate, lower than 1 / 4 of the hundreds of thousands of kilos of electronics thrown away annually is recycled. And the issue is just going to worsen because the world finally upgrades to 6G units and the Web of Issues (IoT) continues to increase. So any dent that might be made on this rising mountain of digital trash is vital to pursue.

Whereas extra work should be completed, Franklin says the strategy might be used within the manufacturing of different digital parts just like the screens and shows that at the moment are ubiquitous to society. Each digital show has a backplane of thin-film transistors comparable to what’s demonstrated within the paper. The present fabrication know-how is high-energy and depends on hazardous chemical substances in addition to poisonous gasses. All the business has been flagged for instant consideration by the US Environmental Safety Company.

“The efficiency of our thin-film transistors does not match one of the best presently being manufactured, however they’re aggressive sufficient to point out the analysis group that we must always all be doing extra work to make these processes extra environmentally pleasant,” Franklin mentioned.

Extra info:

Shiheng Lu et al, All-Carbon Skinny-Movie Transistors Utilizing Water-Solely Printing, Nano Letters (2023). DOI: 10.1021/acs.nanolett.2c04196

Offered by

Duke College

Quotation:

Totally recyclable printed electronics ditch poisonous chemical substances for water (2023, April 6)

retrieved 7 April 2023

from https://phys.org/information/2023-04-fully-recyclable-electronics-ditch-toxic.html

This doc is topic to copyright. Aside from any honest dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for info functions solely.