Since 2020, a slew of disruptions has obstructed the sleek operations of firms world wide, making it troublesome for a lot of to acquire the elements they want or get their merchandise to clients. With vital financial uncertainty more likely to proceed within the foreseeable future, enterprise leaders could be sensible to arrange their firms to adapt extra shortly and holistically to altering circumstances.

Based mostly on my intensive expertise as a enterprise planning and enterprise operations guide, I consider that one of the best ways to do that is thru gross sales and operations planning (S&OP). There are other ways to implement this collaborative methodology, however all of them assist firms develop a complete long-term plan (12 to 18 months) that features and aligns particular targets for each the industrial divisions (product, gross sales, and customer support) and operations. I normally advocate additionally together with finance (monetary planning, budgeting, and value administration) and international technique divisions when implementing S&OP, a way typically often called built-in enterprise planning (IBP).

S&OP is an iterative course of, so it usually incorporates new enter from stakeholders, enabling an organization to reply quickly to altering environments. And one of many chief advantages of my method is that it may well sync provide with consumer demand, whereas concurrently matching each day operations to enterprise targets.

Corporations that regularly use new info to adapt can spot oncoming issues earlier than they hit. For instance, S&OP can alert corporations that they could must establish different producers, distributors, or distributors to make use of when their common companions can’t ship merchandise. Just a few years in the past, I used to be working with an auto elements firm in Ecuador that purchased merchandise to distribute to clients. We began having issues getting the elements from our distributors, which have been based mostly in China. However in the middle of S&OP work, we had already researched backup distributors and located a elements distributor in Dubai. When obstacles appeared, we pivoted swiftly to get the merchandise from this new supply and minimized any influence on our clients.

Analysis means that our expertise was not distinctive. In line with assessments of greater than 170 firms by McKinsey & Firm, organizations with a well-functioning IBP implementation have “service ranges which can be 5 to twenty proportion factors increased, freight prices and capital depth (whole property divided by gross sales) which can be 10% to fifteen% decrease, and buyer supply penalties and missed gross sales which can be 40% to 50% decrease” than these of firms with out efficient IBP. Companies which have optimized IBP processes are 10% to twenty% extra productive than corporations with out them, and so they reply to disruptive occasions shortly and successfully.

Whereas S&OP shouldn’t be a brand new course of, the provide chain disaster has made it clear that too few firms are benefiting from it, both as a result of they don’t have the suitable processes in place, or they aren’t utilizing them to greatest impact. On this article, I share my insights about methods to provoke or enhance S&OP implementation so your organization can climate provide chain issues and different potential disruptions, like freight or cargo container limitations, pure disasters, or IT outages.

Why S&OP Optimization Is So Vital Now

I used to be launched to S&OP greater than twenty years in the past whereas establishing a manufacturing useful resource planning course of for a cosmetics producer. Again then, S&OP was a useful option to keep alignment on firm objectives and to extend productiveness and cut back waste when particular issues arose that have been exceptions to the norm. As we speak, within the aftermath of a generalized international provide chain disaster, S&OP has develop into a necessity for companies that depend on a number of provide chain processes.

