It takes chemist Liaisan Khasanova lower than a minute to show an peculiar silica glass tube right into a printing nozzle for a really particular 3D printer. The chemist inserts the capillary tube—which is only one millimeter thick—right into a blue gadget, closes the flap and presses a button. After a number of seconds there’s a loud bang and the nozzle is prepared to be used.

“A laser beam contained in the gadget heats up the tube and pulls it aside. Then we out of the blue enhance the tensile drive in order that the glass breaks within the center and a really sharp tip types,” explains Khasanova, who’s engaged on her Ph.D. in chemistry within the Electrochemical Nanotechnology Group on the College of Oldenburg, Germany.

Khasanova and her colleagues want the minuscule nozzles to print extremely tiny three-dimensional metallic buildings. This implies the nozzles’ openings should be equally tiny—in some instances so small that solely a single molecule can squeeze via. “We are attempting to take 3D printing to its technological limits,” says Dr. Dmitry Momotenko, who leads the junior analysis group on the Institute of Chemistry. His purpose: “We need to assemble objects atom by atom.”

Quite a few functions

Nanoscale 3D printing—in different phrases 3D printing of objects which might be a simply few billionths of a meter in measurement—opens up wonderful alternatives, the chemist explains. For metallic objects particularly, he can envisage quite a few functions in areas corresponding to microelectronics, nanorobotics, sensor and battery know-how: “Electroconductive supplies are wanted for every kind of functions in these areas, so metals are the proper resolution.”

Whereas 3D printing of plastics has already superior into these nanoscale dimensions, manufacturing tiny metallic objects utilizing 3D know-how has confirmed harder. With some strategies the printed buildings are nonetheless a thousand instances too massive for a lot of superior functions, whereas with others it’s inconceivable to manufacture the objects with the mandatory diploma of purity.

Momotenko focuses on electroplating, a department of electrochemistry the place metallic ions suspended in a salt resolution are introduced into contact with a negatively charged electrode. The positively charged ions mix with electrons to kind impartial metallic atoms that are deposited on the electrode, forming a strong layer.

“A liquid salt resolution turns into a strong metallic—a course of which we electrochemists can management very successfully,” says Momotenko. This identical course of is used for chrome-plating automotive elements and gold-plating jewellery on a bigger scale.

Somewhat smaller than ordinary

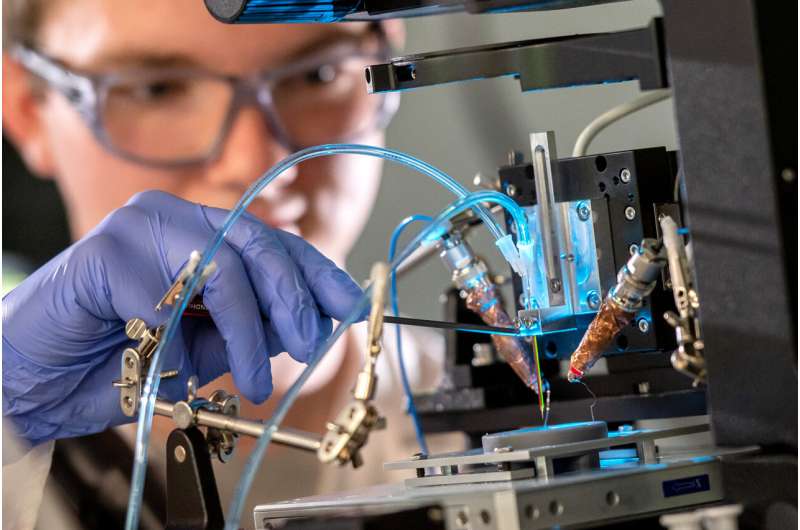

Nonetheless, transferring it to the nanoscopic scale requires appreciable ingenuity, effort and care, as a go to to the group’s small laboratory on the college’s Wechloy campus confirms. The lab incorporates three printers—all constructed and programmed by the group itself, as Momotenko factors out. Like different 3D printers they include a print nozzle, tubes for feeding within the print materials, a management mechanism and the mechanical elements for transferring the nozzle—however in these printers every little thing is a bit smaller than ordinary.

