| Apr 29, 2023 |

|

(Nanowerk Information) When fossil fuels, but additionally biofuels, are burned, giant quantities of the vitality are misplaced as waste warmth. Thermoelectric supplies may convert this warmth into electrical energy, however they don’t seem to be but environment friendly sufficient for technical software. A workforce from the Max Planck Institut für Eisenforschung has now elevated the effectivity of a thermoelectric materials by elucidating the affect of the microstructure on the fabric and optimizing the fabric’s properties by including titanium.

|

|

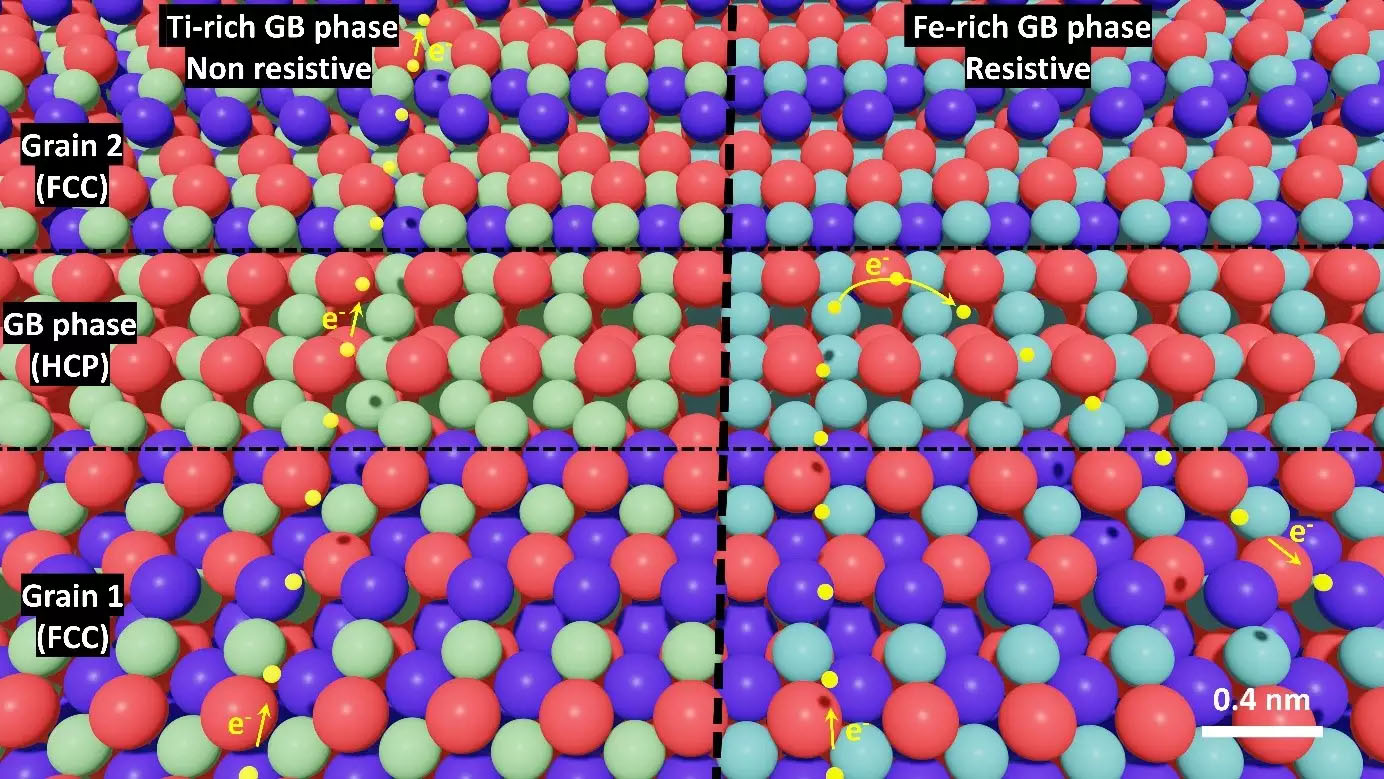

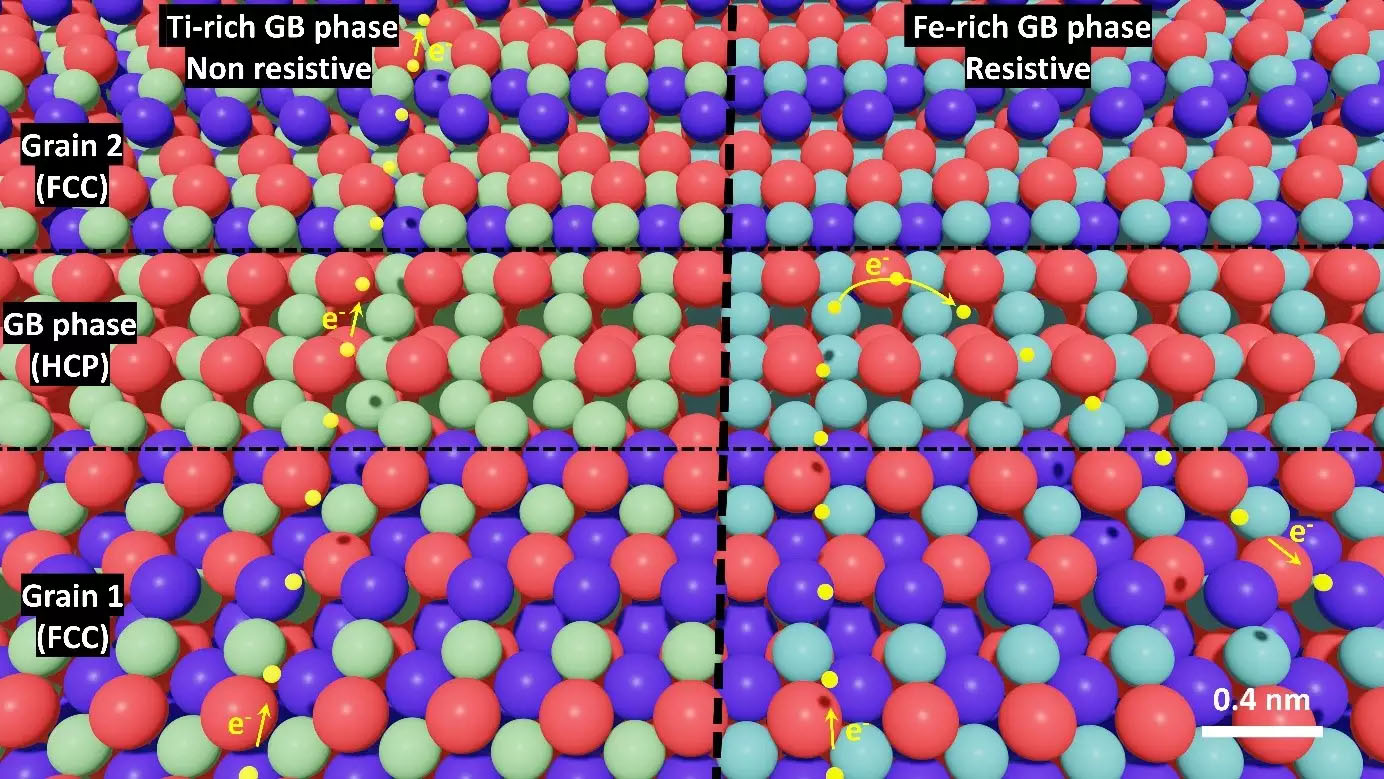

| The chemistry and atomic association of the grain boundary phases outline the electron transport by way of the grain boundaries. The titanium-rich grain boundary section supplies a conductive path (left) whereas the iron-rich grain boundary section is resistive to electrons (proper). (Picture: R. Bueno Villoro, Max-Planck-Institut für Eisenforschung)

|

|

The local weather disaster is forcing us not solely to section out fossil fuels, but additionally to save lots of vitality. Particularly the place fossil fuels can’t but get replaced so rapidly, they need to not less than be used effectively – for instance, by producing electrical energy from the waste warmth of energy-intensive industrial crops or energy stations.