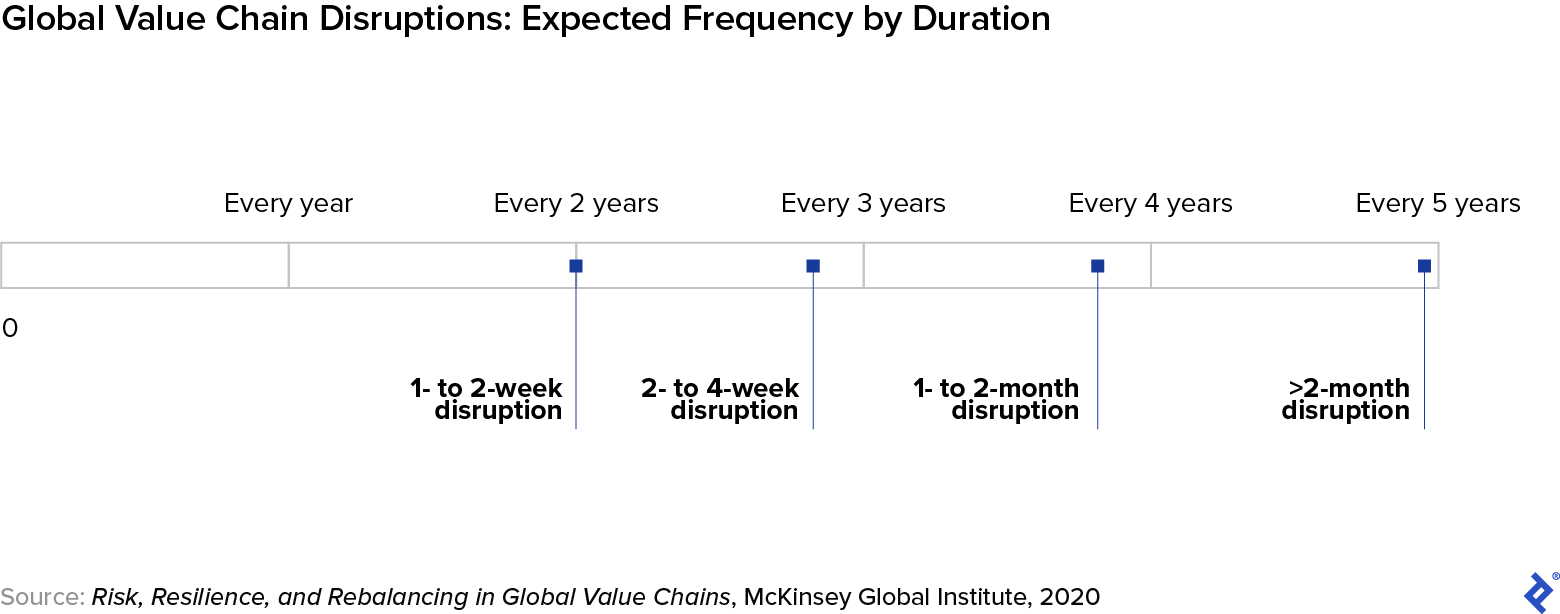

By now, the worldwide provide chain disruptions brought on by the COVID-19 pandemic, the Russia-Ukraine battle, skyrocketing freight transport costs, restricted transport container provide, and different components have principally subsided. Nonetheless, there are all the time unknowns on the horizon. A McKinsey World Institute report discovered that firms ought to “count on provide chain disruptions lasting a month or longer to happen each 3.7 years” and that the gathered losses of those occasions might signify 42% of 1 yr’s revenue over a 10-year interval.

As we speak’s lengthy, complicated provide chains are extremely susceptible to disruptions, together with excessive climate occasions, terrorism, or commerce disputes. That’s why S&OP is so very important. The truth is, enhancing S&OP is the highest precedence for chief provide officers, in response to a 2020 survey by The Hackett Group, and continues to be a key point of interest for optimization. This concern is a tacit acknowledgement that merely placing a course of in place isn’t sufficient. Poorly executed S&OP also can intervene with a corporation’s means to enlist alternate producers, distributors, and distributors; establish different clients; or typically handle its market and demand.

Corporations have all the time been involved about sudden occasions that would make it troublesome for them to get the supplies they want, produce sufficient to fulfill demand, or get their merchandise to their clients. However for in the present day’s hyperproductive companies, usually counting on a extremely fragile international worth chain, the stakes are increased than ever earlier than.

How the S&OP Course of Works

First, let’s look at how S&OP is designed to perform. It’s a extremely collaborative course of that includes enter from each division at each stage. Preliminary implementation begins with the formation of a cross-functional S&OP group that works to coordinate and finalize plans at every stage. Whereas your group’s actual composition will fluctuate based mostly in your firm’s measurement and make-up, with the IBP method, it normally consists of individuals from the next departments:

- Industrial: product, gross sales, and customer support managers, demand supervisor, and demand planners

- Operations: manufacturing grasp scheduler, provide chain planners, consumers, high quality assurance specialists, and distribution managers

- Finance: controller, costing accountant, and monetary planning supervisor or budgeting supervisor

Irrespective of who’s in your S&OP group, the primary steps within the course of must be the identical.

