Nov 08, 2023

A novel nanosheet developed at Berkeley Lab guarantees to advance sustainable manufacturing and prolong product shelf life.

The fabric, overcoming conventional stacking defects, permits a flexible protecting barrier for electronics and client items.

Leveraging excessive entropy in materials blends, the brand new nanosheets self-assemble effectively, probably impacting varied industries.

Experiments display the nanosheet’s potential as a dielectric materials and as a filter for enhancing indoor air high quality.

The fabric’s manufacturing course of is designed for recyclability, with future enhancements to incorporate colour tunability.

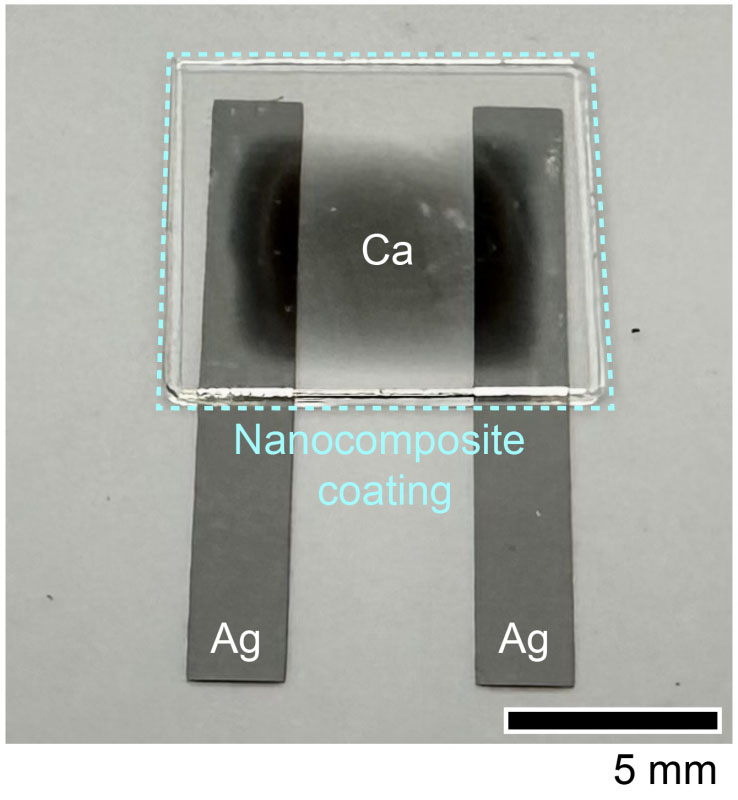

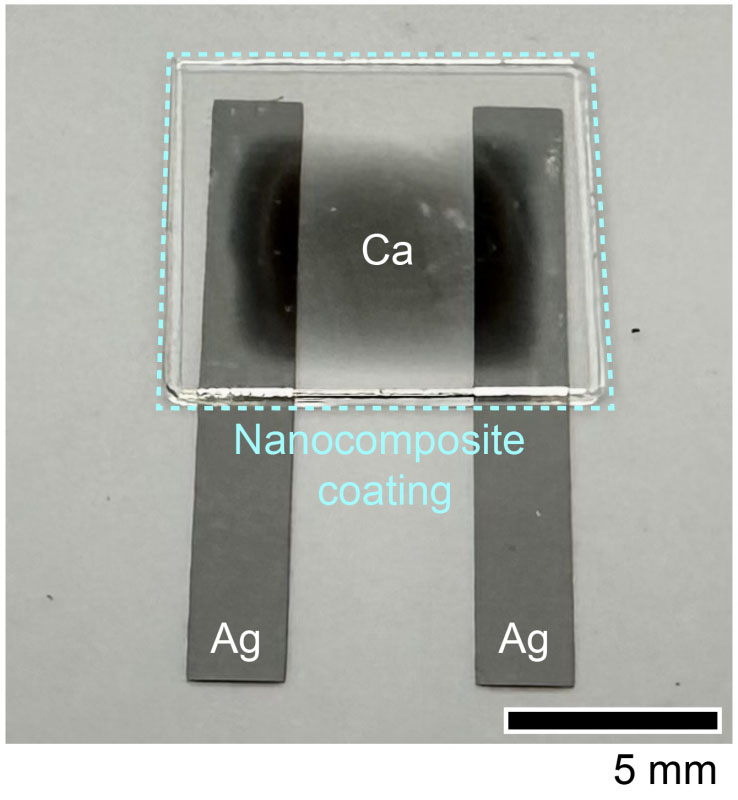

Microelectronic gadget fabricated within the Electrical Engineering and Laptop Science Division at UC Berkeley. Electrical calcium assessments demonstrated the self-assembling nanosheet’s potential as an oxygen barrier for microelectronics akin to thin-film photo voltaic supplies referred to as natural photovoltaics. (Picture: Jasmine Jan, UC Berkeley)

