Researchers from Carnegie Mellon College and the Chinese language College of Hong Kong have developed a method for creating ultrahigh-resolution, advanced 3D nanostructures out of varied supplies.

Carnegie Mellon College’s Yongxin (Leon) Zhao and the Chinese language College of Hong Kong’s Shih-Chi Chen have an enormous concept for manufacturing nanodevices.

Zhao’s Biophotonics Lab develops novel methods to check organic and pathological processes in cells and tissues. By a course of known as enlargement microscopy, the lab works to advance methods to proportionally enlarge microscopic samples embedded in a hydrogel, permitting researchers to have the ability to view fantastic particulars with out upgrading their microscopes.

In 2019, an inspiring dialog with Shih-Chi Chen, who was visiting Carnegie Mellon as an invited speaker and is a professor on the Chinese language College of Hong Kong’s Division of Mechanical and Automation Engineering, sparked a collaboration between the 2 researchers. They thought they may use their mixed experience to seek out novel options for the long-standing problem in microfabrication: creating methods to cut back the dimensions of printable nanodevices to as small as 10s of nanometers or a number of atoms thick.

Their resolution is the alternative of enlargement microscopy: create the 3D sample of a fabric in hydrogel and shrink it for nanoscale decision.

“Shih-Chi is understood for inventing the ultrafast two-photon lithography system,” stated Zhao, the Eberly Household Profession Growth Affiliate Professor of Organic Sciences. “We met throughout his go to to Carnegie Mellon and determined to mix our methods and experience to pursue this radical concept.”

The outcomes of the collaboration open new doorways for designing subtle nanodevices and are revealed within the journal Science.

Whereas typical 3D nanoscale printers focus a laser level to serially course of supplies and take a very long time to finish a design, Chen’s invention adjustments the width of the laser’s pulse to type patterned mild sheets, permitting for a complete picture containing a whole bunch of 1000’s of pixels (voxels) to be printed without delay with out compromising the axial decision.

The manufacturing approach known as femtosecond venture two-photon lithography, or FP-TPL. The tactic is as much as 1,000 instances sooner than earlier nanoprinting methods and will result in cost-effective massive scale nanoprinting to be used in in biotechnology, photonics or nanodevices.

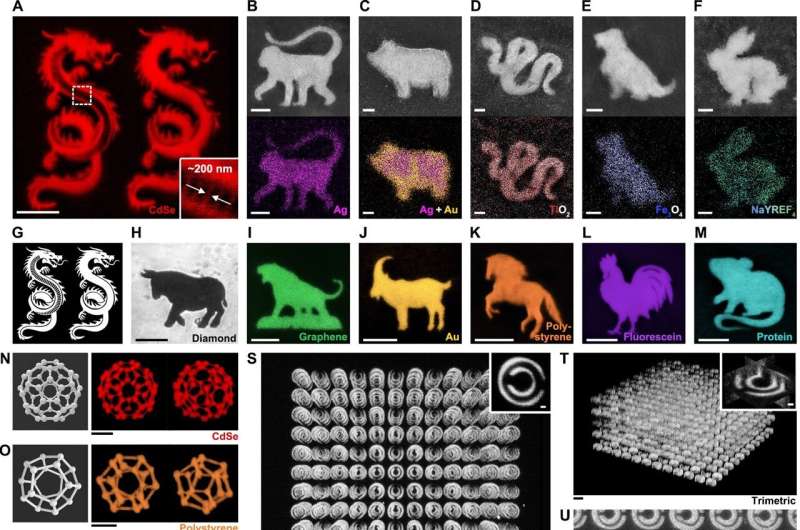

For the method, researchers would direct the femtosecond two-photon laser to switch the community construction and pore dimension of the hydrogel, which then creates boundaries for water-dispersible supplies. The hydrogel would then be immersed in water containing nanoparticles of steel, alloys, diamond, molecular crystals, polymers or fountain pen ink.

“By fortuitous happenstance, the nanomaterials we tried had been all attracted routinely to the printed sample in hydrogel and assembled fantastically,” Zhao stated. “Because the gel shrinks and dehydrates, the supplies grow to be much more densely packed and join to one another.”