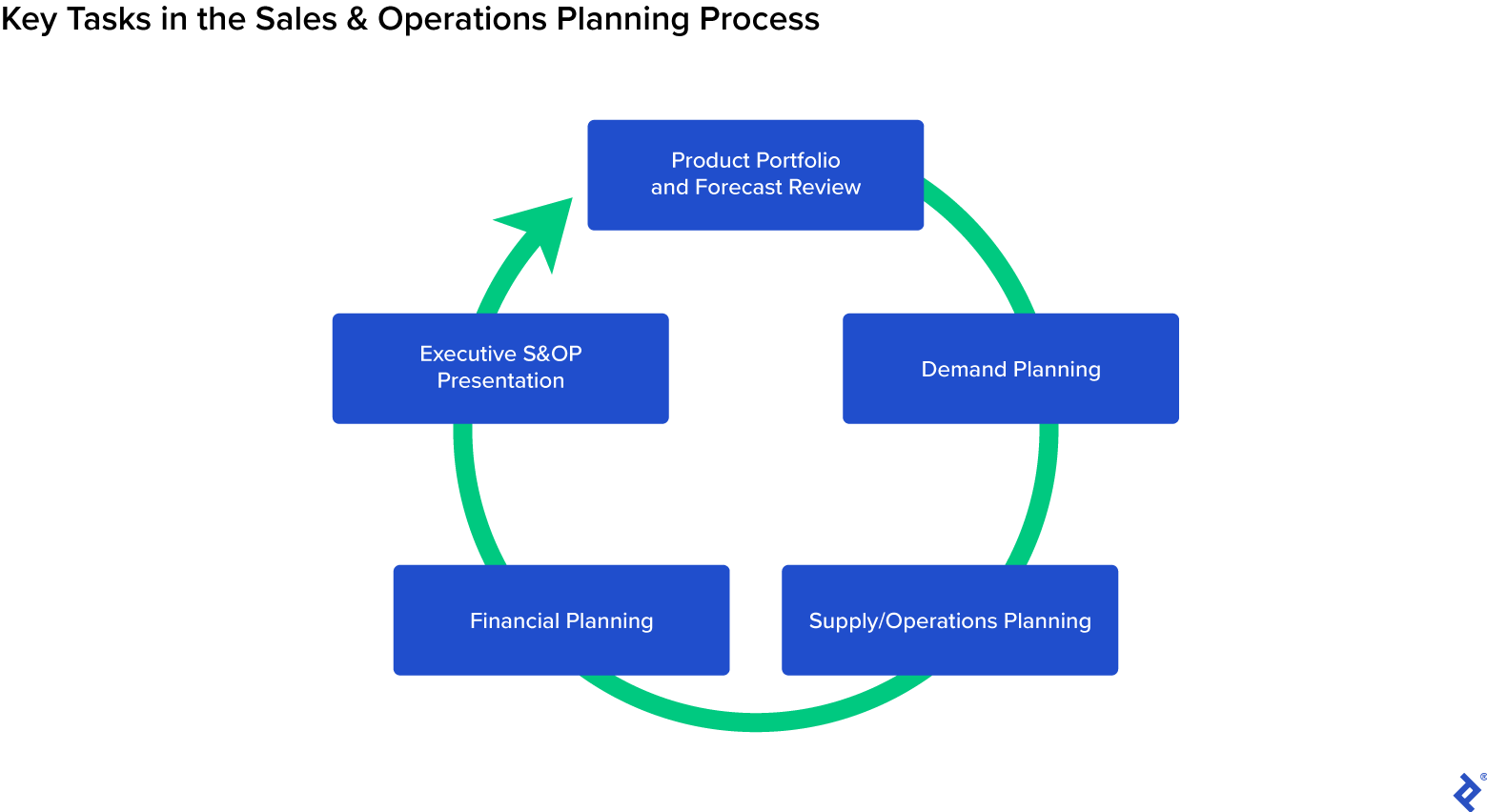

Core Steps within the S&OP Course of

For correct S&OP implementation, you’ll want to perform—and repeat—all of those steps, however you’ll be able to adapt them on your agency. For instance, if one in all these conferences turns into too lengthy or difficult, you’ll be able to divide it into two more-manageable ones. However, if a number of conferences appear transient, you’ll be able to mix them into one session.

- Product portfolio and forecast assessment: This step goals to ship a unified company product technique by analyzing the life cycle of every merchandise within the firm product portfolio. To ensure that the S&OP group to see an built-in assessment of every services or products that may go to market and be supplied to clients, all departments concerned within the S&OP course of contribute knowledge, like earlier gross sales historical past and gross sales forecasts, stock, manufacturing capability, projected demand, and exterior occasions that would have an effect on demand. The step additionally takes into consideration the latest monetary knowledge, comparable to manufacturing prices, value, margins, holding prices, transportation prices, and so forth. Since S&OP is an iterative course of, after the primary time by way of, the plan obtained within the final S&OP govt presentation can be built-in into this product assessment.

