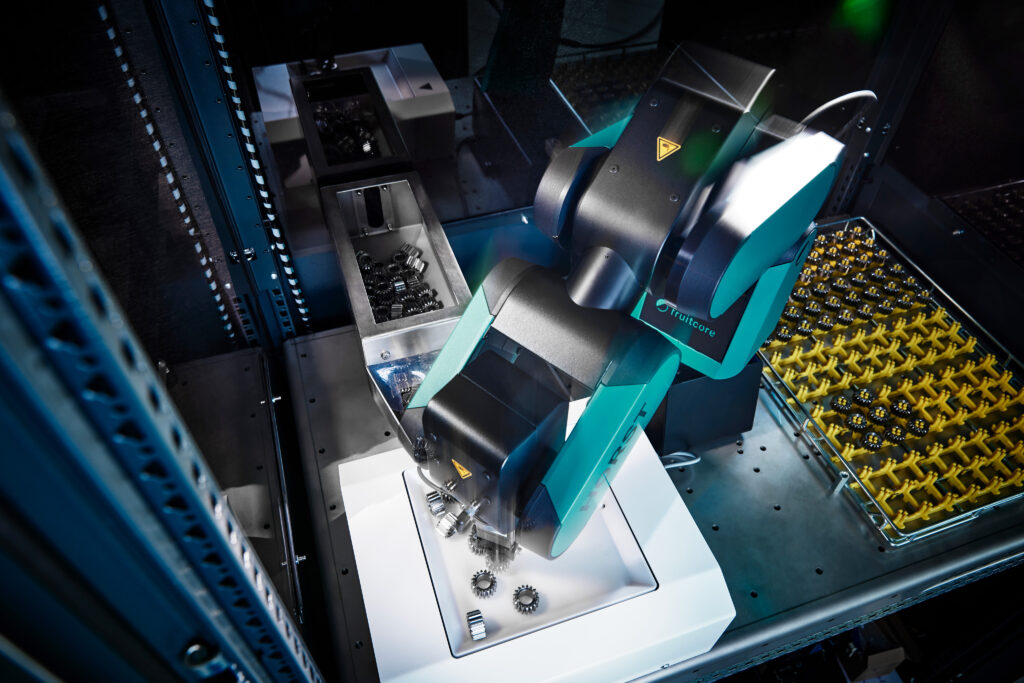

Constance, June twenty eighth, 2023 – fruitcore robotics takes industrial automation to a brand new degree with an progressive working system that makes use of the newest AI know-how. With horstOS, industrial firms have a brand new software at their disposal that assists them in each step of commissioning complete purposes with the clever industrial robotic HORST whereas considerably lowering complexity. With an built-in AI copilot, industrial firms can enhance the effectivity of their manufacturing processes and save time. „Generative AI is driving a metamorphosis of many activity areas. The brand new know-how will rework automation and supply our clients with a complete new automation expertise,“ says Patrick Heimburger, Managing Director (Chief Income Officer) of fruitcore robotics.

The brand new working system of fruitcore robotics simplifies and accelerates the configuration and administration of all parts concerned within the course of, the programming in addition to the operation of the completed utility. The whole management system of robots, parts and present industrial processes is carried out through a user-friendly interface by means of which their interplay is realized even extra simply. horstOS basically contains three interconnected areas: the part administration space, this system creation space and the method management system space. These three areas present customers with all of the features they should arrange and use their total crops rapidly, easy and effectively.

Within the part administration space, customers can seamlessly combine and centrally handle all parts related to an total plant, akin to grippers, digital camera programs and security programs, thanks to standardized interfaces. Including parts takes only one click on and is feasible for all parts which have an online app or a digital interface – whatever the producer. If standing data wants to be queried for one of many related parts, settings should be checked or adjustments must be made, this may be carried out easy through the robotic panel with horstOS because the central consumer interface. When customers change to this system creation space, they discover themselves within the intuitive horstFX working software program, by which they create the robotic’s program sequence with the mixing of all parts. As soon as this system sequence has been created, it may be began, stopped or paused within the course of management system. The method management system additionally permits customers to customise the operation and course of monitoring to their private wants and particular processes. Widgets can be utilized to indicate related course of knowledge, show the standing of related parts, and entry parameters that should be adjusted continuously. This provides customers full management over their automation course of.

Ask HORST Something – AI Copilot helps in all life phases of business robots

„Our new working system incorporates probably the most superior know-how and deep integration of synthetic intelligence. It units new requirements for the fast integration of business robots into processes akin to machine loading and unloading, high quality assurance, elements separation or adhesive and sealant utility, says Patrick Heimburger. With the AI Copilot in horstOS, customers get an clever assistant that gives real-time assist in pure language to efficiently cope the challenges of automation. Whether or not organising the robotic and different parts, troubleshooting, or suggesting program blocks and even writing complete packages, AI Copilot allows customers to rapidly and precisely discover options for his or her purposes and hold operations operating easily. For instance, if the consumer desires to know the right way to go the half place detected by the digital camera to the robotic, he can tackle this query to the AI Copilot through textual content immediate and obtain the corresponding code block inside a couple of moments.

The AI Copilot from fruitcore robotics is predicated on ChatGPT and has been specifically educated for business circumstances. It gives customers complete entry to all related directions, assist content material and software program documentation from fruitcore robotics. To be able to present customers with an optimum consumer expertise, the Constance-based firm focuses on steady enhancements of the AI Copilot’s capabilities.

Future-oriented automation with horstOS

The scope of horstOS can also be anticipated to develop steadily within the coming years. The modular construction of the working system already permits exterior software program and companies to be built-in with out nice effort. Person-specific software program packages and interfaces from OEMs can be seamlessly built-in. „By means of horstOS, the way forward for automation turns into a brand new actuality. The system gives intensive assist, even for these with little data, and considerably reduces the trouble required for setup, operation and after gross sales,“ explains Jens Riegger, Managing Director (CEO) of fruitcore robotics. „Our clever industrial robots should not solely designed to supply our clients the most effective return-on funding within the robotics market. Particularly towards the backdrop of the ever present scarcity of expert staff, they’re additionally designed to assist enhance productiveness and save useful time,“ says Jens Riegger.