“We introduced this idea robotic to those giant, worldwide exhibits to get accelerated enter from clients, and we weren’t upset,” says Lars. “We obtained speedy and in depth suggestions from dozens of shoppers not solely in these anticipated industries, however from others as properly, a few of which we hadn’t even thought of. A few of these had been potential clients who had been keen to clarify why they needed to make use of cobots however couldn’t – and what we might do to repair that.”

Lars explains how this method is vital to UR’s new agile processes. “We’d like to have the ability to adapt as we go, altering plans primarily based on knowledge or suggestions as we obtain it,” Lars provides. “In a waterfall method to growth, we put out necessities and spent two years following them. Now we’re working in parallel with our necessities so we will constantly launch merchandise and updates which might be in tune with buyer wants. We’re not a black field anymore.”

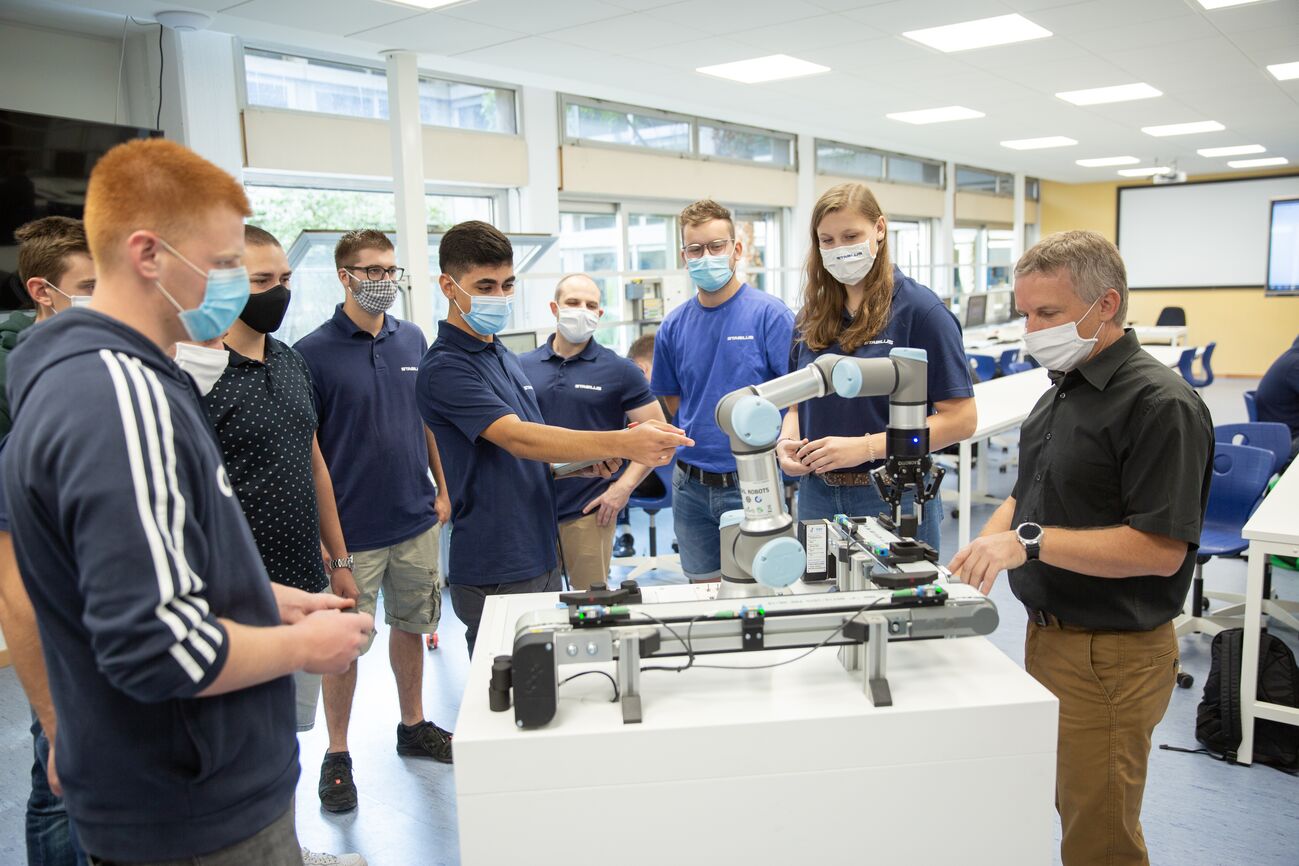

Making automation extra simple than ever earlier than

Whereas this method might end in particular cobot fashions to fulfill particular wants, Lars’ groups are additionally how they will proceed to make cobots simpler to make use of for present processes. “We’re all the time in search of methods to make utilizing cobots simpler and extra intuitive,” says Lars. “The better it’s, the sooner the deployment time, and the sooner clients can begin to tackle their functions.” That’s true for each finish customers and the ecosystem companions, who assist make the journey smoother for patrons.

PolyScope X was showcased at IMTS 2022 as a style of future software program capabilities. In the identical manner that UR confirmed its ‘clear’ idea cobot to get suggestions, the corporate exhibited its new programming expertise to study from clients and companions. With extra enter from beta clients, PolyScope X will make it simpler for all CNC machine outlets, and particularly high-mix, low-volume outlets, to get custom-made, configurable packages with out the necessity to re-program and with changeover instances at most 10 minutes. And for widespread functions similar to machine tending, PolyScope X can assist clients go from unboxing to manufacturing in eight hours or much less as soon as the CNC machine is ready for integration.

With PolyScope X, UR’s system integrators, OEMs, and UR+ companions get an even bigger and higher toolbox to create custom-made options for his or her clients. Integrators and companions will be capable of develop their very own templates and program code modules, enhancing their capability to create a totally configurable operator interface for his or her turnkey options. Finally, they’ll be capable of higher assist their clients do extra and deal with adjustments in manufacturing with out the necessity to reprogram.