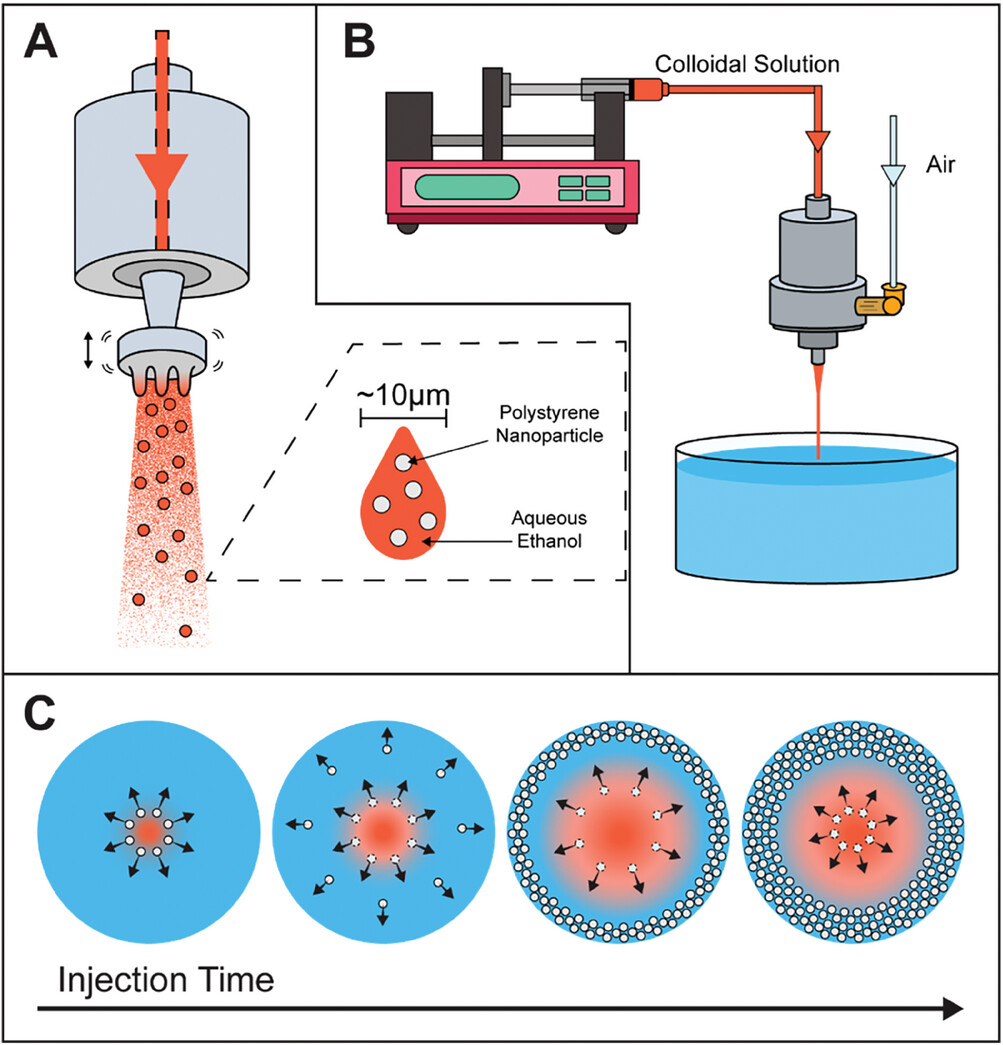

a) Schematic diagram of aerosolizing nozzle producing micron-scale dishing out droplets carrying submicron colloidal particles. b) Schematic diagram of monolayer self-assembly system. c) Course of movement displaying self-assembly of submicron colloidal particles self-assembling at an air–water interface as a perform of injection time. (Left) Atomized droplets of aqueous alcohol dishing out droplets (orange) impinge on the water’s floor (blue). The alcohol generates a floor stress gradient (orange) which propels submicron colloidal particles (white) radially away from the impression level. Over time steady injection causes submicron particles to build up into an annulus and self-assemble into an ordered monolayer (Proper). (Reprinted with permission by Wiley-VCH Verlag)

The brand new methodology, dubbed aerosol-assisted self-assembly, leverages an ultrasonic spray nozzle to generate a advantageous mist containing the nanoparticles suspended in liquid droplets simply microns in dimension. This nanoparticle-laden aerosol is targeted right into a slim beam and aimed on the floor of a water tub. When the microdroplets strike the water, the nanoparticles are effectively transferred to the air-water interface, the place they quickly self-assemble into an ordered monolayer.