Microelectronic gadget fabricated within the Electrical Engineering and Laptop Science Division at UC Berkeley. Electrical calcium assessments demonstrated the self-assembling nanosheet’s potential as an oxygen barrier for microelectronics akin to thin-film photo voltaic supplies referred to as natural photovoltaics. (Picture: Jasmine Jan, UC Berkeley)

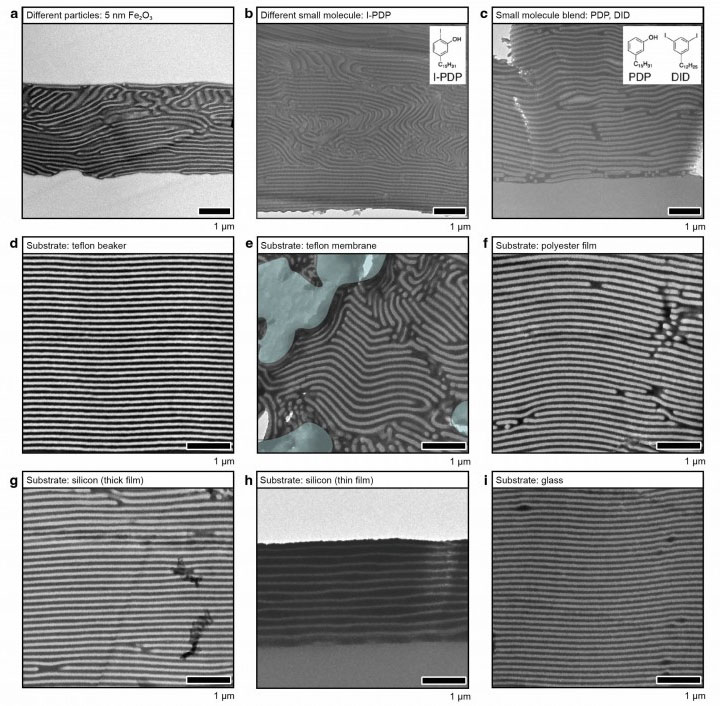

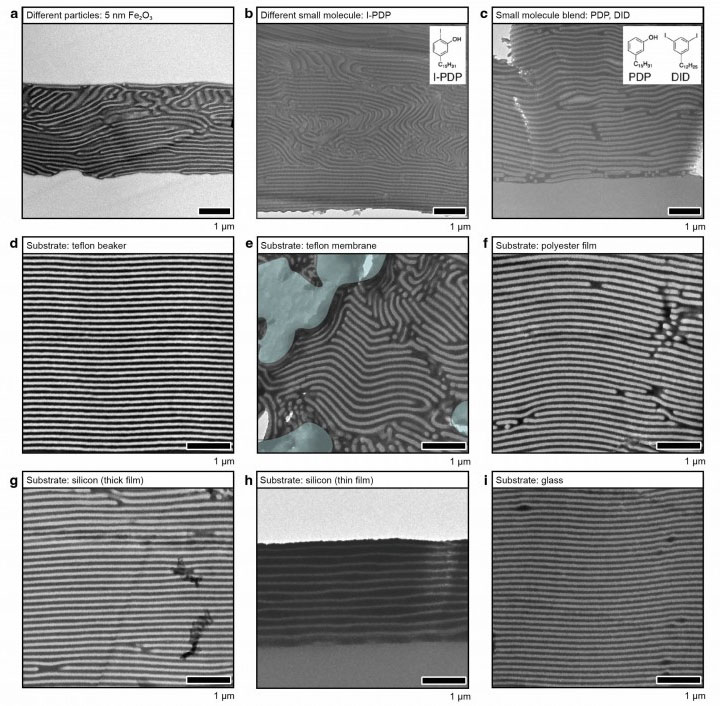

Transmission electron microscope (TEM) photos of the brand new 2D nanosheet as a barrier coating that self-assembles on quite a lot of substrates together with a Teflon beaker and membrane, polyester movie, thick and skinny silicon movies, and glass. The TEM experiments had been carried out at UC Berkeley’s Electron Microscopy Laboratory. (Picture: Emma Vargo et al./Berkeley Lab)

Experiments at Oak Ridge Nationwide Laboratory’s Spallation Neutron Supply helped the researchers perceive the early, coarse levels of the blends’ self-assembly. Because the solvent evaporates, the small particles coalesce and spontaneously arrange, coarsely templating layers, after which solidify into dense nanosheets. On this means, the ordered layers type concurrently relatively than being stacked one after the other in a serial course of. The small items solely want to maneuver brief distances to get organized and shut gaps, avoiding the issues of shifting bigger “tiles” and the inevitable gaps between them.

