Right here at Linked World, we have now lengthy talked about the benefits of industrial 3D printing in manufacturing. Now with sustainability additionally on the forefront of everybody’s minds, the alternatives are much more advantageous.

However first, let’s look again to look ahead, as I all the time love to do. As most of us know from expertise, conventional desktop CAD (computer-aided design) and engineering software program was developed for conventional manufacturing strategies. This has required engineers to have entry to an costly, high-performance workstation within the workplace.

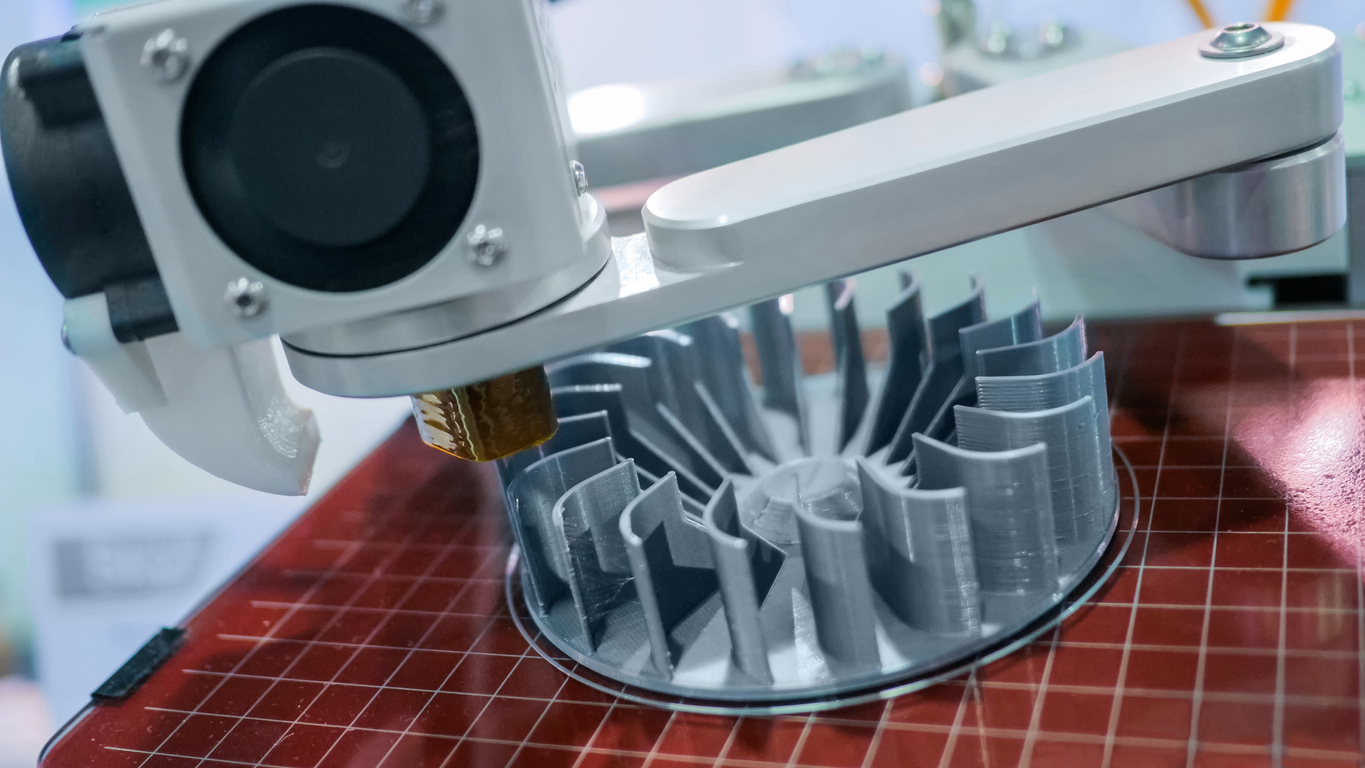

Prior to now a number of years, we have now seen the rise of 3D printing, which presents new alternatives to construct issues with complicated shapes. Grand View Analysis suggests the worldwide 3D printing market measurement was valued at $16.75 billion in 2022 and is projected to develop at an annual fee of 23.3% from 2023 to 2030.

That is partly as a result of know-how benefiting producers by way of prototyping, designing of the construction and finish merchandise, modeling, and time to market. Consequently, the manufacturing bills have diminished significantly, and the producers are able to supply higher merchandise at affordable costs. Because of these advantages, the demand for 3D printers is anticipated to be prompted extra within the coming years.

The problem is a spot nonetheless exists between 3D printing {hardware} capabilities and the software program to reap the benefits of the potential. This has prevented large utilization and adoption of 3D printing for manufacturing functions.

END LINKEDIN HERE

To assist tackle this, Metafold has raised $1.78 million in seed funding. The corporate has developed an ultra-precise, lightning-speed geometry computation engine for outputting correct designs for 3D printing complicated elements. The corporate’s cloud-based SaaS (software-as-a-service) platform is accessible on any gadget, making it straightforward for groups to provide optimized elements with the online utility or by leveraging an API (utility programming interface) to construct customized instruments and integrations.

By this superior geometry assist, Metafold allows producers to make use of much less uncooked materials and produce lighter, extra environment friendly elements which use much less power—each of which contribute to serving to clients obtain their sustainability objectives.

The funding comes as the corporate has gained speedy traction inside numerous key manufacturing markets corresponding to biotech and retail, supporting its clients’ have to design, take a look at, and produce extremely optimized buildings. The corporate plans to make use of the funds to deepen its first ideas strategy to unravel powerful geometry issues which are presently holding again 3D printing from mainstream adoption.

As applied sciences proceed to advance, new alternatives will current themselves for producers. Now could be the time to maneuver from conventional manufacturing processes to extra superior manufacturing processes, as know-how is advancing, and the market is demanding new, progressive merchandise. Amid a employee scarcity, such know-how may help pace time to market and ship the time and value financial savings that producers are so desperately searching for in immediately’s related period. How will your organization reply?

Need to tweet about this text? Use hashtags #IoT #sustainability #AI #5G #cloud #edge #futureofwork #digitaltransformation #inexperienced #ecosystem #environmental #circularworld #3Dprinting #manufacturing