The breakthrough lies in utilizing an ultrasonic spray nozzle, which leverages piezoelectric transducers vibrating at 120 kilohertz to generate a advantageous aerosol mist from the nanoparticle resolution. This mist accommodates discrete liquid droplets simply 15-25 microns in diameter. By focusing these droplets right into a slim beam geared toward water’s floor, the nanoparticles will be effectively transferred to the air-water interface when the droplets strike.

The underlying physics includes delicately balancing interfacial stress and dissipating the droplets’ kinetic vitality to forestall rupturing the water’s floor. This prevents nanoparticle loss into the majority liquid. In the meantime, surfactant molecules within the aerosol induce robust floor flows alongside the air-water interface through the Marangoni impact. This helps propel the nanoparticles away from the impression website with out aggregation.

a) Schematic diagram of aerosolizing nozzle producing micron-scale dishing out droplets carrying submicron colloidal particles. b) Schematic diagram of monolayer self-assembly system. c) Course of movement displaying self-assembly of submicron colloidal particles self-assembling at an air–water interface as a perform of injection time. (Left) Atomized droplets of aqueous alcohol dishing out droplets (orange) impinge on the water’s floor (blue). The alcohol generates a floor stress gradient (orange) which propels submicron colloidal particles (white) radially away from the impression level. Over time steady injection causes submicron particles to build up into an annulus and self-assemble into an ordered monolayer (Proper). (Reprinted with permission by Wiley-VCH Verlag)

The brand new methodology, dubbed aerosol-assisted self-assembly, leverages an ultrasonic spray nozzle to generate a advantageous mist containing the nanoparticles suspended in liquid droplets simply microns in dimension. This nanoparticle-laden aerosol is targeted right into a slim beam and aimed on the floor of a water tub. When the microdroplets strike the water, the nanoparticles are effectively transferred to the air-water interface, the place they quickly self-assemble into an ordered monolayer.

The breakthrough lies in utilizing an ultrasonic spray nozzle, which leverages piezoelectric transducers vibrating at 120 kilohertz to generate a advantageous aerosol mist from the nanoparticle resolution. This mist accommodates discrete liquid droplets simply 15-25 microns in diameter. By focusing these droplets right into a slim beam geared toward water’s floor, the nanoparticles will be effectively transferred to the air-water interface when the droplets strike.

The underlying physics includes delicately balancing interfacial stress and dissipating the droplets’ kinetic vitality to forestall rupturing the water’s floor. This prevents nanoparticle loss into the majority liquid. In the meantime, surfactant molecules within the aerosol induce robust floor flows alongside the air-water interface through the Marangoni impact. This helps propel the nanoparticles away from the impression website with out aggregation.

