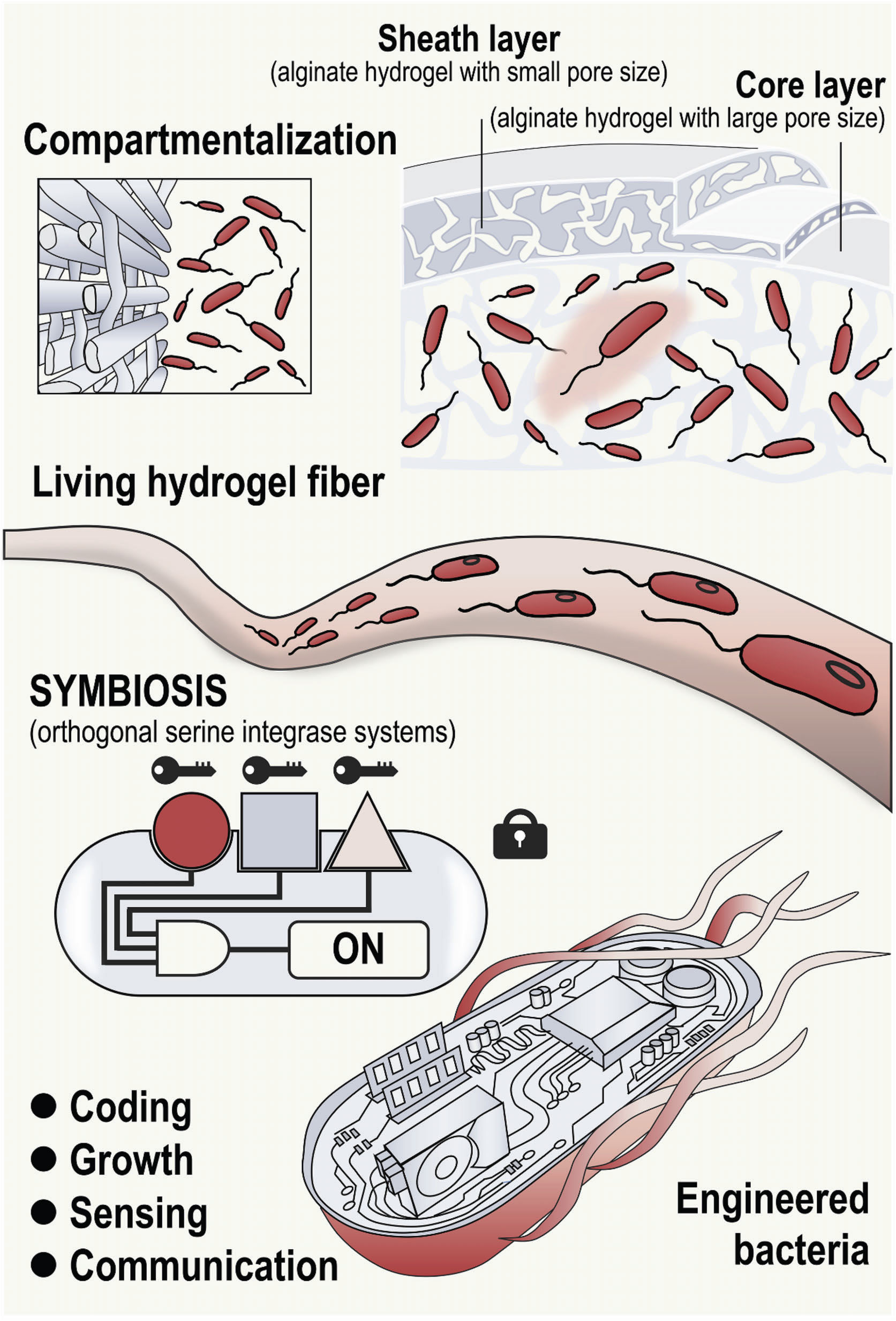

The design of engineered micro organism embedded with mechanically strengthened and functionally programmable hydrogel fiber platform. Hydrogel sheath–core fibers with structural and useful designability have been produced utilizing microfluidic spinning. Engineered micro organism with genetic circuits have been grown inside the pores of the hydrogel fiber core layer, enabling the fibers to exhibit coloration by means of the expression of chromoproteins and fluorescent proteins, and to sense water pollution by expressing fluorescent protein. When mixed with micro organism, the hydrogel fiber develops right into a residing hydrogel fiber (LHF) platform with optimum construction–property–perform. (Reprinted with permission by Wiley-VCH Verlag)

The interior hydrogel core comprises a unfastened polymer community with giant pores facilitating bacterial migration and proliferation. Through the mild room temperature spinning course of, the rod-shaped micro organism align axially inside the core, aiding uniform fiber formation. The researchers additionally utilized a mechanical coaching approach, primarily based on repetitive tensile loading cycles, to considerably reinforce the LHF’s mechanical power and toughness whereas sustaining its tender, versatile nature.

