The IoT helps firms cut back, reuse, and transfer the needle towards circularity.

In September, Patagonia founder Yvon Chouinard set a excessive bar for firms that declare to care concerning the planet. Chouinard and his heirs primarily gave the out of doors clothes and equipment firm away for the good thing about the surroundings. And whereas this enterprise transfer represents what many past the Chouinard household contemplate to be an excessive dedication to the planet, committing assets to the pursuit of sustainability and a extra round enterprise mannequin has grow to be far much less excessive of a place than it was once.

A majority of companies in Deloitte’s 2022 CxO Sustainability Report self-reported constructive steps towards sustainability and round targets. As an example, the report says 67% of organizations are utilizing extra sustainable supplies of their companies, 66% are growing their power effectivity, 57% are utilizing energy-efficient or climate-friendly equipment, applied sciences, and tools, and 57% are coaching workers on local weather change actions and impacts. By way of among the harder-to-implement, needle-moving actions, Deloitte’s report suggests fewer firms are presently collaborating, however good progress is being made, nonetheless. For instance, 49% are growing new climate-friendly services or products, 46% are requiring suppliers and enterprise companions to satisfy particular sustainability standards, and 37% are tying senior leaders’ compensation to environmental sustainability efficiency.

Kevin Hsu, vice chairman of innovation at Sterling Options, says the way in which companies are approaching environmental stewardship is altering for the higher. “The notion that you just couldn’t compete economically and be environmentally accountable has been challenged efficiently in so many areas, and that mindset is driving innovation,” Hsu says. “I feel individuals are beginning to get quite a bit smarter about how we view the world. It’s grow to be extra clear that our long-term future relies on bringing extra circularity into our financial pondering.”

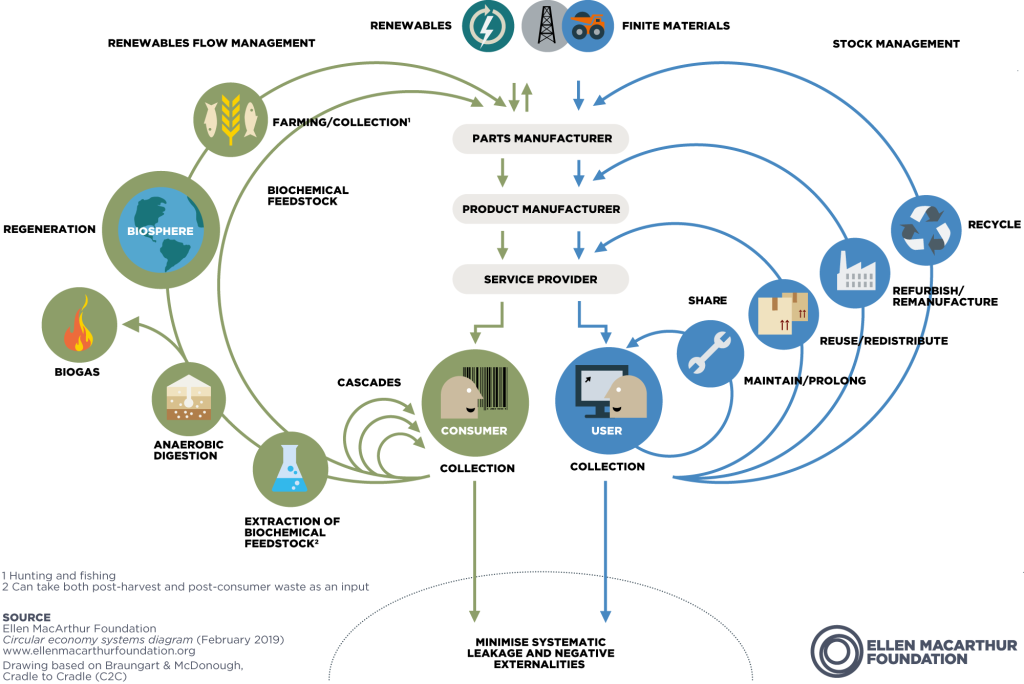

Round pondering, together with the concept that a enterprise will be environmentally accountable and aggressive, plus the truth that sustainable targets are driving enterprise innovation are all including up and contributing to a bigger-picture motion. Large information and the IoT (Web of Issues) applied sciences are two of the forces enabling this motion—a motion during which companies, governments, and people are working collectively greater than ever earlier than to grow to be higher stewards of the planet’s assets.

