On the floor, Puma’s traditional suede sneaker has seemed the identical since 1968, however the firm just lately unveiled a model that may biodegrade into farm-ready compost. The RE:SUEDE mission is the primary from Puma’s Round Lab. The corporate printed the outcomes of its experiment in November after two years of analysis.

Footwear manufacturing accounts for 1.4 p.c of annual international greenhouse gasoline emissions, in response to a 2018 Quantis research — roughly equal to the emissions of Canada. Manufacturing accounts for 43 p.c of these emissions, and extracting and processing uncooked supplies 34 p.c, the report discovered. Making a pair of sneakers generates 30 kilos of CO2, in response to an evaluation by MIT in 2013. A typical shoe comprises a number of supplies tightly sewn collectively — leather-based, plastic, cotton, rubber, synthetics and so forth — and is thus very troublesome to recycle. Ninety p.c of previous sneakers find yourself in landfill websites.

Puma’s circularity targets for 2025 embody providing product takebacks in massive markets; halving landfill waste from manufacturing; and growing recycled supplies for leather-based, rubber, cotton and polyurethane.

“We should actively transfer the needle when it comes to decreasing power consumption, waste, emissions,” Puma’s senior head of innovation, Romain Girard, stated through e mail. “Circularity is connecting the dots on lots of these facets. … Experimenting with merchandise that remove waste on the end-of-use stage permits us to rethink the way in which we sort out the waste generated from our business,” Girard stated.

The Bavarian shoemaker launched the RE:SUEDE outcomes with a handbook to assist different organizations pursuing circular-economy initiatives.

“By throwing ourselves on the market, we’ve got had many inventors, creators and producers attain out to share their concepts with us,” Girard stated. “That is necessary to us as we strongly consider that dialog and collaboration will make the distinction.”

How Puma’s experiment labored

In early 2022 Puma invited customers to affix the RE:SUEDE pilot, deciding on 500 individuals from 2,000 candidates in Germany to put on the sneakers about twice per week for six months.

Puma sought to reply 4 questions:

- May Puma make a compostable shoe that individuals truly preferred to put on? Greater than two-thirds of pilot testers stated they might advocate the RE:SUEDE to others, though 57 p.c stated it was uncomfortable.

- Would contributors mail again the sneakers for composting? 4 hundred and twelve of them did.

- May the sneakers rework into farm-ready compost? Not solely. The uppers decayed properly sufficient for use as customary compost however the soles took too lengthy.

- May it scale? Puma’s Round Lab is exploring new initiatives, together with its RE:FIBRE textile recycling effort with skilled soccer jerseys.

How the sneakers composted

The important thing situation, in fact, is whether or not the shoe will truly degrade totally sufficient for use in agriculture. Initially, a number of waste administration firms declined to work with Puma, as a result of introducing new supplies to an industrial compost facility dangers contaminating the compost.

But the mission piqued the curiosity of Marthien van Eersel, Ortessa’s supervisor of supplies and improvements. “We considered it and stated, what the heck, let’s examine what it’s,” he stated. “Now we have a particular testing methodology, the place we will introduce biodegradable supplies into our terminal, [and] they won’t contaminate the remainder of the inexperienced family waste or the compost that we make.”

The non-public Dutch firm’s Valor Composting Facility turns 50,000 tonnes of family meals waste and backyard trimmings into 24,000 tonnes of Grade A compost for farms every year.

Between March and June, Ortessa combined Puma’s sneakers with the inexperienced waste from properties and left them to interrupt down at excessive warmth inside one in every of its fourteen 150 square-meter concrete tunnels.

Each two weeks, the corporate sieved the decaying materials — something smaller than 1.5 inches in diameter is compostable; below .4 inch turns into Grade A compost.