- Demand planning: The purpose of this step is to make sure your organization’s sources and gross sales objectives are aligned, in order that your manufacturing and provide chain can produce the stock to fulfill anticipated buyer demand promptly. This course of makes use of previous demand patterns and forecasts to foretell want for services and products all through the availability chain. Historic gross sales knowledge, market traits, and different related info from the completely different departments are analyzed to estimate how a lot of a services or products will probably be required. Enter and suggestions from the operations group are particularly necessary right here as a way to outline lifelike demand ranges in response to product availability. The ensuing demand plan can be analyzed and adjusted by the S&OP group to maintain it aligned with strategic firm objectives like product line development, low cost proportion, and gross margins.

- Provide/operations planning: Subsequent, the demand plan is translated right into a provide plan, in order that stock and provides can be found to assist the projected demand. A number of the duties right here embody forecasting demand for uncooked supplies, parts, and different inputs; figuring out and assessing potential suppliers; monitoring provider efficiency; figuring out and assessing potential dangers to the availability chain (like freight limitations, provider disruptions, or adjustments in market circumstances), and creating plans to mitigate these dangers; and ensuring that the availability plan aligns with firm priorities, comparable to stock ranges, useful resource utilization, fill charges, and proportion of excellent orders.

- Monetary planning: Based mostly on the demand and provide/operations plans, the monetary group’s plan appears on the anticipated demand for a services or products and the associated prices to estimate the corporate’s monetary efficiency over a selected interval. The principle deliverables listed here are the projected P&L assertion, the projected money circulate assertion, and the funds compliance report. Price is analyzed as a secondary concern. The cross-functional S&OP group opinions and discusses the plan alongside the demand and provide plans to see that the corporate’s monetary objectives are aligned with its operational objectives and that the corporate has the sources it wants to fulfill demand and obtain its monetary objectives.

- Govt S&OP presentation: Subsequent, the S&OP group presents the details of the overarching plan to senior administration to get govt enter, approval, and buy-in. Usually, the group and management additionally take into account “what if” situations to make selections and closing plan changes. Then the S&OP group incorporates suggestions from senior administration and opinions the outcomes earlier than continuing. The principle deliverable of this assembly is a complete, built-in plan that aligns with the corporate’s strategic, operational, and monetary targets. This plan may also inform step one of the subsequent interval’s S&OP.

This S&OP cycle is normally repeated month-to-month, permitting stakeholders to remain aligned whereas regularly refining the long-term plan based mostly on adjustments to enterprise wants, the availability chain, or market circumstances. And for the reason that day-to-day actions of each division join on to the long-term plan, each can act swiftly to handle unexpected conditions. Any adjustments in wants or circumstances, together with new or altered constraints, must be communicated instantly to your complete S&OP group. Having a long-term plan that’s revised typically additionally helps your organization attain agreements with strategic distributors and clients, improve enterprise responsiveness, and defend margins.

5 Ideas for S&OP Success

All through my 25 years within the subject, I’ve seen 5 implementation points constantly impede profitable S&OP. These are the very best practices your corporation ought to comply with so as to reap the total advantages of S&OP:

Collaborate Frequently

Many firms see the S&OP course of as linear: The industrial group presents a requirement requirement, and the operations group generates sufficient stock to assist it. This method received’t enhance enterprise responsiveness. As a substitute, you could get all contributors on the multidisciplinary S&OP group to work collectively—not sequentially—from the beginning. The industrial group wants to speak with operations whereas creating its demand plan so operations can begin producing stock. Likewise, operations has to speak to the finance group to find out how a lot stock the corporate can afford to provide.

This sort of interlacing collaboration isn’t a given. Once I began working with the native workplace of a big meals manufacturing and processing company in 2005, the corporate didn’t have a devoted S&OP group or an efficient course of. Though the industrial division offered a month-to-month demand plan, operations all the time altered it earlier than creating its personal plan—with out sharing it with industrial. So there have been two completely different plans operating in parallel.

Once I optimized S&OP at this firm, the group I fashioned began doing goal historic knowledge evaluation and used the insights we gathered to appropriate the preliminary plan. The consequence? A unified, environment friendly plan that elevated productiveness, lower spending, and minimized losses. Finally, operations was paying for the extent of producing that match the industrial group’s promotional methods—and the finance group had the money circulate to assist them. As soon as they noticed these advantages, the departments have been extra prepared to collaborate with each other, making subsequent planning quicker and simpler.

