(Nanowerk Information) Carbon nanotubes have lengthy tantalized researchers with their extraordinary mechanical and digital properties. As one-dimensional nanostructures with outstanding mechanical energy and electrical conductivity, CNTs have been eyed for next-generation composites, power storage gadgets, sensors and extra. But realizing their promise has confirmed an everlasting problem.

CNTs have ultra-high floor power and readily type massive bundles relatively than remaining as individualized tubes, severely compromising resultant materials properties. Exfoliating these bundles, significantly in answer, has remained an immense issue regardless of intense R&D efforts over 30+ years using covalent and noncovalent functionalization methods.

Covalent approaches disrupt the CNTs’ pristine sp2 carbon networks, damaging their intrinsic properties. Noncovalent strategies like surfactants and polymers have had restricted success in debundling smaller diameter single-wall CNTs (SWCNTs), particularly longer excessive facet ratio tubes most popular for optimum conductivity and energy. And just about all ways have struggled to exfoliate particular SWCNT varieties, hindering enrichment in metallic SWCNTs boasting far increased conductance than their semiconducting counterparts.

Now, chemists at Israel’s Weizmann Institute of Science have demonstrated a facile new aqueous answer processing path to efficiently exfoliate SWCNTs utilizing a standard natural dye molecule – purpurin.

They revealed their findings in Superior Practical Supplies (“Extremely Conductive Sturdy Carbon Nanotube Networks for Robust Buckypapers and Clear Electrodes”).