From a earlier research led by Xu (ACS Nano, “Diversifying Composition Results in Hierarchical Composites with Design Flexibility and Structural Constancy”), the researchers knew that combining nanocomposite blends containing a number of “constructing blocks” of varied sizes and chemistries, together with advanced polymers and nanoparticles, wouldn’t solely adapt to impurities but additionally unlock a system’s entropy, the inherent dysfunction in mixtures of supplies that Xu’s group harnessed to distribute the fabric’s constructing blocks.

The brand new research builds on this earlier work. The researchers predicted that the advanced mix used for the present research would have two very best properties: Along with having excessive entropy to drive the self-assembly of a stack of a whole lot of nanosheets shaped concurrently, additionally they anticipated that the brand new nanosheet system can be minimally affected by totally different floor chemistries. This, they reasoned, would permit the identical mix to type a protecting barrier on quite a lot of surfaces, such because the glass display of an digital gadget, or a polyester masks.

Transmission electron microscope (TEM) photos of the brand new 2D nanosheet as a barrier coating that self-assembles on quite a lot of substrates together with a Teflon beaker and membrane, polyester movie, thick and skinny silicon movies, and glass. The TEM experiments had been carried out at UC Berkeley’s Electron Microscopy Laboratory. (Picture: Emma Vargo et al./Berkeley Lab)

Experiments at Oak Ridge Nationwide Laboratory’s Spallation Neutron Supply helped the researchers perceive the early, coarse levels of the blends’ self-assembly. Because the solvent evaporates, the small particles coalesce and spontaneously arrange, coarsely templating layers, after which solidify into dense nanosheets. On this means, the ordered layers type concurrently relatively than being stacked one after the other in a serial course of. The small items solely want to maneuver brief distances to get organized and shut gaps, avoiding the issues of shifting bigger “tiles” and the inevitable gaps between them.

From a earlier research led by Xu (ACS Nano, “Diversifying Composition Results in Hierarchical Composites with Design Flexibility and Structural Constancy”), the researchers knew that combining nanocomposite blends containing a number of “constructing blocks” of varied sizes and chemistries, together with advanced polymers and nanoparticles, wouldn’t solely adapt to impurities but additionally unlock a system’s entropy, the inherent dysfunction in mixtures of supplies that Xu’s group harnessed to distribute the fabric’s constructing blocks.

The brand new research builds on this earlier work. The researchers predicted that the advanced mix used for the present research would have two very best properties: Along with having excessive entropy to drive the self-assembly of a stack of a whole lot of nanosheets shaped concurrently, additionally they anticipated that the brand new nanosheet system can be minimally affected by totally different floor chemistries. This, they reasoned, would permit the identical mix to type a protecting barrier on quite a lot of surfaces, such because the glass display of an digital gadget, or a polyester masks.

Scanning transmission electron microscope (STEM) tomography reconstruction experiments on the Molecular Foundry revealed steady 2D nanosheets folded at a pointy angle. (Picture: Emma Vargo et al./Berkeley Lab)

Primarily based on these quantitative research, the researchers fabricated barrier coatings by making use of a dilute answer of polymers, natural small molecules, and nanoparticles to varied substrates – a Teflon beaker and membrane, polyester movie, thick and skinny silicon movies, glass, and even a prototype of a microelectronic gadget – after which controlling the speed of movie formation.

Transmission electron microscope experiments at Berkeley Lab’s Molecular Foundry present that by the point the solvent had evaporated, a extremely ordered layered construction of greater than 200 stacked nanosheets with very low defect density had self-assembled on the substrates. The researchers additionally succeeded in making every nanosheet 100 nanometers thick with few holes and gaps, which makes the fabric notably efficient at stopping the passage of water vapor, risky natural compounds, and electrons, Vargo stated.