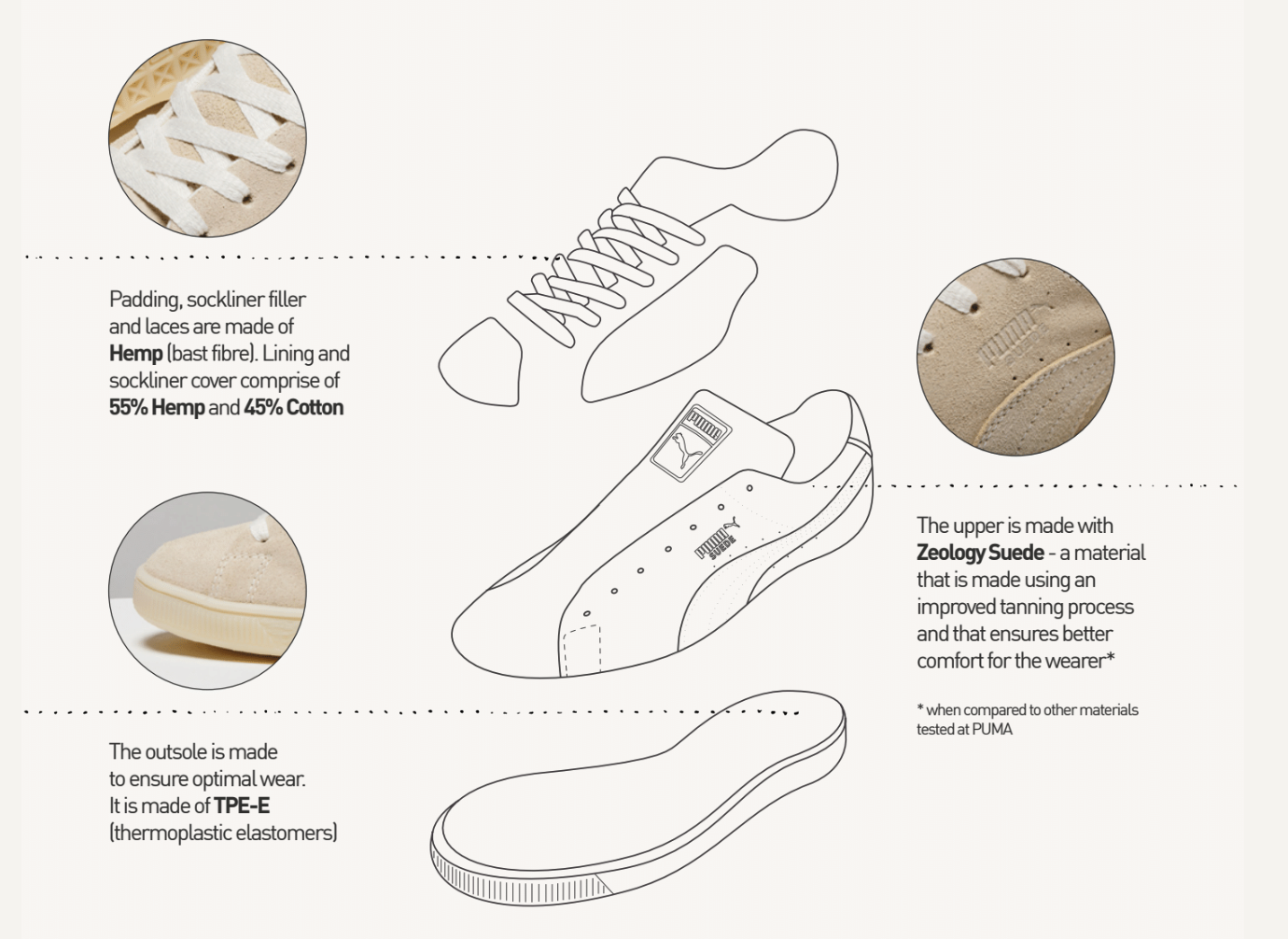

RE:SUEDE’s uppers are manufactured from hemp, cotton and Zeology suede, tanned with a unhazardous zeolite-based components. These supplies degraded pretty rapidly. After 2.5 months, most of it was usable. However Ortessa anticipated the soles — produced from TPE-E, a versatile polymer — would have wanted about 4 extra months to totally break down.

Increasing the inputs for compost

Ortessa helps a handful of different companies to check whether or not textiles, disposable meals packaging, cups and consuming utensils could be composted. With sufficient quantity from companies paying Ortessa, van Eersel hopes Ortessa might finally deal with greater than family waste.

“So for us, the enterprise mannequin is not simply garments, sneakers, it is extra all of the biodegradable supplies which have confirmed in our testing methodology that they’ll decompose inside our working parameters,” he stated.

Subsequent yr, Europe will impose a ban on stable plastic meals packaging and paper cups with plastic liners. Using compostable, fossil-fuel-free cups, packing containers and cutlery will rise, and so will the necessity to handle them, van Eersel stated.

Every part previous is new once more

RE:SUEDE isn’t Puma’s first stab at a biodegradable sneaker. Ten years in the past the corporate launched an InCycle design that includes natural cotton and linen, with soles of APINATbio plastic.

Since then, the expertise has improved, Girard stated. “The RE:SUEDE is an easy shoe, (comprising) just a few items and parts,” Girard stated. “We’re at the moment engaged on exploring an identical idea however primarily based on extra complicated merchandise which have increased useful advantages.”

Blueview Footwear, OAT Sneakers and Native Sneakers are among the many smaller firms additionally touting biodegradable fashions. Blueview used algae in its 52-percent biobased foam soles, which it says can biodegrade within the ocean.

Puma has talked to many of those startups, Girard stated. “We share the identical targets but right here at Puma we’re growing improvements that may be utilized at scale,” he stated. “We see the chance to scale up giving extra individuals entry to most of these merchandise. We additionally see the prospect to increase the product portfolio on this area with totally different silhouettes and product sorts.”