Professor Wei Xiong’s group, from the Wuhan Nationwide Laboratory for Optoelectronics at Huazhong College of Science and Expertise, proposes a pioneering high-speed multi-photon polymerization lithography approach with a record-high 3D printing fee of seven.6 × 107 voxel s−1, which is almost one order of magnitude increased than earlier scanning multiphoton lithography (MPL).

Revealed in Worldwide Journal of Excessive Manufacturing (IJEM), this know-how, based mostly on acousto-optic scanning with spatial-switching (AOSS), not solely prints advanced 3D micro-nano buildings with an accuracy of 212 nm, but additionally achieves an unprecedented 3D printing fee of seven.6 × 107 voxel/s. It is like an artist portray a self-portrait in merely 5 minutes, the place each intricate element, down to every strand of hair, comes vividly to life.

“Processing pace and processing accuracy are essential efficiency parameters for evaluating micro-nano three-dimensional printing know-how, and this know-how has wonderful efficiency in each elements,” stated Prof. Wei Xiong. “This analysis supplies a possible technical route for attaining large-scale nano-3D printing sooner or later.”

The precision manufacturing of intricate and complicated three-dimensional micro-nano buildings serves as a foundational cornerstone for quite a few forefront disciplines. In mild of its inherent capability for true three-dimensional digital fabrication and nanoscale processing decision past the diffraction restrict, two-photon lithography(TPL) has constantly remained a focus of analysis inside the subject.

It has now discovered in depth purposes in cutting-edge domains together with three-dimensional metamaterial, micro-optical, microelectronic elements, and biomedical engineering.

Nonetheless, regardless of its excessive nanoscale decision capabilities, the restricted processing pace of TPL has persistently constrained its potential. For instance, the printing of a easy coin can usually lengthen over dozens of hours, a timeframe clearly insufficient for industrial manufacturing purposes.

Then Jiao started a collection of experimental research and ultimately discovered the acousto-optic deflector (AOD) because the centerpiece of the method to extend printing pace.

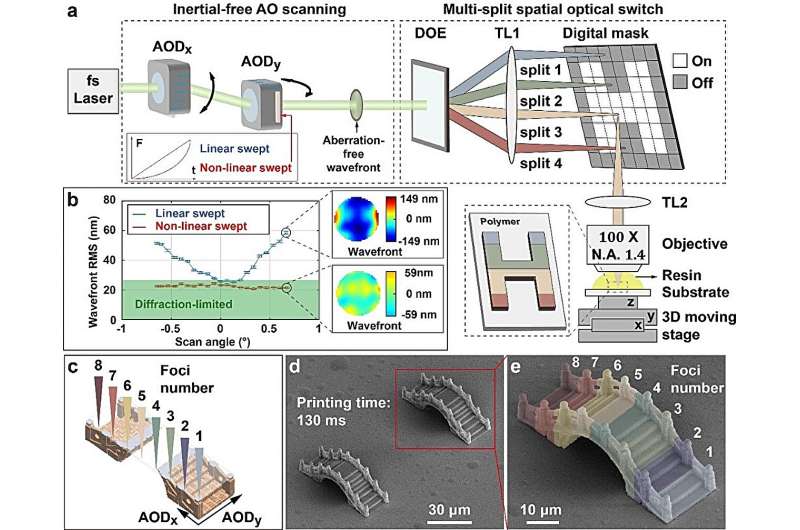

Conventional scanning-based TPL employs mechanical scanning strategies like galvanometric mirrors, however their scanning pace is constrained by inertia. In distinction, the acousto-optic deflector (AOD) can obtain inertial-free acousto-optic scanning, leading to a big development within the pace.

“The movement of a transferring automotive often consists of sequential actions comparable to braking, turning round, and subsequent acceleration which inherently consumes a considerable period of time because of the affect of inertia,” stated Binzhang Jiao (Ph.D. 22), the primary writer of the paper.

A galvanometer with inertia is rather like a automotive, the place acceleration and deceleration processes are time-consuming. Then again, AOD will not be constrained by inertia, as a result of it depends on sound waves for scanning. In comparison with conventional mechanical mirror scanning, this method has yielded a 5 to 20-fold improve in laser scanning pace.

Jiao has efficiently developed a nonlinear sign modulation strategy of the AOD, making certain the spot dimension approximates the diffraction restrict throughout high-speed acousto-optic scanning. Concurrently, the mixing of diffractive optical components (DOE) has enabled multi-focal parallel acousto-optic scanning, additional enhancing processing throughput. The spatial areas of the multi-focal spots are independently managed by the spatial optical change, enabling the fabrication of non-periodic buildings.

They demonstrated an eight-focal-point Multiphoton Lithography (MPL) system, attaining voxel dimension of 212 nm and the voxel printing fee of seven.6 × 107 voxel/s.

“A number of focal factors could be printed individually, as if one individual had eight fingers,” stated Jiao. This voxel printing fee is 8.4 instances sooner than the quickest mechanically scanned MPL technique reported previously, and 38 instances sooner than the quickest diffractive scanned MPL technique reported. When in comparison with commercialized MPL strategies, the printing pace of this method could be enhanced by as much as 490 instances.

Though it’s nonetheless an extended solution to go from labs to manufacturing facility, the crew expresses optimism about the way forward for AOSS. “To extend acousto-optic scanning vary, the scanning angle of the acousto-optic scanning could be elevated sooner or later. Accordingly, the next acousto-optic scanning pace and an elevated variety of foci can proceed to extend the throughput of AOSS,” stated Prof. Wei Xiong.

Extra data:

Binzhang Jiao Jiao et al, Acousto-optic Scanning Spatial-switching Multiphoton Lithography, Worldwide Journal of Excessive Manufacturing (2023). DOI: 10.1088/2631-7990/ace0a7

Supplied by

Worldwide Journal of Excessive Manufacturing

Quotation:

Report-high 3D printing fee reached by acousto-optical scanning (2023, October 10)

retrieved 10 October 2023

from https://phys.org/information/2023-10-record-high-3d-acousto-optical-scanning.html

This doc is topic to copyright. Aside from any truthful dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is offered for data functions solely.