Projection micro stereolithography (PμSL) has emerged as a robust three-dimensional (3D) printing method for manufacturing polymer buildings with micron-scale excessive decision at excessive printing velocity, which permits the manufacturing of personalized 3D microlattices with function sizes right down to a number of microns. Nevertheless, the mechanical properties of as-printed polymers weren’t systemically studied on the related size scales, particularly when the function sizes step into micron/sub-micron degree, limiting its dependable efficiency prediction in micro/nanolattice and different metamaterial functions.

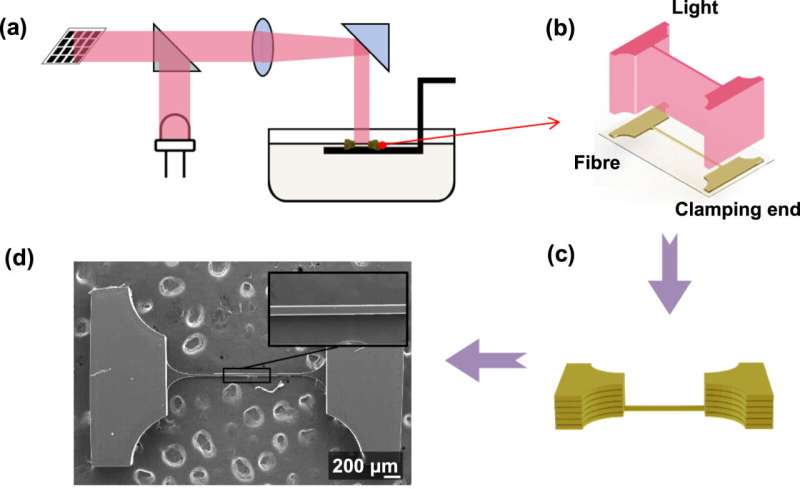

Primarily based on self-developed in situ micro-mechanical platform, Prof. Yang Lu from Metropolis College of Hong Kong demonstrates that projection micro-stereolithography (PμSL)-printed microfibers might change into stronger and considerably extra ductile with lowered dimension starting from 20 μm to 60 μm, displaying an apparent size-dependent mechanical conduct, through which the dimensions decreases to twenty μm with a fracture pressure as much as ~100% and fracture energy as much as ~100 MPa.

Such dimension impact permits the tailoring of the fabric energy and stiffness of PμSL-printed microlattices over a broad vary, permitting to manufacture the microlattice metamaterials with desired/tunable mechanical properties for varied structural and practical functions.

Incorporating the dimensions impact of the PμSL printed polymer permits us to acquire microlattice with completely different mechanical properties but the identical topography and relative density. The modulus of the microlattice with 20 μm is measured to be ~87 MPa about twice in contrast with that of the lattice with struts diameter of 60 μm (~43 MPa). After the lattices had been yielded, the stress of the lattice with 20 μm struts elevated with the pressure. This can be attributed to the pressure hardening part of the micro-sized struts. Whereas the lattice with a diameter of 60 μm reveals typical stress curves of brittle supplies.

This outcome reminds us to contemplate the dimensions of the polymer when designing microlattice metamaterials. Such size-dependent mechanical conduct of PμSL-printed acrylate-based resin buildings permits the tailoring of the fabric energy and stiffness of microlattice items over a variety, enabling the rational fabrication of microlattice scaffolds with desired/programmable mechanical properties for the event of novel micro/nano-lattice mechanical metamaterials.

“These days, vat photopolymerization 3D printing applied sciences, akin to PµSL, can present a wonderful mixture of ultrahigh printing decision and enormous printing dimension, paving the paths for geometrically complicated elements with well-defined hierarchical buildings for structural and practical metamaterials,” explains Professor Lu Yang within the Division of Mechanical Engineering, who led this analysis.

“A deep understanding of the mechanical properties of PμSL-printed polymer at small size scales will speed up the event of superior mechanical metamaterials akin to micro/nanolattice supplies with unprecedent efficiency. Dimension-dependent mechanical properties of supplies has been all the time the central focus of my group’s analysis. It additionally conjures up us to pay extra consideration to make the most of such dimension results for designing superior mechanical metamaterials with crucial options steps into micro/nanoscales.”

The analysis was printed within the Worldwide Journal of Excessive Manufacturing.

Wenqiang Zhang et al, Tailoring mechanical properties of PμSL 3D-printed buildings by way of dimension impact, Worldwide Journal of Excessive Manufacturing (2022). DOI: 10.1088/2631-7990/ac93c2

Supplied by

Worldwide Journal of Excessive Manufacturing

Quotation:

Creating stronger and extra ductile microlattice supplies with lowered unit sizes (2022, October 14)

retrieved 16 October 2022

from https://phys.org/information/2022-10-stronger-ductile-microlattice-materials-sizes.html

This doc is topic to copyright. Aside from any truthful dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for info functions solely.