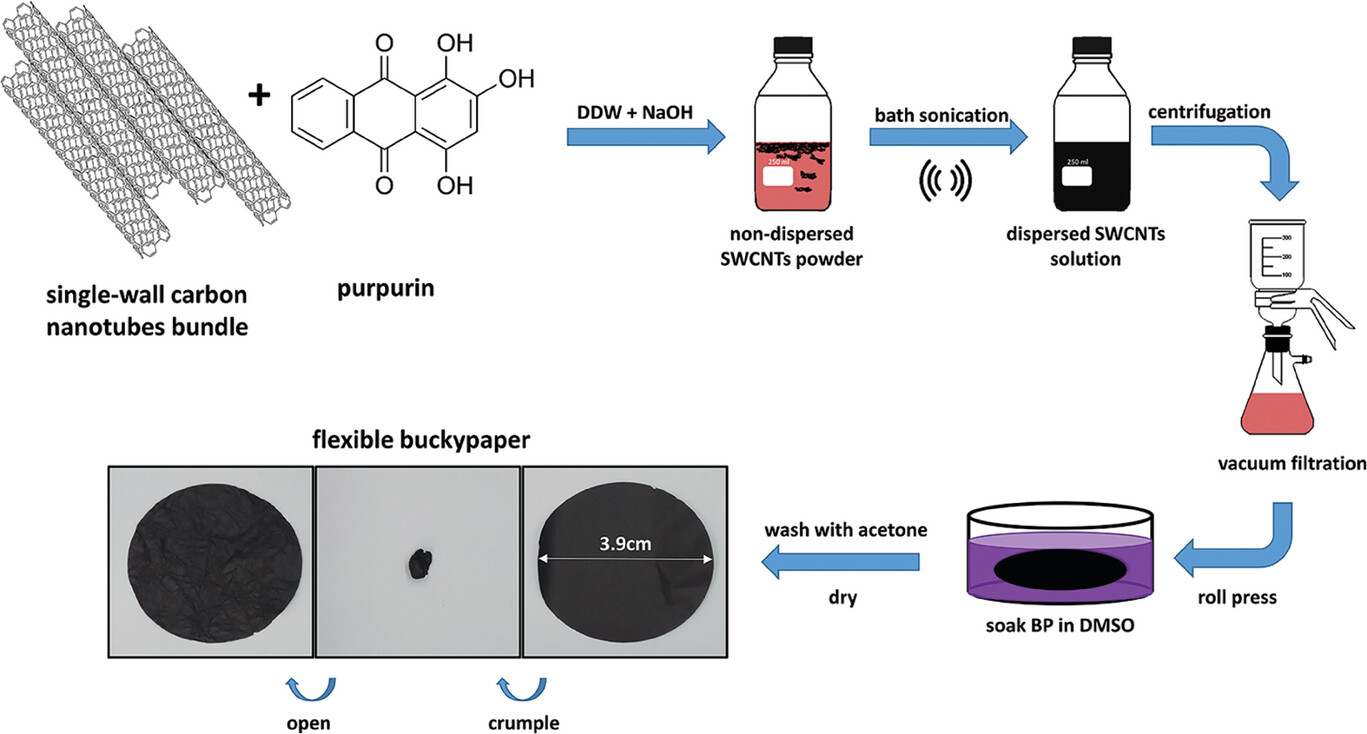

The fabrication strategy of Purpurin-BP. Bundled SWCNTs powder and purpurin (1,2,4-trihydroxyanthraquinone) are added to a fundamental aqueous answer. The answer is then tub sonicated to disperse the SWCNTs, centrifuged, and vacuum filtered to supply a free-standing BP. The BP is then soaked in DMSO to take away extra purpurin. The ultimate product is a versatile BP, which will be crumpled to a ball and restore its unique type with out seen structural harm. (Reprinted with permission from Wiley-VCH Verlag. The vacuum filtration equipment picture was tailored with permission from https://www.jsgw.com/)

By means of obvious robust selective binding and debundling, this strategy yielded SWCNT networks with a 10X increased electrical conductivity of 3726 S/cm together with superior mechanical robustness versus earlier solution-based processing strategies.

The distinctive conductivity increase stems from preferential exfoliation of metallic SWCNTs, creating networks with a far increased metallic tube content material that in flip allows glorious cost transport.

However in contrast to prior makes an attempt with different dyes, purpurin serves as an efficient dispersant whereas largely preserving SWCNT properties. The researchers attribute this to dominant noncovalent interactions arising from the planar dye binding to and serving to solubilize the SWCNTs’ graphitic sidewalls.

Raman spectroscopy revealed modifications indicating enrichment in smaller diameter metallic tubes remaining extremely crystalline with out inducing defects or shifts suggesting cost switch doping that may additionally increase community conductivity however wasn’t as evident right here.

Merely mixing cheap commercially out there SWCNTs and purpurin in fundamental water, tub sonicating and centrifuging the dispersion, then vacuum filtering it onto a membrane produced a versatile “buckypaper” (BP) strip with a benchmark electrical conductivity among the many highest recorded for any CNT materials fabricated through moist processing strategies.

In truth, purpurin-exfoliated SWCNT BPs uniquely mix each distinctive conductivity and mechanical sturdiness, with the latter not often concurrent with the previous. This reveals promise for integrating such solution-based CNT supplies into gadgets relatively than simply conductive composites, whereas their fragility has restricted functions.

By tuning filtration circumstances, the group additionally utilized their dye approach to create clear SWCNT networks exhibiting a wonderful steadiness of excessive transmittance and low sheet resistance rivaling different state-of-the-art carbon nanotube clear conductive movies requiring much more complicated processing.

The simplistic purification-free nature of the developed methodology using cheap, ample elements bodes nicely for enabling scalable manufacturing of enhanced CNT supplies geared for actual industrial advances, versus earlier unique chemistries posing implementation obstacles.

The fabrication strategy of Purpurin-BP. Bundled SWCNTs powder and purpurin (1,2,4-trihydroxyanthraquinone) are added to a fundamental aqueous answer. The answer is then tub sonicated to disperse the SWCNTs, centrifuged, and vacuum filtered to supply a free-standing BP. The BP is then soaked in DMSO to take away extra purpurin. The ultimate product is a versatile BP, which will be crumpled to a ball and restore its unique type with out seen structural harm. (Reprinted with permission from Wiley-VCH Verlag. The vacuum filtration equipment picture was tailored with permission from https://www.jsgw.com/)

By means of obvious robust selective binding and debundling, this strategy yielded SWCNT networks with a 10X increased electrical conductivity of 3726 S/cm together with superior mechanical robustness versus earlier solution-based processing strategies.

The distinctive conductivity increase stems from preferential exfoliation of metallic SWCNTs, creating networks with a far increased metallic tube content material that in flip allows glorious cost transport.

However in contrast to prior makes an attempt with different dyes, purpurin serves as an efficient dispersant whereas largely preserving SWCNT properties. The researchers attribute this to dominant noncovalent interactions arising from the planar dye binding to and serving to solubilize the SWCNTs’ graphitic sidewalls.

Raman spectroscopy revealed modifications indicating enrichment in smaller diameter metallic tubes remaining extremely crystalline with out inducing defects or shifts suggesting cost switch doping that may additionally increase community conductivity however wasn’t as evident right here.

Merely mixing cheap commercially out there SWCNTs and purpurin in fundamental water, tub sonicating and centrifuging the dispersion, then vacuum filtering it onto a membrane produced a versatile “buckypaper” (BP) strip with a benchmark electrical conductivity among the many highest recorded for any CNT materials fabricated through moist processing strategies.

In truth, purpurin-exfoliated SWCNT BPs uniquely mix each distinctive conductivity and mechanical sturdiness, with the latter not often concurrent with the previous. This reveals promise for integrating such solution-based CNT supplies into gadgets relatively than simply conductive composites, whereas their fragility has restricted functions.