Sensible Manufacturing, Sensible Enterprise

In manufacturing, IoT applied sciences are serving to companies improve precision and effectivity, which may help cut back waste. Jacqueline Cramer, professor at Utrecht College within the Netherlands, says extra refined design strategies assist guarantee society produces what it wants—no extra, no much less. “Once you design extra exactly by means of all of the strategies we now have now, then there’s not that a lot left over,” Cramer explains. “And what is left over you may as well carry again into design, and you’ll reuse that in your course of so then there isn’t any waste left—or not less than a lot much less.”

Buckley Brinkman, govt director and CEO of the Wisconsin Heart for Manufacturing and Productiveness, says one of the best options cut back useful resource consumption whereas additionally growing output, and this simply makes good enterprise sense. “Only a few producers pursue sustainability or a round economic system purely to save lots of the world,” Brinkman says, mentioning Yvon Chouinard and Patagonia for instance of an organization that breaks this mildew. “Many of the producers we assist pursue sustainability as a result of it may be good enterprise—making their operations extra environment friendly and decreasing their prices.”

Producers typically undertake superior expertise instruments to enhance productiveness, flexibility, and responsiveness. Sensible manufacturing can even result in much less waste, however not by default. “Sensible manufacturing results in much less waste when firms implement the right expertise within the correct means with the right involvement of the individuals who will run it,” Brinkman says. “Too typically, we see producers leap at new expertise earlier than they perceive the place it could have probably the most impression. Historically, we used worth stream maps and stream analyses to establish key locations to use expertise in a measured means with one of the best outcomes. Now, the power to create a digital twin—a pc mannequin—permits operations to see how specific adjustments will impression their operations earlier than making giant investments or hard-to-reverse selections. This protects time, cash, and wasted effort.”

5 Methods Expertise Can Enhance Sustainability

Josué Velázquez Martínez, director of the Sustainable Provide Chain Lab at MIT (Massachusetts Institute of Expertise), lists 5 methods expertise can enhance sustainability:

- Visibility: By having in place programs that may maintain monitor of the operations (manufacturing, transportation, and so on.) within the provide chain from extraction to consumption, it’s attainable to establish and mitigate environmental and social scorching spots.

- Effectivity: Methods like automation allow firms to function with excessive ranges of productiveness, making the requirement of power decrease than semi-manual operations, thereby decreasing carbon emissions.

- Connectivity (particularly associated to 5G or broadband): These applied sciences allow connectivity between customers to construct realtime synchronized options, which improves power utilization and higher planning, plus reduces environmental impacts general.

- Monitoring: Utilizing expertise, it’s attainable to offer realtime indicators associated to the sustainability efficiency (e.g., carbon emissions, power utilization, and so on.). These indicators will be outlined in each strategic and operational ranges.

- Operations: Applied sciences enable for the usage of machine studying and information analytics in a wide range of provide chain processes (demand planning, stock, transportation, and so on.). That is primarily attainable because of expertise development and pc energy.

Debbie Shakespeare, senior director of compliance, sustainability, and core product traces at Avery Dennison RBIS, says good manufacturing not solely results in much less waste but in addition creates constructive ripple results all through the complete provide chain. “In addition to utilizing digital instruments to advertise round consumption, good manufacturing and digital innovation can drive provide chain effectivity and reduce waste,” she says. “RFID expertise and digital product monitoring may help an organization keep away from over-manufacturing. As an alternative, an organization solely makes what’s required, so much less waste is produced and, in consequence, (there’s) a discount within the provide chain’s general carbon footprint. Companies are actually making use of this to a larger extent, though extra effort remains to be required.”