A coloured saline resolution flows via delicate tubes into the skinny capillary tube, which in flip incorporates a hair-thin piece of wire—the anode. It closes the circuit with the negatively polarized cathode, a gold-plated silicon flake smaller than a fingernail, which can also be the floor on which the printing takes place. Micromotors and particular crystals that morph instantaneously when {an electrical} voltage is utilized quickly transfer the nozzle by fractions of a millimeter in all three spatial instructions.

Since even the slightest vibrations can disrupt the printing course of, two of the printers are housed in containers coated in a thick layer of dark-colored acoustic foam. Moreover, they’re resting on granite plates, every weighing 150 kilograms. Each measures are aimed toward stopping undesirable vibrations. The lamps within the lab are additionally battery-powered as a result of the electromagnetic fields produced by alternating present from a socket would intervene with the tiny electrical currents and voltages wanted to manage the nanoprinting course of.

A visit into the nanoworld

In the meantime, Liaisan Khasanova has ready every little thing for a check print: the print nozzle is in its beginning place, the field is closed, a vial containing a lightweight blue copper resolution is related to the tubes. She begins a program which initiates the printing course of. Measurement information seems on a display as curves and dots. These present the variations within the present circulate and register the nozzle briefly touching the substrate after which retracting many times. What’s the machine printing? “Only a few columns,” she replies.

Columns are the best geometric types generated in 3D printing, however the Oldenburg researchers may print spirals, rings and every kind of overhanging buildings. The method can at present be used to print with copper, silver and nickel, in addition to nickel-manganese and nickel-cobalt alloys. In a few of their experiments, they’ve already ventured deep into the nanoworld. Momotenko and a world group of researchers reported in a research revealed within the journal Nano Letters in 2021 that they’d produced copper columns with a diameter of simply 25 nanometers—taking 3D metallic printing under the 100-nanometer restrict for the primary time.

One of many cornerstones for this success was a suggestions mechanism that permits precision management of the print nozzle’s actions. It was developed by Momotenko along with Julian Hengsteler, a Ph.D. scholar he supervised at his earlier place of business, ETH Zurich in Switzerland. “The continual retraction of the print nozzle is enormously vital, as a result of in any other case it will shortly grow to be clogged,” explains the chemist.

“A liquid salt resolution turns into a strong metallic—a course of which we electro-chemists can management very successfully.”

The group prints the tiny objects layer by layer at speeds of some nanometers per second. Momotenko nonetheless finds it wonderful that objects too small to be seen to the human eye are being created right here. “You begin with an object you’ll be able to contact. Then a sure transformation takes place and you’ll be able to management these invisible issues at a particularly small scale—it’s nearly unbelievable,” says the chemist.

An e-car could be charged inside seconds

Momotenko’s plans for his nanoprinting method are additionally fairly mind-boggling: his purpose is to put the foundations for batteries that may be charged a thousand instances quicker than present fashions. “If that may be achieved, you can cost an e-car inside seconds,” he explains. The fundamental thought he’s pursuing is already round 20 years previous. The precept is to drastically shorten the pathways of the ions contained in the battery throughout the charging course of.

To do that, the electrodes, that are at present flat, must have a three-dimensional floor construction. “With the present battery design, charging takes so lengthy as a result of the electrodes are comparatively thick and much aside,” Momotenko explains.

The answer, he says, is to interlock the anodes and cathodes like fingers on the nanoscale and cut back the gap between them to just some nanometers. This is able to enable the ions to maneuver between anode and cathode at lightning velocity. The issue: up to now it has not been potential to provide battery buildings with the required nano dimensions.

