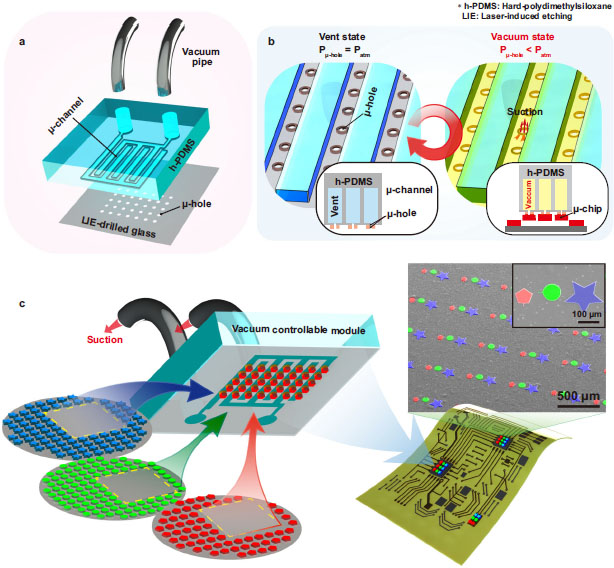

(Nanowerk Information) MicroLEDs are a light-weight supply for next-generation shows that make the most of inorganic LED chips with a measurement of lower than 100 µm. MicroLEDs have attracted an excessive amount of consideration because of their superior electrical/optical properties, reliability, and stability in comparison with standard shows corresponding to LCD, OLED, and QD. To commercialize microLEDs, switch printing expertise is crucial for rearranging microLED dies from a development substrate onto the ultimate substrate with a desired format and exact alignment. Nonetheless, earlier switch strategies nonetheless have many challenges corresponding to the necessity for added adhesives, misalignment, low switch yield, and chip harm. Professor Lee’s analysis group has developed a micro-vacuum assisted selective switch printing (µVAST) expertise to switch numerous microLED chips by adjusting the micro-vacuum suction power.

The analysis was printed in Nature Communications (“Common selective switch printing through micro-vacuum power”). The important thing expertise depends on a laser-induced etching (LIE) technique for forming 20 μm-sized micro-hole arrays with a excessive facet ratio on glass substrates at fabrication velocity of as much as 7,000 holes per second. The LIE-drilled glass is related to the vacuum channels, controlling the micro-vacuum power at desired gap arrays to selectively decide up and launch the microLEDs. Idea of micro-vacuum assisted selective switch printing (μVAST). (Picture: KAIST)

The micro-vacuum assisted switch printing accomplishes the next adhesion switchability in comparison with earlier switch strategies, enabling the meeting of micro-sized semiconductors with varied heterogeneous supplies, sizes, shapes, and thicknesses onto arbitrary substrates with excessive switch yields.

Professor Keon Jae Lee mentioned, “The micro-vacuum assisted switch supplies an attention-grabbing software for large-scale, selective integration of microscale high-performance inorganic semiconductors. At the moment, we’re investigating the switch printing of economic microLED chips with an ejector system for commercializing next-generation shows (Massive display screen TVs, versatile/stretchable units) and wearable phototherapy patches.”

Idea of micro-vacuum assisted selective switch printing (μVAST). (Picture: KAIST)

The micro-vacuum assisted switch printing accomplishes the next adhesion switchability in comparison with earlier switch strategies, enabling the meeting of micro-sized semiconductors with varied heterogeneous supplies, sizes, shapes, and thicknesses onto arbitrary substrates with excessive switch yields.

Professor Keon Jae Lee mentioned, “The micro-vacuum assisted switch supplies an attention-grabbing software for large-scale, selective integration of microscale high-performance inorganic semiconductors. At the moment, we’re investigating the switch printing of economic microLED chips with an ejector system for commercializing next-generation shows (Massive display screen TVs, versatile/stretchable units) and wearable phototherapy patches.”