|

|

At current, round 17 % of the vitality utilized in European business is misplaced as waste warmth. It may very well be harnessed with the assistance of thermoelectric supplies. In such thermoelectrics, {an electrical} voltage is generated when they’re uncovered to a temperature distinction. Nevertheless, present thermoelectrics should not environment friendly sufficient for use on a big industrial scale.

|

|

A analysis workforce led by the Düsseldorf-based Max Planck Institut für Eisenforschung has now succeeded in optimizing a thermoelectric, because the supplies are recognized in technical jargon, and thus come nearer to industrial use.

|

|

The workforce revealed its findings within the journal Superior Vitality Supplies (“Grain boundary phases in NbFeSb half-Heusler alloys: A brand new avenue to tune transport properties of thermoelectric supplies”).

|

|

The workforce studied an alloy of niobium, iron and antimony that converts waste warmth into electrical energy at temperatures starting from about 70 to greater than 700 levels Celsius with an effectivity of eight % – making the alloy at present one of the vital environment friendly thermoelectrics. Solely a fabric made from bismuth and tellurium achieves comparable values. Nevertheless, bismuth telluride is simply appropriate to be used at comparatively low temperatures and is mechanically much less steady than the thermoelectric made from niobium, iron and antimony. As well as, its constituents are much less available.

|

Titanium improves electrical conductivity

|

|

To additional improve the effectivity of the thermoelectric made from niobium, iron and antimony, the researchers targeted on its microstructure. Like most metals, thermoelectric supplies are composed of tiny crystals. The composition and construction of the grains, in addition to the properties of the areas between them, generally known as grain boundaries, are essential to the thermal and electrical conductivity of thermoelectric supplies.

|

|

Earlier analysis has proven that grain boundaries cut back each the thermal and electrical conductivity of the fabric. For the best doable effectivity, the thermal conductivity ought to be as little as doable in order that the warmth, i.e. the vitality, stays within the materials. {The electrical} conductivity, nevertheless, ought to be excessive so as to convert as a lot warmth as doable into electrical energy.

|

|

The objective of the workforce from the Max Planck Institut für Eisenforschung, the Northwestern College (USA) and the Leibniz Institute for Strong State and Supplies Analysis Dresden was subsequently to optimize the grain boundaries in such a method that solely the thermal conductivity is lowered, however not {the electrical} conductivity.

|

|

“We used scanning transmission electron microscopes and atom probes to review the microstructure of the alloy all the way down to the atomic degree,” says Ruben Bueno Villoro, a doctoral scholar on the Max Planck Institut für Eisenforschung. “Our evaluation has proven that grain boundaries should be optimized to enhance electrical and thermal properties.”

|

|

“The smaller the grains within the materials, the upper the variety of grain boundaries and the more serious {the electrical} conductivity,” explains Siyuan Zhang, challenge chief in the identical analysis group. “It would not make sense to extend the dimensions of the grains within the materials, as a result of bigger grains would improve thermal conductivity and we might lose warmth and subsequently vitality. Subsequently, we needed to discover a technique to improve {the electrical} conductivity regardless of the small grains.”

|

|

The researchers solved the issue by enriching the fabric with titanium, which, amongst different issues, accumulates on the grain boundaries and will increase electrical conductivity. On this method, they elevated the thermoelectric effectivity of the alloy by as much as 40 %. For sensible functions, nevertheless, the effectivity nonetheless wants to extend considerably.

|

Subsequent step: selective enrichment of titanium at grain boundaries

|

|

Now the analysis workforce is analyzing methods to selectively add titanium solely to grain boundaries with out enriching your complete materials with titanium. This technique saves prices and largely preserves the unique chemical composition of the thermoelectric materials. The present analysis reveals how purposeful properties could be linked to the atomic construction of a fabric to particularly optimize sure properties.

|