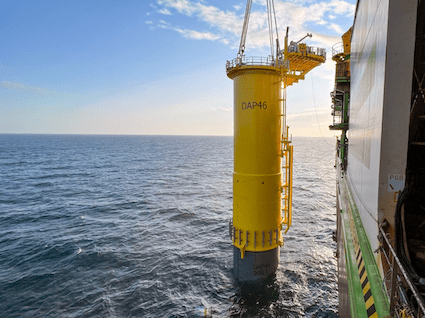

Marking a seemingly essential advance in wind turbine fabrication, a bunch of companies has introduced the primary ever incorporation of an electron-beam-welded part in an offshore wind turbine monopile basis (transition piece). The ensuing monopile is ready for set up within the second section of Dogger Financial institution Wind Farm, which is positioned greater than 130km off the Northeast coast of England.

Monopiles are at the moment fabricated utilizing typical strategies resembling submerged arc welding (SAW), however the consortium has demonstrated that electron beam (EB) welding is considerably faster, cheaper, cleaner, extra vitality environment friendly and produces top quality welds with wonderful fatigue properties.

The work was accomplished as a collaboration between Cambridge Vacuum Engineering (CVE), SSE Renewables, Sif Group, and TWI.

The kind of electron beam welding expertise used – referred to as EbflowTM – is described as an revolutionary improvement throughout the electron beam welding trade. As an alternative of welding inside a pricey and size-limiting vacuum chamber, Ebflow makes use of a neighborhood vacuum system that creates and maintains a vacuum round solely the seam that’s being welded. This method unleashes the potential to make use of EB welding on giant buildings, resembling the largest monopiles, whereas decreasing prices and enhancing productiveness. The expertise – developed by CVE – has been proven to weld monopiles “not less than 25 instances sooner than present strategies, while utilizing 90% much less vitality, costing 88% much less, and producing 97% much less CO2 emissions than SAW strategies.”

The undertaking required set up of an Ebflow system at Sif’s Maasvlakte 2 facility in Rotterdam to carry out a number of longitudinal welds on 2750 mm size seams on 8m diameter rolled cans with a wall thickness of between 67-85mm. Qualification of the welding machine, weld procedures and operators have been witnessed by third celebration inspectors and the regulatory physique, DNV, which subsequently issued a expertise qualification for EB welding and non-destructive testing (NDT) of the longitudinal seams produced with the method. The excellent efficiency testing programme proved that Ebflow produces welds with fatigue energy that’s not less than nearly as good, if not higher, than noticed in equal arc welded joints.

The ensuing can was included right into a monopile transition piece in January 2023 and is scheduled to be put in offshore as a part of a basis in Dogger Financial institution Wind Farm in late 2023.

Olly Cass, SSE Renewables Venture Director for Dogger Financial institution Wind Farm stated:

“This can be a ‘first-in-class’ undertaking, establishing this UK innovation as a world-leading expertise. With monopile kind foundations accounting for over 90% of foundations utilized in UK initiatives, Ebflow RPEB may realise vital value financial savings on future initiatives.

“These substantial financial savings won’t solely profit the UK offshore engineering trade however may very well be handed on to UK vitality shoppers.

“We’re proud to be pioneering this revolutionary method on Dogger Financial institution Wind Farm by demonstrating its capabilities on a crucial offshore element and this could not have been potential with out the nice collaborative work with Cambridge Vacuum Engineering (CVE), Sif Group, and TWI. We’re enthusiastic about what may very well be achieved by scaling up this technique to select up the tempo as we work in the direction of web zero targets.”

Dogger Financial institution Wind Farm is a three way partnership between SSE Renewables, Equinor and Vårgrønn. The farm is being inbuilt three 1.2GW phases and is predicted to start out producing energy this summer time.