Nov 09, 2023

(

Nanowerk Information) As local weather change and environmental considerations intensify, sustainable microbial cell factories garner vital consideration as candidates to switch chemical vegetation. To develop microorganisms for use within the microbial cell factories, it’s essential to switch their metabolic processes to induce environment friendly goal chemical manufacturing by modulating its gene expressions. But, the problem persists in figuring out which gene expressions to amplify and suppress, and the experimental verification of those modification targets is a time- and resource-intensive course of even for specialists.

The challenges had been addressed by a group of researchers at KAIST led by Distinguished Professor Sang Yup Lee and reported in

Cell Techniques (

“Genome-wide identification of overexpression and downregulation gene targets based mostly on the sum of covariances of the outgoing response fluxes”).

Key Takeaways

KAIST researchers develop a pc simulation, iBridge, to effectively construct microbial factories for chemical manufacturing.

iBridge predicts gene modification targets to boost microorganisms’ manufacturing of useful compounds.

The system streamlines the creation of E. coli strains able to producing industrial compounds like panthenol, putrescine, and 4-hydroxyphenyllactic acid.

The method outpaces conventional strategies, enabling the fast institution of various microbial cell factories.

This development may speed up the shift from chemical vegetation to sustainable microbial cell factories in response to local weather change.

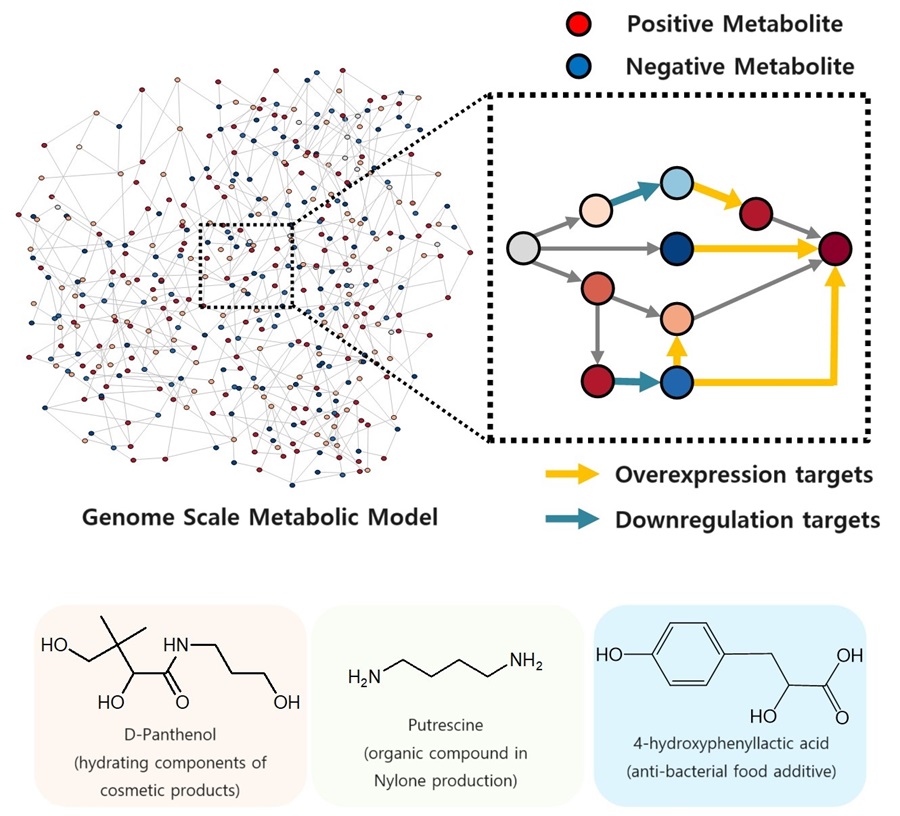

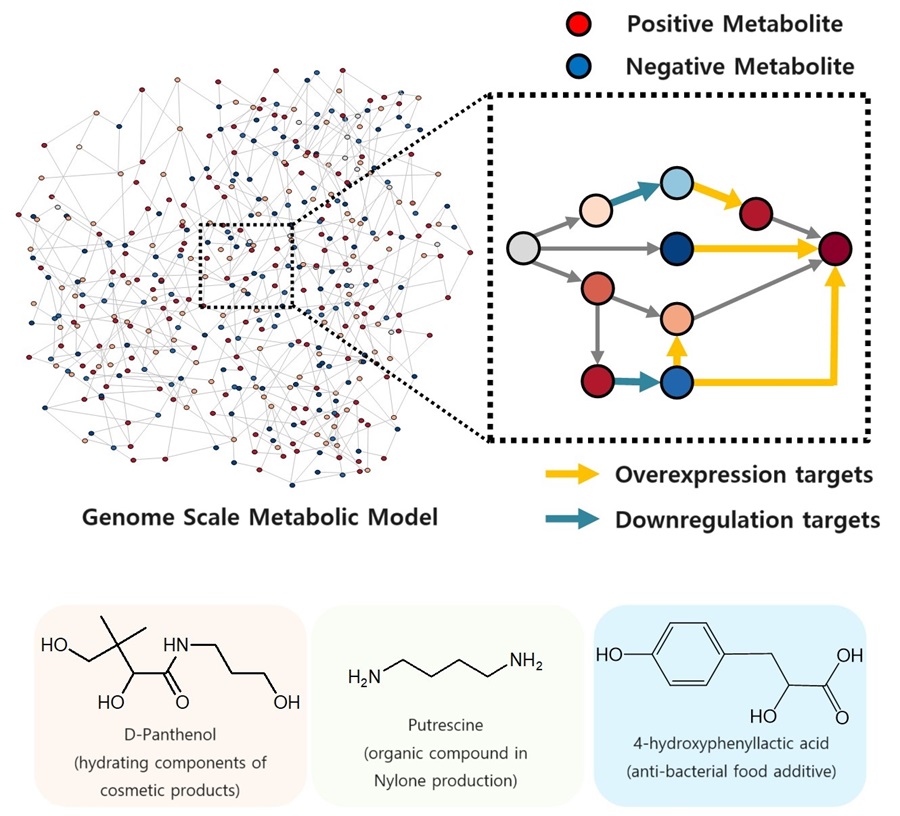

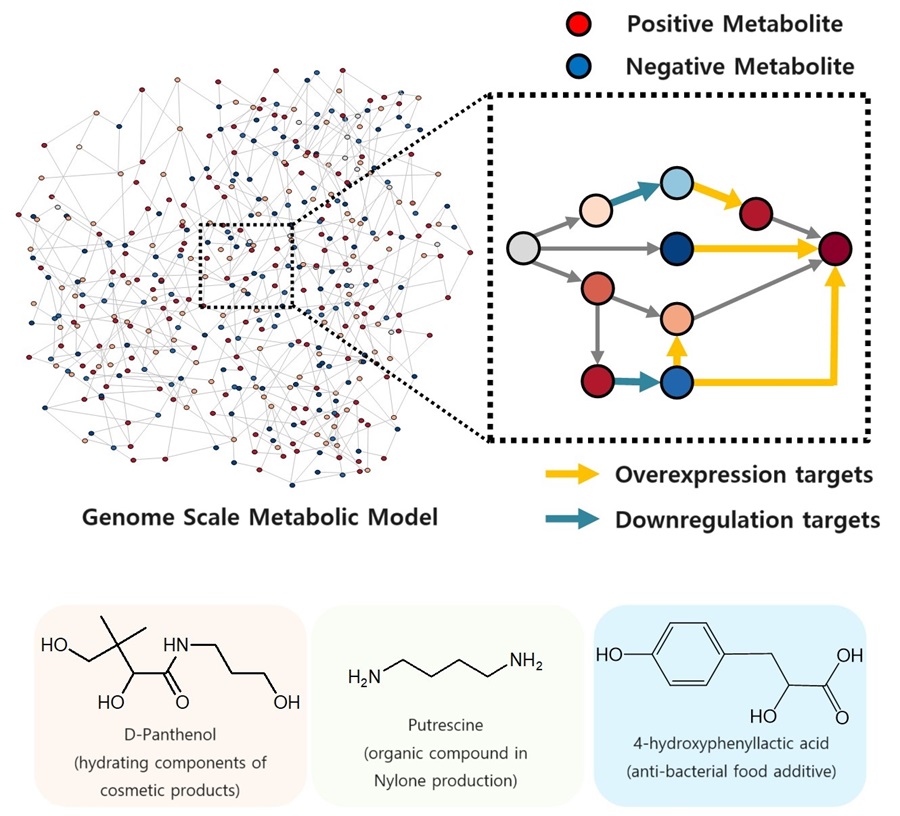

Conceptual diagram of the circulation of iBridge simulation. (Picture: KAIST)

The Analysis