Different experiments on the Molecular Foundry confirmed that the fabric has nice potential as a dielectric, an insulating “electron barrier” materials generally utilized in capacitors for vitality storage and computing purposes.

In collaboration with researchers in Berkeley Lab’s Vitality Applied sciences Space, Xu and crew demonstrated that when the fabric is used to coat porous Teflon membranes (a standard materials used to make protecting face masks), it’s extremely efficient in filtering out risky natural compounds that may compromise indoor air high quality.

And in a closing experiment within the Xu lab, the researchers confirmed that the fabric will be redissolved and recast to provide a recent barrier coating.

Now that they’ve efficiently demonstrated find out how to simply synthesize a flexible practical materials for varied industrial purposes from a single nanomaterial, the researchers plan to finetune the fabric’s recyclability and add colour tunability (it at present is available in blue) to its repertoire.

Scanning transmission electron microscope (STEM) tomography reconstruction experiments on the Molecular Foundry revealed steady 2D nanosheets folded at a pointy angle. (Picture: Emma Vargo et al./Berkeley Lab)

Primarily based on these quantitative research, the researchers fabricated barrier coatings by making use of a dilute answer of polymers, natural small molecules, and nanoparticles to varied substrates – a Teflon beaker and membrane, polyester movie, thick and skinny silicon movies, glass, and even a prototype of a microelectronic gadget – after which controlling the speed of movie formation.

Transmission electron microscope experiments at Berkeley Lab’s Molecular Foundry present that by the point the solvent had evaporated, a extremely ordered layered construction of greater than 200 stacked nanosheets with very low defect density had self-assembled on the substrates. The researchers additionally succeeded in making every nanosheet 100 nanometers thick with few holes and gaps, which makes the fabric notably efficient at stopping the passage of water vapor, risky natural compounds, and electrons, Vargo stated.

Different experiments on the Molecular Foundry confirmed that the fabric has nice potential as a dielectric, an insulating “electron barrier” materials generally utilized in capacitors for vitality storage and computing purposes.

In collaboration with researchers in Berkeley Lab’s Vitality Applied sciences Space, Xu and crew demonstrated that when the fabric is used to coat porous Teflon membranes (a standard materials used to make protecting face masks), it’s extremely efficient in filtering out risky natural compounds that may compromise indoor air high quality.

And in a closing experiment within the Xu lab, the researchers confirmed that the fabric will be redissolved and recast to provide a recent barrier coating.

Now that they’ve efficiently demonstrated find out how to simply synthesize a flexible practical materials for varied industrial purposes from a single nanomaterial, the researchers plan to finetune the fabric’s recyclability and add colour tunability (it at present is available in blue) to its repertoire.

(Nanowerk Information) A brand new self-assembling nanosheet may radically speed up the event of practical and sustainable nanomaterials for electronics, vitality storage, well being and security, and extra.

Key Takeaways

Microelectronic gadget fabricated within the Electrical Engineering and Laptop Science Division at UC Berkeley. Electrical calcium assessments demonstrated the self-assembling nanosheet’s potential as an oxygen barrier for microelectronics akin to thin-film photo voltaic supplies referred to as natural photovoltaics. (Picture: Jasmine Jan, UC Berkeley)

Microelectronic gadget fabricated within the Electrical Engineering and Laptop Science Division at UC Berkeley. Electrical calcium assessments demonstrated the self-assembling nanosheet’s potential as an oxygen barrier for microelectronics akin to thin-film photo voltaic supplies referred to as natural photovoltaics. (Picture: Jasmine Jan, UC Berkeley)