Momotenko has now taken on this problem. In his NANO-3D-LION undertaking, the place the purpose is to develop and make use of superior nanoscale 3D printing strategies to manufacture lively battery supplies with ultrasmall structural options. Having collaborated efficiently with a analysis group led by Prof. Dr. Gunther Wittstock on the Institute of Chemistry in an earlier undertaking, Momotenko then determined to base the undertaking on the College of Oldenburg. “The Division for Analysis and Switch was very useful with my grant utility, so I moved right here from Zurich at first of 2021,” he explains.

His analysis group now has 4 members: apart from Khasanova, Ph.D. scholar Karuna Kanes and Grasp’s scholar Simon Sprengel have joined the group. Kanes focuses on a brand new technique aimed toward optimizing the precision of the print nozzle, whereas Sprengel investigates the potential for printing combos of two totally different metals—a course of vital to provide cathode and anode materials concurrently in a single step.

Liaisan Khasanova will quickly concentrate on lithium compounds. Her mission can be to learn how the electrode supplies at present utilized in lithium batteries may be structured utilizing 3D printing. The group is planning to research compounds corresponding to lithium-iron or lithium-tin, after which to check how massive the nano “fingers” on the electrode surfaces must be, what spacing is possible, and the way the electrodes needs to be aligned.

Dealing with highy reactive lithium

One main hurdle right here is that lithium compounds are extremely reactive and may solely be dealt with beneath managed situations. For that reason, the group lately acquired an extra-large model of a laboratory glove field, a gas-tight sealed chamber that may be full of an inert gasoline corresponding to argon. It has dealing with gloves constructed into one aspect with which the researchers can manipulate the objects inside.

The chamber, which is about three meters lengthy and weighs half a ton, will not be but in operation, however the group plans to arrange one other printer inside it. “The chemical conversion of the fabric and all different assessments may even need to be carried out contained in the chamber,” Momotenko explains.

The group will run up in opposition to some main questions in the middle of the undertaking: How do tiny impurities throughout the argon environment have an effect on the printed lithium nanostructures? Methods to dissipate the warmth that’s inevitably generated when batteries are charged inside seconds? Methods to print not simply tiny battery cells but additionally massive batteries for powering a cell phone or perhaps a automotive—inside an inexpensive time?

“On the one hand, we’re engaged on the chemistry wanted to provide lively electrode supplies on the nanoscale; on the opposite, we are attempting to adapt the printing know-how to those supplies,” says Momotenko, outlining the present challenges.

The issue of power storage is extraordinarily complicated, and his group can solely play a small half in fixing it, the researcher emphasizes. Nonetheless, he sees his group in a superb beginning place: in his opinion, electrochemical 3D printing of metals is at present the one viable possibility for manufacturing nanostructured electrodes and testing the idea.

Along with battery know-how, the chemist can also be engaged on different daring ideas. He needs to make use of his printing method to provide metallic buildings that enable for a extra focused management of chemical reactions than potential up to now. Such plans play a task in a comparatively younger discipline of analysis referred to as spintronics, which focuses on the manipulation of “spin”—a quantum mechanical property of electrons.

One other thought he hopes to place into observe is to fabricate sensors which might be capable of detect particular person molecules. “That might be useful in drugs, for detecting tumor markers or biomarkers for Alzheimer’s at extraordinarily low concentrations, for instance,” says Momotenko.

All these concepts are nonetheless very new approaches in chemistry. “It’s not but clear how it will all work,” he admits. However that is how it’s in science: “Each significant analysis undertaking requires lengthy considering and planning, and in the long run most concepts fail,” he concludes. However typically they do not—and he and his group have already taken the primary profitable steps on their journey.

Offered by

College of Oldenburg

Quotation:

Printing atom by atom: Lab explores nanoscale 3D printing (2022, December 16)

retrieved 16 December 2022

from https://phys.org/information/2022-12-atom-lab-explores-nanoscale-3d.html

This doc is topic to copyright. Aside from any honest dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for info functions solely.