A imaginative and prescient for future processors with practically double the density of transistors is starting to take form, now that each one three superior chipmakers have demonstrated CFETS, or complementary field-effect transistors. CFETs are a single construction that stacks each the kinds of transistors wanted for CMOS logic. On the IEEE Worldwide Electron Units Assembly this week in San Francisco, Intel, Samsung, and TSMC confirmed what progress they’ve made towards the following evolution in transistors.

Chip corporations are transitioning from the FinFET system construction in use since 2011 to nanosheet, or gate-all-around, transistors. The names replicate the essential construction of the transistor. Within the FinFET, the gate controls the circulation of present by way of a vertical silicon fin. Within the nanosheet system, that fin is minimize right into a set of ribbons, every of which is surrounded by the gate. The CFET basically takes a taller stack of ribbons and makes use of half for one system and half for the opposite. This system, as Intel engineers defined within the December 2022 difficulty of IEEE Spectrum, builds the 2 kinds of transistor—nFETs and pFETs—on prime of one another in a single, built-in course of.

Specialists estimate CFETs to roll out commercially seven to 10 years from now, however there’s nonetheless loads of work earlier than they’re prepared.

Intel’s inverter

Intel was earliest of the three to display the CFET, unveiling an early model at IEDM again in 2020. This time round, Intel is reporting a number of enhancements surrounding the best circuit that the CFET makes, an inverter. A CMOS inverter sends the identical enter voltage to the gates of each gadgets within the stack and produces an output that’s the logical inverse of the enter.

“The inverter is finished on a single fin,” Marko Radosavljevic, principal engineer at Intel’s parts analysis group, informed reporters forward of the convention. “At most scaling, it might be 50 p.c” of the dimensions of an strange CMOS inverter, he mentioned.