The Analysis

Developed by a crew led by Lawrence Berkeley Nationwide Laboratory (Berkeley Lab), the brand new self-assembling nanosheet may considerably prolong the shelf lifetime of client merchandise. And since the brand new materials is recyclable, it may additionally allow a sustainable manufacturing method that retains single-use packaging and electronics out of landfills. The crew is the primary to efficiently develop a multipurpose, high-performance barrier materials from self-assembling nanosheets. The breakthrough was reported on-line within the journal Nature (“Practical composites by programming entropy-driven nanosheet progress”). “Our work overcomes a longstanding hurdle in nanoscience – scaling up nanomaterial synthesis into helpful supplies for manufacturing and industrial purposes,” stated Ting Xu, the principal investigator who led the research. “It’s actually thrilling as a result of this has been a long time within the making.” Xu is a school senior scientist in Berkeley Lab’s Supplies Sciences Division, and professor of chemistry and supplies science and engineering at UC Berkeley. One problem in harvesting nanoscience to create practical supplies is that many small items want to return collectively in order that the nanomaterial can develop massive sufficient to be helpful. And whereas stacking nanosheets is among the easiest methods to develop nanomaterials right into a product, “stacking defects” – gaps between the nanosheets – are unavoidable when working with current nanosheets or nanoplatelets. “In the event you visualize constructing a 3D construction from skinny, flat tiles, you will have layers up the peak of the construction, however you will even have gaps all through every layer wherever two tiles meet,” stated first writer Emma Vargo, a former graduate pupil researcher within the Xu group and now a postdoctoral scholar in Berkeley Lab’s Supplies Sciences Division. “It’s tempting to cut back the variety of gaps by making the tiles larger, however they grow to be tougher to work with,” Vargo stated. The brand new nanosheet materials overcomes the issue of stacking defects by skipping the serial stacked sheet method altogether. As a substitute, the crew combined blends of supplies which are recognized to self-assemble into small particles with alternating layers of the part supplies, suspended in a solvent. To design the system, the researchers used advanced blends of nanoparticles, small molecules, and block copolymer-based supramolecules, all of that are commercially obtainable. Transmission electron microscope (TEM) photos of the brand new 2D nanosheet as a barrier coating that self-assembles on quite a lot of substrates together with a Teflon beaker and membrane, polyester movie, thick and skinny silicon movies, and glass. The TEM experiments had been carried out at UC Berkeley’s Electron Microscopy Laboratory. (Picture: Emma Vargo et al./Berkeley Lab)

Experiments at Oak Ridge Nationwide Laboratory’s Spallation Neutron Supply helped the researchers perceive the early, coarse levels of the blends’ self-assembly. Because the solvent evaporates, the small particles coalesce and spontaneously arrange, coarsely templating layers, after which solidify into dense nanosheets. On this means, the ordered layers type concurrently relatively than being stacked one after the other in a serial course of. The small items solely want to maneuver brief distances to get organized and shut gaps, avoiding the issues of shifting bigger “tiles” and the inevitable gaps between them.

From a earlier research led by Xu (ACS Nano, “Diversifying Composition Results in Hierarchical Composites with Design Flexibility and Structural Constancy”), the researchers knew that combining nanocomposite blends containing a number of “constructing blocks” of varied sizes and chemistries, together with advanced polymers and nanoparticles, wouldn’t solely adapt to impurities but additionally unlock a system’s entropy, the inherent dysfunction in mixtures of supplies that Xu’s group harnessed to distribute the fabric’s constructing blocks.

The brand new research builds on this earlier work. The researchers predicted that the advanced mix used for the present research would have two very best properties: Along with having excessive entropy to drive the self-assembly of a stack of a whole lot of nanosheets shaped concurrently, additionally they anticipated that the brand new nanosheet system can be minimally affected by totally different floor chemistries. This, they reasoned, would permit the identical mix to type a protecting barrier on quite a lot of surfaces, such because the glass display of an digital gadget, or a polyester masks.

Transmission electron microscope (TEM) photos of the brand new 2D nanosheet as a barrier coating that self-assembles on quite a lot of substrates together with a Teflon beaker and membrane, polyester movie, thick and skinny silicon movies, and glass. The TEM experiments had been carried out at UC Berkeley’s Electron Microscopy Laboratory. (Picture: Emma Vargo et al./Berkeley Lab)

Experiments at Oak Ridge Nationwide Laboratory’s Spallation Neutron Supply helped the researchers perceive the early, coarse levels of the blends’ self-assembly. Because the solvent evaporates, the small particles coalesce and spontaneously arrange, coarsely templating layers, after which solidify into dense nanosheets. On this means, the ordered layers type concurrently relatively than being stacked one after the other in a serial course of. The small items solely want to maneuver brief distances to get organized and shut gaps, avoiding the issues of shifting bigger “tiles” and the inevitable gaps between them.

From a earlier research led by Xu (ACS Nano, “Diversifying Composition Results in Hierarchical Composites with Design Flexibility and Structural Constancy”), the researchers knew that combining nanocomposite blends containing a number of “constructing blocks” of varied sizes and chemistries, together with advanced polymers and nanoparticles, wouldn’t solely adapt to impurities but additionally unlock a system’s entropy, the inherent dysfunction in mixtures of supplies that Xu’s group harnessed to distribute the fabric’s constructing blocks.

