A current undertaking blends leftover cooking oil, lamb fats and agricultural waste to develop a cleaner gas for ships.

The researchers – from Aston College – have blended blended waste pellets with both used oil or animal fats to develop a type of power which meets worldwide marine gas requirements.

At present most vessels run on an oil refinery waste product known as bunker gas, but it surely presents a number of environmental considerations together with the danger of oil spill and the emission of poisonous compounds and particulates. In 2020 the UN banned using heavy gas oil within the Arctic, following its ban in Antarctic waters in 2011.

Now scientists at Aston College have mixed waste materials provided by a Dutch anaerobic digestion plant with used oil or fats to create a mix which may very well be a alternative for bunker oil. Their analysis “Investigation of anaerobic digested pyrolysis oil and waste derived biodiesel blends as sustainable gas for marine engine software” has been printed within the journal Gasoline.

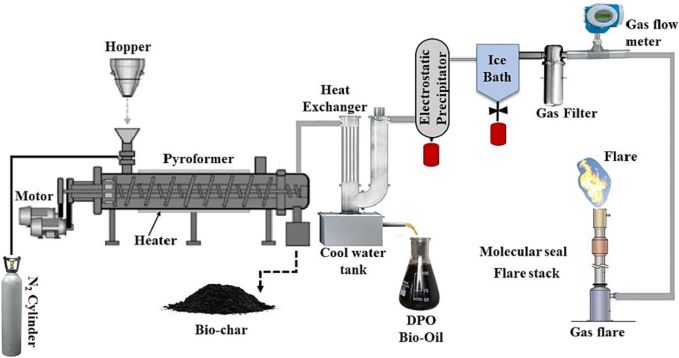

The waste pellets had been handled in Aston College’s pyrolysis-based reactor which heated them as much as 500 °C to transform them into bio-oil.

Solvents had been added to the bio-oil which was then blended with the used cooking oil or fats to create the gas.

Dr Abul Kalam Hossain, senior lecturer within the Division of Mechanical, Biomedical and Design Engineering, mentioned “Over the previous ten years each the quantity of marine transport and the corresponding greenhouse fuel emissions have elevated steadily.

“We knew of the potential of pyrolysis oils as renewable biofuels to be used at sea in diesel engines. Nevertheless, because of their low power content material, excessive acidity and viscosity we knew they wanted to be improved.”

The researchers created 5 blends including differing quantities of bio-oil, solvent and oil or fats and saved them at nighttime for eight months.

Checks confirmed the blends had improved their warmth worth, viscosity and density by round 25 to 40% and complied with Marine Gasoline Requirements (ISO 8216 and ISO 8217) to be used in diesel engines and boilers.

The paper states the oil blends can be utilized in stationary diesel engines in addition to marine diesel engines for energy era.

The analysis illustrates how biomass pyrolysis expertise has developed right into a sustainable approach which might flip meals and agricultural waste into bio-oil. The examine’s outcomes may finally contribute to higher international air high quality.

The Aston College analysis group labored alongside lecturers on the College of Structure, Expertise and Engineering College of Brighton, Indian Institute of Expertise Madras, India and the School of Engineering Guindy, Anna College, Chennai, India.

Investigation of anaerobic digested pyrolysis oil and waste derived biodiesel blends as sustainable gas for marine engine software – ScienceDirect