Aug 10, 2023

(Nanowerk Information) Industrial biocatalysis is principally used for the manufacturing of prescribed drugs and particular chemical compounds. To advance this course of, researchers are engaged on new course of applied sciences. In biocatalysis, enzymes speed up the reactions as an alternative of chemical catalysts. This protects assets and vitality.

Present work is geared toward constantly offering giant portions of enzyme biocatalysts below circumstances which are as light as attainable. To realize environment friendly substance conversions, enzymes are immobilized in microstructured move reactors. They’re spatially fastened and certain to an inert materials. Therefore, their mobility is proscribed, which ends up in a better focus of enzymes and a better productiveness.

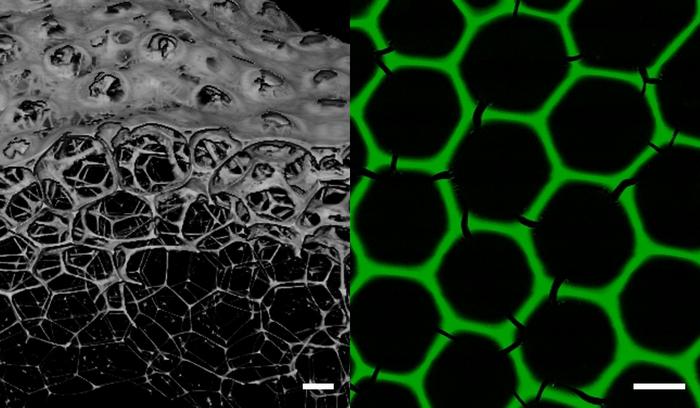

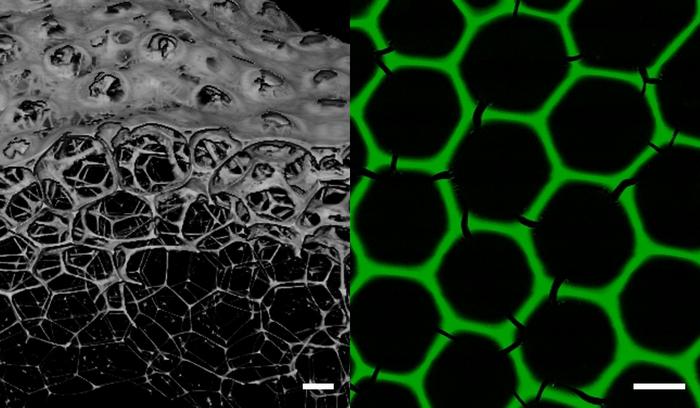

New biomaterials for industrial biocatalysis: Enzyme foams type three-dimensional porous networks with a steady hexagonal honeycomb construction. (Picture: Julian Hertel, KIT)

New biomaterials for industrial biocatalysis: Enzyme foams type three-dimensional porous networks with a steady hexagonal honeycomb construction. (Picture: Julian Hertel, KIT)

Foamed Microdroplets from Self-assembling Enzymes

Usually, foaming modifies the enzyme construction and enzymes lose their biocatalytic exercise. The brand new protein foams, nevertheless, have an incredible stability and exercise. Exercise is a measure of the effectiveness of the enzyme that ensures that the preliminary substances react with one another as rapidly as attainable. For the manufacturing of protein foams, two dehydrogenase enzymes are combined, which carry matching websites to spontaneously type a steady protein community. “Then, a gasoline move is added to this combine in a microfluidic chip for the managed formation of microscopic bubbles of uniform measurement,” explains Professor Christof Niemeyer from the Institute for Organic Interfaces 1. The froth with the uniform bubble measurement is utilized immediately onto plastic chips and dried, on account of which the proteins polymerize and type a steady hexagonal lattice. “These monodisperse all-enzyme foams are three-dimensional porous networks consisting of biocatalytically lively proteins completely,” Niemeyer says. The steady hexagonal honeycomb construction of the foams has a imply pore diameter of 160 µm and a thickness of the lamellae of 8 µm. It’s shaped by the uniform spherical bubbles after a couple of minutes. New biomaterials for industrial biocatalysis: Enzyme foams type three-dimensional porous networks with a steady hexagonal honeycomb construction. (Picture: Julian Hertel, KIT)

New biomaterials for industrial biocatalysis: Enzyme foams type three-dimensional porous networks with a steady hexagonal honeycomb construction. (Picture: Julian Hertel, KIT)