By tuning filtration circumstances, the group additionally utilized their dye approach to create clear SWCNT networks exhibiting a wonderful steadiness of excessive transmittance and low sheet resistance rivaling different state-of-the-art carbon nanotube clear conductive movies requiring much more complicated processing.

The simplistic purification-free nature of the developed methodology using cheap, ample elements bodes nicely for enabling scalable manufacturing of enhanced CNT supplies geared for actual industrial advances, versus earlier unique chemistries posing implementation obstacles.

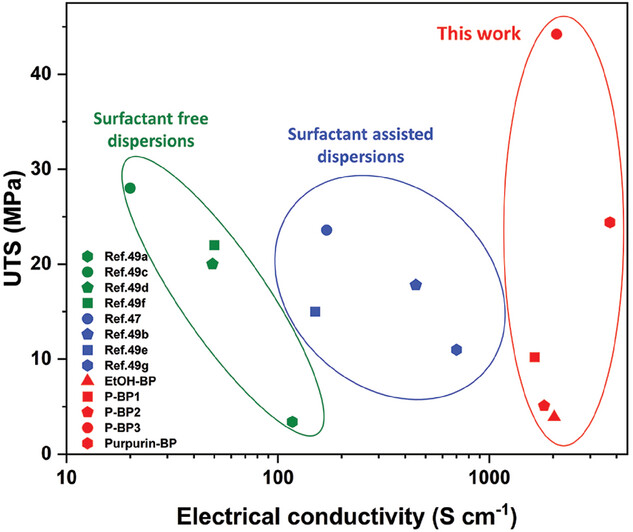

Final tensile energy (UTS, MPa) versus electrical conductivity (S cm−1) of EtOH-BP, Purpurin-BP, P-BPn (n = 1–3), and beforehand reported solution-processed BPs with none post-treatment. Inexperienced: reported BPs fabricated utilizing SWCNT dispersion in natural solvents with out including surfactant. Blue: reported BPs fabricated utilizing SWCNT dispersion in an aqueous answer with the addition of surfactants. Purple: BPs fabricated utilizing SWCNT dispersion in an aqueous answer with the addition of purpurin (this work). (Reprinted with permission from Wiley-VCH Verlag)

Although unable to greatest the conductivity, optical transparency, and mechanical integrity of widespread however more and more problematic indium tin oxide (ITO) layers dominating contact screens and shows, the devised dye tactic notably nudges solution-based SWCNT movies nearer towards feasibly supplanting ITO. In flip, this higher positions SWCNT networks as compelling alternate options to resolve ITO’s infamous brittleness, shortage, and prohibitive price points as show sizes proceed ballooning.

Collectively, these newest insights symbolize a possible breakthrough in unlocking easy, sustainable paths to unlocking carbon nanotubes’ lengthy wanted riches via an innocuous chemical afforded by Mom Nature herself. With swelling industrial curiosity in exploiting CNTs and issues over earlier artificial burdens, economically using non-toxic ambient elements to derive distinctive CNT constructions sparks optimism of lastly realizing their nanotechnological promise.

Final tensile energy (UTS, MPa) versus electrical conductivity (S cm−1) of EtOH-BP, Purpurin-BP, P-BPn (n = 1–3), and beforehand reported solution-processed BPs with none post-treatment. Inexperienced: reported BPs fabricated utilizing SWCNT dispersion in natural solvents with out including surfactant. Blue: reported BPs fabricated utilizing SWCNT dispersion in an aqueous answer with the addition of surfactants. Purple: BPs fabricated utilizing SWCNT dispersion in an aqueous answer with the addition of purpurin (this work). (Reprinted with permission from Wiley-VCH Verlag)

Although unable to greatest the conductivity, optical transparency, and mechanical integrity of widespread however more and more problematic indium tin oxide (ITO) layers dominating contact screens and shows, the devised dye tactic notably nudges solution-based SWCNT movies nearer towards feasibly supplanting ITO. In flip, this higher positions SWCNT networks as compelling alternate options to resolve ITO’s infamous brittleness, shortage, and prohibitive price points as show sizes proceed ballooning.

Collectively, these newest insights symbolize a possible breakthrough in unlocking easy, sustainable paths to unlocking carbon nanotubes’ lengthy wanted riches via an innocuous chemical afforded by Mom Nature herself. With swelling industrial curiosity in exploiting CNTs and issues over earlier artificial burdens, economically using non-toxic ambient elements to derive distinctive CNT constructions sparks optimism of lastly realizing their nanotechnological promise.