The brand new research builds on this earlier work. The researchers predicted that the advanced mix used for the present research would have two very best properties: Along with having excessive entropy to drive the self-assembly of a stack of a whole lot of nanosheets shaped concurrently, additionally they anticipated that the brand new nanosheet system can be minimally affected by totally different floor chemistries. This, they reasoned, would permit the identical mix to type a protecting barrier on quite a lot of surfaces, such because the glass display of an digital gadget, or a polyester masks.

Ease of self-assembly and excessive efficiency

To check the efficiency of the fabric as a barrier coating in a number of totally different purposes, the researchers enlisted the assistance of a number of the nation’s finest analysis amenities. Throughout experiments at Argonne Nationwide Laboratory’s Superior Photon Supply, the researchers mapped out how every part comes collectively, and quantified their mobilities and the style wherein every part strikes round to develop a practical materials. Scanning transmission electron microscope (STEM) tomography reconstruction experiments on the Molecular Foundry revealed steady 2D nanosheets folded at a pointy angle. (Picture: Emma Vargo et al./Berkeley Lab)

Primarily based on these quantitative research, the researchers fabricated barrier coatings by making use of a dilute answer of polymers, natural small molecules, and nanoparticles to varied substrates – a Teflon beaker and membrane, polyester movie, thick and skinny silicon movies, glass, and even a prototype of a microelectronic gadget – after which controlling the speed of movie formation.

Transmission electron microscope experiments at Berkeley Lab’s Molecular Foundry present that by the point the solvent had evaporated, a extremely ordered layered construction of greater than 200 stacked nanosheets with very low defect density had self-assembled on the substrates. The researchers additionally succeeded in making every nanosheet 100 nanometers thick with few holes and gaps, which makes the fabric notably efficient at stopping the passage of water vapor, risky natural compounds, and electrons, Vargo stated.

Different experiments on the Molecular Foundry confirmed that the fabric has nice potential as a dielectric, an insulating “electron barrier” materials generally utilized in capacitors for vitality storage and computing purposes.

In collaboration with researchers in Berkeley Lab’s Vitality Applied sciences Space, Xu and crew demonstrated that when the fabric is used to coat porous Teflon membranes (a standard materials used to make protecting face masks), it’s extremely efficient in filtering out risky natural compounds that may compromise indoor air high quality.

And in a closing experiment within the Xu lab, the researchers confirmed that the fabric will be redissolved and recast to provide a recent barrier coating.

Now that they’ve efficiently demonstrated find out how to simply synthesize a flexible practical materials for varied industrial purposes from a single nanomaterial, the researchers plan to finetune the fabric’s recyclability and add colour tunability (it at present is available in blue) to its repertoire.

Scanning transmission electron microscope (STEM) tomography reconstruction experiments on the Molecular Foundry revealed steady 2D nanosheets folded at a pointy angle. (Picture: Emma Vargo et al./Berkeley Lab)

Primarily based on these quantitative research, the researchers fabricated barrier coatings by making use of a dilute answer of polymers, natural small molecules, and nanoparticles to varied substrates – a Teflon beaker and membrane, polyester movie, thick and skinny silicon movies, glass, and even a prototype of a microelectronic gadget – after which controlling the speed of movie formation.

Transmission electron microscope experiments at Berkeley Lab’s Molecular Foundry present that by the point the solvent had evaporated, a extremely ordered layered construction of greater than 200 stacked nanosheets with very low defect density had self-assembled on the substrates. The researchers additionally succeeded in making every nanosheet 100 nanometers thick with few holes and gaps, which makes the fabric notably efficient at stopping the passage of water vapor, risky natural compounds, and electrons, Vargo stated.

Different experiments on the Molecular Foundry confirmed that the fabric has nice potential as a dielectric, an insulating “electron barrier” materials generally utilized in capacitors for vitality storage and computing purposes.

In collaboration with researchers in Berkeley Lab’s Vitality Applied sciences Space, Xu and crew demonstrated that when the fabric is used to coat porous Teflon membranes (a standard materials used to make protecting face masks), it’s extremely efficient in filtering out risky natural compounds that may compromise indoor air high quality.

And in a closing experiment within the Xu lab, the researchers confirmed that the fabric will be redissolved and recast to provide a recent barrier coating.

Now that they’ve efficiently demonstrated find out how to simply synthesize a flexible practical materials for varied industrial purposes from a single nanomaterial, the researchers plan to finetune the fabric’s recyclability and add colour tunability (it at present is available in blue) to its repertoire.