Photoionisation detection (PID) sensors are in a position to detect potential issues earlier than they happen within the manufacture and use of lithium-ion (Li-ion) batteries, and the large number of gadgets that use rechargeable batteries.

The secure utilisation of Li-ion batteries is a key concern for the builders of kit equivalent to electrical autos, e-bikes, cellphones and laptops. The dangers posed by Li-ion batteries have been highlighted by a variety of high-profile incidents. In 2006 and 2007, for instance, hundreds of thousands of laptops and cellphones had been recalled resulting from security fears referring to their Li-ion batteries, and in 2013, a Boeing 787 was grounded following electrical points with the Li-ion battery within the plane’s auxiliary energy unit.

Famously, in 2016, round 2.5 million cellphones needed to be recalled after complaints of overheating and exploding batteries. Intensive investigations revealed inadequate insulation materials inside the batteries and a design that didn’t present adequate area to securely accommodate the batteries’ electrodes, leading to thermal runaway, which happens when temperatures are raised by thermal or mechanical failure, quick circuiting, or electrical abuse. In newer information, there was a 60% improve in e-bike fires in London in 2023 in comparison with 2022, and this quantity will proceed to rise. On account of the magnitude of this downside, and the worldwide publicity which ensues, demand is rising for sensing expertise that may detect defective Li-ion batteries, throughout each manufacturing and operation.

The principle security hazards related to failing Li-ion batteries are the ignition of the battery cell and/or the emissions of poisonous gases. These gases embrace unstable natural compounds (VOCs), that means delicate VOC sensors can be utilized to verify the situation of those batteries – both inside moveable detectors or in course of/plant monitoring tools.

The anode in rechargeable Li-ion batteries is often graphite, the cathode is a metallic ox-ide, and the electrolyte is often a lithium salt in a (flammable) natural solvent. This elec-trolyte contains compounds equivalent to ethyl methyl carbonate (EMC) which is understood to be among the many gases emitted by a defective Li-ion battery. Conveniently, EMC will be detected by ION Science’s PID, so the builders of monitoring techniques and tools are in a position to design applied sciences that utilise ION’s MiniPID sensors.

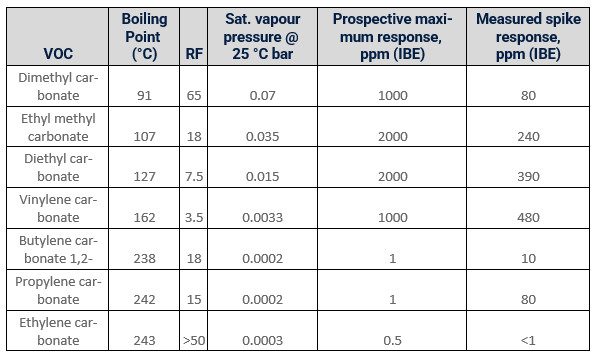

The Response Components for VOCs generally utilized in Li-ion battery electrolytes are pre-sented in Desk 1: Analysis of chemical substances utilized in lithium-ion batteries.

On account of their specificity, PID sensors are probably the most generally employed expertise for the detection of VOCs, and ION’s MiniPID vary contains probably the most delicate PID sensor on the planet, which makes it very best for the detection of hint leaks from defective Li-ion batteries.

Summarising, Peter Morris from ION Science says: “Potential clients for our PID sensors in Li-ion battery functions embrace the builders of moveable devices, in addition to the designers of monitoring techniques for processes inside battery manufacturing, in addition to within the manufacture of EVs, e-bikes, laptops, tablets, telephones and plenty of others.”

(phrases: ION Science)

References:

Nedjalkov, A.et Al. Poisonous Gasoline Emissions from Broken Lithium Ion Batteries—Evaluation and Security Enhancement Resolution. Batteries 2016, 2, 5. https://doi.org/10.3390/batteries2010005

https://information.samsung.com/international/infographic-galaxy-note7-what-we-discovered