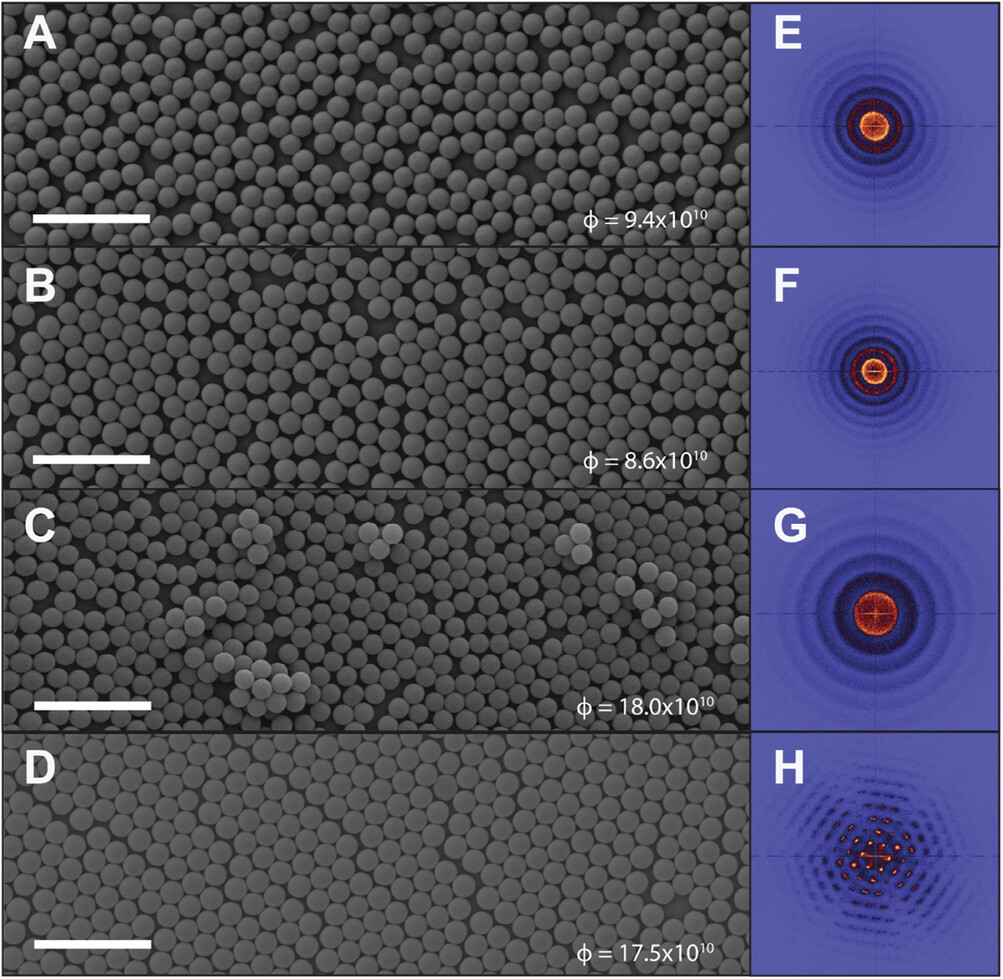

a–d) Scanning electron microscope (SEM) photographs of nanoparticle (NP) monolayers self-assembled at low Φ (a,b) and excessive Φ (c,d) and colloidal options with low |𝜁| (a,c) and excessive |𝜁| (b,d). Fourier remodel of self-assembled NP monolayers ready through Technique 2 with |𝜁| = 30 mV (e,g), |𝜁| = 70 mV (f,h). All scale bars proven are 5 μm. (Reprinted with permission by Wiley-VCH Verlag)

A key benefit of this system is pace. The researchers demonstrated nanoparticle self-assembly charges as much as 268 sq. centimeters per minute—93 occasions sooner than the earlier state-of-the-art. Such fast meeting facilitates the scalable fabrication of nanoparticle sheets throughout massive floor areas. This has been an everlasting hurdle for real-world functions of those nanomaterials.

The research gives new insights into the bodily elements governing environment friendly nanoparticle switch and meeting in the course of the course of. Particularly, the researchers discovered that tailoring the electrical cost of the nanoparticles is crucial. Nanoparticles with a excessive electrical cost, or zeta potential, self-assemble into extremely ordered crystals way more successfully. Such charged particles resist irreversibly sticking collectively, enabling defects within the rising nanostructure to self-correct over time.

By cautious management of the nanoparticle floor properties and deposition flux, the researchers fabricated exceptionally uniform and defect-free assemblies of nanocrystals over 50 sq. inches in space. It is a scale related for business manufacturing. Intriguingly, the approach additionally efficiently assembled extra advanced nanoparticles, together with silicon-titanium core-shell particles with an outer polymer coating. This demonstrates the potential compatibility with a various array of nanomaterials.

The nanoparticle sheets retain their structural integrity when transferred to quite a lot of surfaces, together with a curved spherical substrate. This flexibility might allow patterning of next-generation optics and even versatile and wearable gadgets. To focus on potential functions, the researchers used their approach to manufacture vivid optical coatings exhibiting intense structural coloration.