Shakespeare says information is enabling the digital transformations that trend companies and retailers are more and more making a precedence. She additionally factors out that in an age of greenwashing, manufacturers want actual information to substantiate the methods they’re addressing environmental challenges. “We’ll want factors of connectivity on clothes to seize and monitor the information wanted for sustainability, circularity, and digital buyer involvement,” she says. “Solely then can trend legitimately declare to be environmentally pleasant.”

Advances in expertise and good manufacturing are reshaping enterprise at Avery Dennison and past, delivering value and effectivity financial savings. “Leveraging information and good manufacturing is crucial to our success in delivering to our prospects,” Shakespeare provides. “Sensible manufacturing is all about connecting processes digitally with different networks, enabling machines to automate and produce independently and ultra-efficiently. Our goal is to make duties extra environment friendly and efficient, leveraging information to drive higher decisionmaking. Whether or not that’s within the manufacturing of bodily items, high quality checks, or communication with our downstream suppliers, it’s the connectivity that counts.”

Shifting Towards Circularity

There isn’t any doubt expertise and information present transparency inside provide chains and are the important thing to extra sustainable and round programs. Within the attire business, Shakespeare says digitalized or “related” clothes may help meet the growing want and need for sustainability by offering entry to huge quantities of knowledge.

“To get rid of garment waste, the business wants composition and manufacturing course of information about each merchandise, in addition to the power to hyperlink info right through the availability chain,” she explains. “The journey to trend circularity might really progress as soon as that is extensively out there and recycling amenities have been appropriately supported and ramped up. Reverse logistics companions can automate the sorting course of by scanning a digital set off, equivalent to a QR code, on a garment to entry constant information, whatever the model. This can velocity up the method of figuring out if a garment will be resold or what kind of recycler is required to deal with its elements. Resellers will be capable of use the identical applied sciences to confirm the authenticity of merchandise.”

On the identical time, digital labels additionally enable customers to study concerning the historical past and composition of clothes, in addition to how and the place to recycle them. “For the retailer, digital expertise will present actual post-purchase monitoring of a garment, permitting it to be acquired as soon as a buyer has completed with it and repurposed in a wide range of methods,” Shakespeare concludes. “Manufacturers can monitor the quantities of stock shifting again into the round economic system and assess how successfully they’re decreasing their carbon footprint—all by means of utilizing QR codes on clever care labels. Having a everlasting digital set off, like a QR code, unlocks the power to propel the complete enterprise ahead by offering information that can promote essential consciousness and permit for brand spanking new strategies of working.”

Every sector is shifting towards circularity and leveraging expertise to do extra with much less at a special tempo. At Sterling Options, a wooden merchandise producer, Hsu says wooden merchandise are extremely “round” by their very nature. He sees round pondering impacting how the constructing and development industries resolve issues. In his business, Hsu explains how expertise improves manufacturing effectivity—the amount of lumber that may be produced from a set quantity of logs—and has allowed for the appearance of recent merchandise like plywood and CLT (cross-laminated timber), which is Sterling’s main product.

“Add to that the developments we’ve seen in fabrication tools, together with developments in constructing design, equivalent to computer-aided design software program, and all of a sudden we’re leveraging a pure useful resource—wooden—in an entire new means,” Hsu says. “What we’ve skilled within the wooden merchandise business is expertise that not solely helps us be extra environment friendly with the useful resource, however finally leads us to viewing the useful resource otherwise and imagining how we’d put it to use in solely new methods—ways in which may have far-reaching results on our planet’s capability to maintain life as we all know it.”