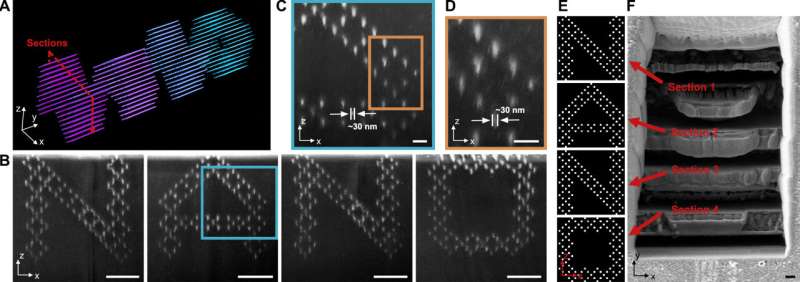

For instance, if a printed hydrogel is positioned right into a silver nanoparticle resolution, the silver nanoparticles self-assemble to the gel alongside the laser-printed sample. Because the gel dries out, it may possibly shrink to as much as 13 instances its authentic dimension, making the silver dense sufficient to type a nano silver wire and conduct electrical energy, Zhao stated.

As a result of the gels are three-dimensional, printed patterns might be as properly.

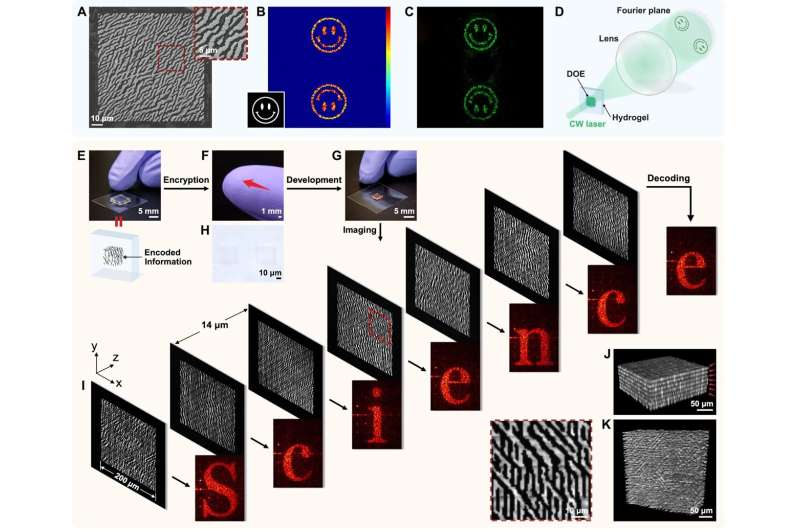

As an illustration of the approach’s use for encrypted optical storage—comparable to how CDs and DVDs are written and skim with a laser—the group designed and constructed a seven-layer 3D nanostructure that learn “SCIENCE” after it was optically decrypted.

Every layer contained a 200×200-pixel hologram of a letter. After shrinking the pattern the complete construction seems as a translucent rectangle below an optical microscope. One would want the best info on how a lot to increase the pattern and the place to shine a light-weight by to learn the data.

“Primarily based on our outcome, the approach can pack 5 petabits value of knowledge in a tiny cubic centimeter of area. That is roughly 2.5 instances of all U.S. tutorial analysis libraries mixed.” he stated.

Zhao stated that sooner or later the researchers’ aim is to construct practical nanodevices with a number of supplies.

“In the long run we want to use the brand new expertise to manufacture practical nanodevices, like nanocircuits, nanobiosensors, and even nanorobots for various purposes,” Zhao stated. “We’re solely restricted by our creativeness.”

Extra info:

Fei Han et al, Three-dimensional nanofabrication with ultrafast laser patterning and kinetically regulated materials meeting, Science (2022). DOI: 10.1126/science.abm8420. www.science.org/doi/10.1126/science.abm8420

Supplied by

Carnegie Mellon College

Quotation:

Shrinking hydrogels enlarge nanofabrication choices (2022, December 22)

retrieved 29 December 2022

from https://phys.org/information/2022-12-hydrogels-enlarge-nanofabrication-options.html

This doc is topic to copyright. Other than any honest dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is offered for info functions solely.