By providing fast fabrication, scalability, and broad materials flexibility, the brand new directed aerosol-assembly methodology gives a pivotal platform for translating a number of lab-based improvements into business nanoparticle applied sciences. The undertaking lead, Professor Edward Yu, famous that their approach is very modular and leverages tools already commonplace in industrial manufacturing settings.

The low complexity and excessive throughput might quickly make intricate optical metamaterials, ultra-efficient photovoltaics, and beforehand inaccessible versatile nanodevices cost-competitive with much less refined applied sciences. This new manufacturing paradigm might assist pioneer markets for nanotechnology in rising economies. With additional growth, Yu means that directed aerosol self-assembly of nanoparticles might complement and even substitute present lithographic strategies for nanofabrication, unlocking new alternatives throughout scientific disciplines.

a–d) Scanning electron microscope (SEM) photographs of nanoparticle (NP) monolayers self-assembled at low Φ (a,b) and excessive Φ (c,d) and colloidal options with low |𝜁| (a,c) and excessive |𝜁| (b,d). Fourier remodel of self-assembled NP monolayers ready through Technique 2 with |𝜁| = 30 mV (e,g), |𝜁| = 70 mV (f,h). All scale bars proven are 5 μm. (Reprinted with permission by Wiley-VCH Verlag)

A key benefit of this system is pace. The researchers demonstrated nanoparticle self-assembly charges as much as 268 sq. centimeters per minute—93 occasions sooner than the earlier state-of-the-art. Such fast meeting facilitates the scalable fabrication of nanoparticle sheets throughout massive floor areas. This has been an everlasting hurdle for real-world functions of those nanomaterials.

The research gives new insights into the bodily elements governing environment friendly nanoparticle switch and meeting in the course of the course of. Particularly, the researchers discovered that tailoring the electrical cost of the nanoparticles is crucial. Nanoparticles with a excessive electrical cost, or zeta potential, self-assemble into extremely ordered crystals way more successfully. Such charged particles resist irreversibly sticking collectively, enabling defects within the rising nanostructure to self-correct over time.

By cautious management of the nanoparticle floor properties and deposition flux, the researchers fabricated exceptionally uniform and defect-free assemblies of nanocrystals over 50 sq. inches in space. It is a scale related for business manufacturing. Intriguingly, the approach additionally efficiently assembled extra advanced nanoparticles, together with silicon-titanium core-shell particles with an outer polymer coating. This demonstrates the potential compatibility with a various array of nanomaterials.

The nanoparticle sheets retain their structural integrity when transferred to quite a lot of surfaces, together with a curved spherical substrate. This flexibility might allow patterning of next-generation optics and even versatile and wearable gadgets. To focus on potential functions, the researchers used their approach to manufacture vivid optical coatings exhibiting intense structural coloration.

By providing fast fabrication, scalability, and broad materials flexibility, the brand new directed aerosol-assembly methodology gives a pivotal platform for translating a number of lab-based improvements into business nanoparticle applied sciences. The undertaking lead, Professor Edward Yu, famous that their approach is very modular and leverages tools already commonplace in industrial manufacturing settings.

The low complexity and excessive throughput might quickly make intricate optical metamaterials, ultra-efficient photovoltaics, and beforehand inaccessible versatile nanodevices cost-competitive with much less refined applied sciences. This new manufacturing paradigm might assist pioneer markets for nanotechnology in rising economies. With additional growth, Yu means that directed aerosol self-assembly of nanoparticles might complement and even substitute present lithographic strategies for nanofabrication, unlocking new alternatives throughout scientific disciplines.

By

Michael

Berger

– Michael is creator of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Know-how,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Abilities and Instruments Making Know-how Invisible

Copyright ©

Nanowerk LLC

Grow to be a Highlight visitor creator! Be a part of our massive and rising group of visitor contributors. Have you ever simply revealed a scientific paper or produce other thrilling developments to share with the nanotechnology neighborhood? Right here is the way to publish on nanowerk.com.