Pure Useful resource Stewardship

Dean Amhaus, president and CEO of the The Water Council, says the IoT can contribute to round economic system targets by offering important information parts wanted to optimize an entire course of, predicting demand and stock wants and enhancing power use, tools upkeep, and the usage of uncooked supplies in a means that enhances decisionmaking and minimizes waste. “When producers glean insights from previous and present manufacturing information, they will higher handle their inputs and uncooked supplies and might handle their provide chain, resulting in decreasing extra stock,” Amhaus says. “Contemplating ongoing provide chain crimps, shortages, and lengthy lead instances, that is harder.”

Expertise performs a central position in serving to society steward water assets, offering the precise information, info, connectivity, and pattern traces to tell built-in water useful resource administration. “When mixed with water stewardship, expertise deployed strategically ought to assist us tackle and resolve lots of our most urgent shared-water challenges,” Amhaus provides. “For probably the most half, we now have the precise expertise and know-how, now we have to muster the collective will energy and funding to do the arduous work of investing in and constructing extra resilient water programs.”

As an example, Amhaus says it’s recognized how most of the U.S.’s most necessary aquifers are careworn, but these groundwater sources provide a lot of the nation’s agricultural manufacturing. IoT applied sciences enable farmers and others to actively monitor nicely depth, apply irrigation at focused spots, and monitor water high quality from the palm of their palms. “We’re additionally confronted with new challenges like PFAS (perfluoroalkyl and polyfluoroalkyl substances) contamination,” Amhaus says. “Emergent applied sciences are presently being developed to assist us break down and take away from the surroundings these so-called ‘ceaselessly’ chemical substances.”

Expertise additionally makes it attainable to remotely monitor and management water utilities. In actual fact, through the top of the pandemic, Amhaus says many crucial capabilities of municipal water programs have been remotely managed. “Taken as an entire, we now have the technological functionality to sustainably work together with all features of the water cycle on this planet,” he stresses. “It comes all the way down to collective will energy and funding to deploy these applied sciences to deal with our shared-water challenges. A few of the extra sophisticated and impactful options will take time, creativity, capital, and robust management.”

The Wisconsin Heart for Manufacturing and Productiveness’s Brinkman says progress towards sustainability and circularity will transfer quickest in sectors the place initiatives generate a constructive—or not less than a impartial—fee of return. “We discover firms will pursue sustainability initiatives with a strong financial justification,” he says. “They may also pursue initiatives that lowers threat publicity. For instance, certainly one of our producers put in a large photo voltaic panel array to decrease their threat of energy interruption and publicity to cost will increase.”

One firm doing its half is nice, but it surely’s going to take a coordinated effort from not only one firm, one sector, or one nation however an entire bunch of firms, sectors, and international locations to totally notice a round economic system—one which prioritizes decreasing, reusing, and maximizing effectivity. The answer goes past only one expertise or set of applied sciences, as nicely. Utrecht College’s Cramer says in shifting to a extra round economic system, applied sciences are essential, however they’re only one piece of the puzzle. “Once we transfer to a round economic system, it’s a system innovation and never only a technological innovation of 1 firm or one expertise,” she explains. “It’s a system change during which all events which can be related ought to take part.”

As a result of circularity is a system change, expertise adoption is essential, but it surely’s not the one requirement. “You additionally must take care of the non-technical points—the organizational change that must be made, the behavioral adjustments, the monetary and financial adjustments, and the regulatory adjustments,” Cramer concludes. “A transfer to circularity is an general change that may help expertise, however we will’t make the change with expertise alone.”

Hyperlinks For Additional Studying:

Need to tweet about this text? Use hashtags #IoT #sustainability #AI #5G #cloud #edge #digitaltransformation #machinelearning #bigdata #AveryDennison #Patagonia #TheWaterCouncil #circularity #circulareconomy#stewardship #naturalresources #power #retail #trend #SterlingSolutions #development#constructing #supplychain