Leveraging artificial biology strategies, the crew then engineered the encapsulated E. coli cells with customizable genetic circuits to develop LHF performance. In a single demonstration, tailor-made plasmids enabled exact expression of various chromoprotein pigments, permitting spun fibers to exhibit a large gamut of persistent colours, together with gradient shifts alongside the size. Weaving the sturdy coloured LHFs into textile architectures created anti-counterfeiting tags.

The dense, microporous outer hydrogel layer features analogously to a permeable cell membrane, permitting diffusion of vitamins and wastes whereas confining the embedded micro organism. This design aspect enhances bacterial progress and concurrently prevents biocontainment points associated to gene-modified organisms escaping into the atmosphere.

In one other software, researchers reconstructed the micro organism to perform as whole-cell biosensors that fluoresce in response to water pollution. The sensitivity and selectivity remained intact after bacterial encapsulation inside the fibers. This allowed fabricating LHF-based units that visually sign contamination ranges in water samples. Collectively, the built-in fiber platform’s mechanical robustness, design versatility, and genetically programmable capabilities set up a flexible toolkit for growing future ELMs.

By emulating pure organic rules, ELMs can doubtlessly remodel materials manufacturing into extra sustainable, resource-efficient practices. As an example, self-growing bacterial cellulose supplies keep away from energy-intensive industrial processes. LHFs develop the chances by providing higher management over ELM construction and properties utilizing present manufacturing strategies, whereas sustaining residing attributes. Wanting ahead, researchers envision ELMs might open new horizons in sensible textiles, bioremediation, regenerative medication, and past. Nonetheless, totally unlocking their potential would require interdisciplinary collaboration crossing conventional boundaries between the life sciences and engineering disciplines.

This pioneering work, marrying sturdy mechanical design with residing attributes, paves the best way for the expansive growth and software of ELMs, providing a tantalizing glimpse into the way forward for materials science.

The design of engineered micro organism embedded with mechanically strengthened and functionally programmable hydrogel fiber platform. Hydrogel sheath–core fibers with structural and useful designability have been produced utilizing microfluidic spinning. Engineered micro organism with genetic circuits have been grown inside the pores of the hydrogel fiber core layer, enabling the fibers to exhibit coloration by means of the expression of chromoproteins and fluorescent proteins, and to sense water pollution by expressing fluorescent protein. When mixed with micro organism, the hydrogel fiber develops right into a residing hydrogel fiber (LHF) platform with optimum construction–property–perform. (Reprinted with permission by Wiley-VCH Verlag)

The interior hydrogel core comprises a unfastened polymer community with giant pores facilitating bacterial migration and proliferation. Through the mild room temperature spinning course of, the rod-shaped micro organism align axially inside the core, aiding uniform fiber formation. The researchers additionally utilized a mechanical coaching approach, primarily based on repetitive tensile loading cycles, to considerably reinforce the LHF’s mechanical power and toughness whereas sustaining its tender, versatile nature.

Leveraging artificial biology strategies, the crew then engineered the encapsulated E. coli cells with customizable genetic circuits to develop LHF performance. In a single demonstration, tailor-made plasmids enabled exact expression of various chromoprotein pigments, permitting spun fibers to exhibit a large gamut of persistent colours, together with gradient shifts alongside the size. Weaving the sturdy coloured LHFs into textile architectures created anti-counterfeiting tags.

The dense, microporous outer hydrogel layer features analogously to a permeable cell membrane, permitting diffusion of vitamins and wastes whereas confining the embedded micro organism. This design aspect enhances bacterial progress and concurrently prevents biocontainment points associated to gene-modified organisms escaping into the atmosphere.

In one other software, researchers reconstructed the micro organism to perform as whole-cell biosensors that fluoresce in response to water pollution. The sensitivity and selectivity remained intact after bacterial encapsulation inside the fibers. This allowed fabricating LHF-based units that visually sign contamination ranges in water samples. Collectively, the built-in fiber platform’s mechanical robustness, design versatility, and genetically programmable capabilities set up a flexible toolkit for growing future ELMs.

By emulating pure organic rules, ELMs can doubtlessly remodel materials manufacturing into extra sustainable, resource-efficient practices. As an example, self-growing bacterial cellulose supplies keep away from energy-intensive industrial processes. LHFs develop the chances by providing higher management over ELM construction and properties utilizing present manufacturing strategies, whereas sustaining residing attributes. Wanting ahead, researchers envision ELMs might open new horizons in sensible textiles, bioremediation, regenerative medication, and past. Nonetheless, totally unlocking their potential would require interdisciplinary collaboration crossing conventional boundaries between the life sciences and engineering disciplines.

This pioneering work, marrying sturdy mechanical design with residing attributes, paves the best way for the expansive growth and software of ELMs, providing a tantalizing glimpse into the way forward for materials science.

By

Michael

Berger

– Michael is creator of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Know-how,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Abilities and Instruments Making Know-how Invisible

Copyright ©

Nanowerk LLC

Turn into a Highlight visitor creator! Be a part of our giant and rising group of visitor contributors. Have you ever simply printed a scientific paper or produce other thrilling developments to share with the nanotechnology neighborhood? Right here is publish on nanowerk.com.