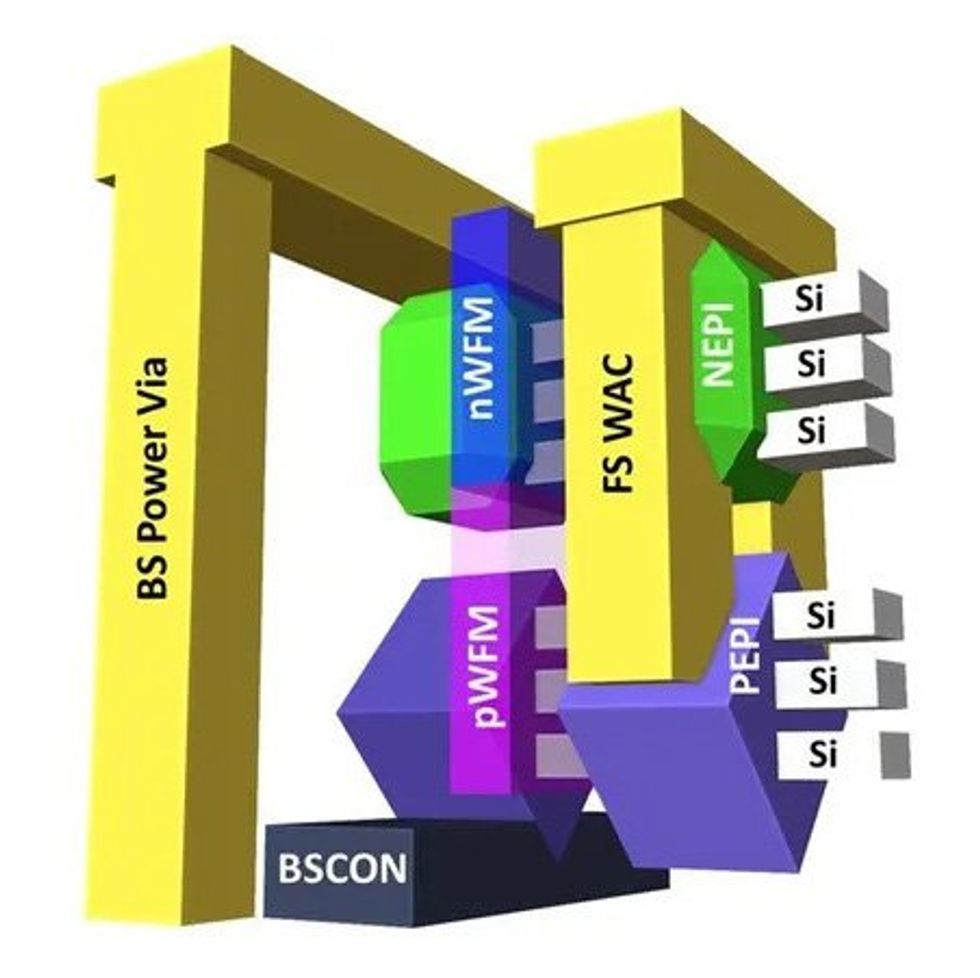

Intel’s inverter circuits rely on a brand new means of connecting the highest and backside transistors [yellow] and on contacting one in all them from beneath the silicon [grey]Intel

Intel’s inverter circuits rely on a brand new means of connecting the highest and backside transistors [yellow] and on contacting one in all them from beneath the silicon [grey]Intel

The hitch is that squeezing in all of the interconnects wanted to make that two-transistor stack into an inverter circuit eats away on the space benefit. To maintain issues tight, Intel tried to take away a few of the congestion concerned in connecting to the stacked system. In at the moment’s transistors, all of the connections come from above the system itself. However later this yr, Intel is deploying a know-how known as bottom energy supply that permits interconnects to exist each above and under the floor of the silicon. Utilizing that know-how to contact the underside transistor from under as a substitute of from above considerably simplified the circuit. The ensuing inverter had a density high quality known as contacted poly pitch (CPP, basically the minimal distance from one transistor gate to the following) of 60 nanometers. As we speak’s 5 nm node chips have a CPP of about 50 nm.

Moreover, Intel improved the CFET stack’s electrical traits by growing the variety of nanosheets per system from two to 3, reducing the separation between the 2 gadgets from 50 nm to 30 nm, and utilizing an improved geometry for connecting components of the system.

Samsung’s secret sauce

Samsung went even smaller than Intel, exhibiting outcomes for 48-nm and 45-nm contacted poly pitch (CPP), in comparison with Intel’s 60 nm, although these have been for particular person gadgets, not full inverters. Though there was some efficiency degradation within the smaller of Samsung’s two prototype CFETs, it wasn’t a lot, and the corporate’s researchers imagine manufacturing course of optimization will deal with it.

Essential to Samsung’s success was the power to electrically isolate the sources and drains of the stacked pFET and nFET gadgets. With out satisfactory isolation, the system, which Samsung calls a 3D stacked FET (3DSFET), will leak present. A key step to reaching that isolation was swapping an etching step involving moist chemical compounds with a brand new sort of dry etch. That led to an 80 p.c enhance within the yield of excellent gadgets.

Like Intel, Samsung contacted the underside of the system from beneath the silicon to avoid wasting house. Nonetheless, the Korean chipmaker differed from the American one by utilizing a single nanosheet in every of the paired gadgets, as a substitute of Intel’s three. In line with its researchers, growing the variety of nanosheets will improve the CFET’s efficiency.

TSMC takes its shot

Like Samsung, TSMC too managed to get to an industrially-relevant pitch of 48 nm. Its system’s distinctions included a brand new strategy to type a dielectric layer between the highest and backside gadgets to maintain them remoted. Nanosheets are usually fashioned from alternating layers of silicon and silicon germanium. On the acceptable step within the course of, a silicon-germanium particular etching technique removes that materials, releasing the silicon nanowires. For the layer destined to isolate the 2 system from one another, TSMC used silicon germanium with an unusually excessive fraction of germanium, realizing that it might etch away quicker than the opposite SiGe layers. That means the isolation layer could possibly be constructed a number of steps earlier than releasing the silicon nanowires.

From Your Website Articles

Associated Articles Across the Internet