Convey Management on Board

Having a CEO or normal supervisor who’s not totally dedicated to the plan set by the S&OP group considerably weakens the method’s effectiveness. S&OP strives to carry and preserve all departments in alignment. If a CEO isn’t conscious of the method or doesn’t totally perceive it and units a distinct course, subordinates must comply with. At greatest, the corporate’s effort will probably be fragmented; at worst, the departments will probably be working at cross functions. But, executives’ decision-making is usually not aligned with S&OP as a result of they take into account it an non-compulsory addition, not as a system totally built-in into their day-to-day conferences and operations.

Once I applied S&OP in a big cosmetics company in Latin America, my first transfer was to sit down with the overall supervisor of one of many enterprise models to debate the steps concerned. The supervisor already had a month-to-month committee assembly along with his senior workers, so he didn’t like the thought of an “further” appointment. I steered merging the conferences and reviewing the primary enterprise KPIs and points together with the S&OP plan. Our first session lasted greater than 10 hours. Nevertheless it confirmed the GM the methodology’s advantages, and he permitted its use for the corporate. He helped outline the plan, agreed to handle it, and gave the group unconditional assist. Over time, the manager S&OP assembly was shortened to lower than three hours.

Insist on Accountability

At each firm, an S&OP course of requires each the each day execution of duties with due dates and a clear chain of obligations. Each participant have to be accountable for the duties they settle for. Accountability must be a given, however I’ve seen many firms neglect it. And the worst scenario an S&OP group can face is realizing the plan failed as a result of someone didn’t full a job.

Quite than allow failures, senior administration should maintain all S&OP group members accountable. For that to work, obligations have to be clearly outlined. Particular person assignments have to be specified and tracked, and there must be repercussions for not fulfilling duties—in addition to incentives for succeeding. One option to accomplish that is to tie earnings to efficiency.

Flip Off the Noise

For S&OP to perform effectively, focus is vital. In lots of implementations I’ve labored on, group members waste an excessive amount of time reviewing historic outcomes, actually because they’re arguing and making an attempt to justify their selections or assigning blame for previous failures. Historic outcomes ought to solely be factors of reference for steady enchancment of the S&OP course of. My normal rule: Your group ought to speculate one-third of its time wanting on the previous and two-thirds defining and analyzing its plan for the longer term.

One other type of noise is poor knowledge high quality or administration. Examples of this embody knowledge that’s inconsistent throughout departments, in addition to lack of readability about knowledge definitions and preparation. At its first assembly, your S&OP group ought to outline, agree upon, and implement a proper methodology for acquiring, unifying, and presenting info. This manner, you’ll be able to shortly make selections based mostly on knowledge all departments belief, serving to the corporate pivot even within the face of an industry-changing disruption.

Maintain Info Flowing

Corporations can solely react as shortly as their communication channels and practices enable. Based mostly on my observations, companies that responded successfully to COVID-19-related provide chain limitations gathered and moved info swiftly all through their organizations as they made collaborative selections. Industrial, operational, and monetary departments additionally want stable communication processes to remain in alignment as they reply to crises. This implies having conferences not less than as soon as every week and sharing updates and data each day.

I noticed the consequences of insufficient communication on the meals firm I discussed earlier. The industrial and operational departments didn’t share info constantly and didn’t comply with a unified plan. Operations didn’t know the industrial group’s gross sales quantity, so it generated an excessive amount of product. Consequently, the corporate had unbalanced stock ranges and enormous volumes of product scrap on account of expiration, which means losses of near $1 million. To deal with this concern, I developed an Excel spreadsheet that carried out first-expired, first-out stock administration with a given forecast and stock. This generated warnings that prompted operations to recommend changes to the estimates, letting the industrial group create promotions for at-risk merchandise. Weekly conferences between groups strengthened this course of, and the S&OP group diminished product write-offs by 80% in a single yr.

Info like stock ranges of at-risk merchandise can’t wait. To extend responsiveness, firms ought to implement not solely the month-to-month S&OP cycle communication but additionally good communication practices for day-to-day functioning, which some organizations name gross sales and operations execution (S&OE).

Optimized S&OP implementation helps your organization anticipate and tackle issues shortly and effectively. The long-term planning concerned improves your means to mitigate disruptions to your provide chains or different networks, whereas the emphasis on common assessment and revision retains enterprise as common a precedence. And whereas the preliminary setup could require time, thought, and energy, this course of will enable your organization to reply adroitly to no matter comes at it. You possibly can’t cease change—however you might be prepared to fulfill it.