It was introduced on the ninth by the college {that a} methodology for constructing a microbial manufacturing unit at low value, rapidly and effectively, was introduced by a novel pc simulation program developed by the group beneath Professor Lee’s steerage, which is known as “iBridge”. This progressive system is designed to foretell gene targets to both overexpress or downregulate within the aim of manufacturing a desired compound to allow the cost-effective and environment friendly development of microbial cell factories particularly tailor-made for producing the chemical compound in demand from renewable biomass.

Techniques metabolic engineering is a subject of analysis and engineering pioneered by KAIST’s Distinguished Professor Sang Yup Lee that seeks to supply useful compounds in industrial calls for utilizing microorganisms which might be re-configured by a mix of strategies together with, however not restricted to, metabolic engineering, artificial biology, methods biology, and fermentation engineering.

With the intention to enhance microorganisms’ functionality to supply helpful compounds, it’s important to delete, suppress, or overexpress microbial genes. Nonetheless, it’s troublesome even for the specialists to establish the gene targets to switch with out experimental confirmations for every of them, which may take up immeasurable period of time and assets.

The newly developed iBridge identifies constructive and damaging metabolites inside cells, which exert constructive and/or damaging affect on formation of the merchandise, by calculating the sum of covariances of their outgoing (consuming) response fluxes for a goal chemical. Subsequently, it pinpoints “bridge” reactions accountable for changing damaging metabolites into constructive ones as candidates for overexpression, whereas figuring out the opposites as targets for downregulation.

The analysis group efficiently utilized the iBridge simulation to ascertain E. coli microbial cell factories every able to producing three of the compounds which might be in excessive calls for at a manufacturing capability that has not been reported all over the world. They developed E. coli strains that may every produce panthenol, a moisturizing agent discovered in lots of cosmetics, putrescine, which is likely one of the key elements in nylon manufacturing, and 4-hydroxyphenyllactic acid, an anti-bacterial meals additive. Along with these three compounds, the research presents predictions for overexpression and suppression genes to assemble microbial factories for 298 different industrially useful compounds.

Dr. Youngjoon Lee, the co-first writer of this paper from KAIST, emphasised the accelerated development of assorted microbial factories the newly developed simulation enabled. He said, “With the usage of this simulation, a number of microbial cell factories have been established considerably quicker than it will have been utilizing the traditional strategies. Microbial cell factories producing a wider vary of useful compounds can now be constructed rapidly utilizing this expertise.”

Professor Sang Yup Lee stated, “Techniques metabolic engineering is an important expertise for addressing the present local weather change points.” He added, “This simulation may considerably expedite the transition from resorting to standard chemical factories to using environmentally pleasant microbial factories.”

Conceptual diagram of the circulation of iBridge simulation. (Picture: KAIST)

Conceptual diagram of the circulation of iBridge simulation. (Picture: KAIST)

Conceptual diagram of the circulation of iBridge simulation. (Picture: KAIST)

Conceptual diagram of the circulation of iBridge simulation. (Picture: KAIST)