Analytics expertise has significantly disrupted the manufacturing business over the past decade. In line with Mordor Intelligence, the marketplace for analytics in manufacturing will probably be value $19.5 billion by 2028.

There are a variety of ways in which analytics has helped manufacturing firms enhance their backside line. We’ve got identified that it may well perfect for forecasting future demand and get a greater understanding of market developments in one in every of our articles on utilizing analytics for bettering advertising and marketing in manufacturing.

Nonetheless, there are loads of different main advantages of utilizing analytics to optimize the enterprise fashions of producing companies. One of many main benefits of analytics is that it may well assist manufacturing firms produce items extra successfully, extra shortly and with fewer defects.

That is very true in the case of creating the exoskeletons of robots. We alluded to this profit in our article Spend money on Analytics to Enhance Your Manufacturing Line. Preserve studying to find out how this course of is altering in mild of advances in analytics.

Designing and machining exoskeleton robotic wants loads of machining experience, now a days with the appearance of recent machining applied sciences designing and creating extra exact exoskeleton robots is sort of simple. These machining methods allow the engineers to determine the right materials consideration and structural stability of the robots. With the assistance of recent machining instruments engineers are engaged on designing advanced and extremely efficient designs that improve human mobility, power augmentation, and useful versatility.

Fashionable machining methods reminiscent of 3-D printing and 5-axis CNC machining, assist engineers and designers to create advanced geometries. These superior machining innovation helps in creating light-weight constructions, that enhance the agility of the robots. Additional on this article, we are going to clarify the position and superb improvements of utilizing superior machining processes in several elements of creating exoskeleton robots.

Machining Challenges in Prototyping and Iterative Design

Growing a prototype that meets the performance necessities is a fancy activity. Lots of repetition and design alterations are wanted to determine an ideal design that meets all of the useful and structural necessities. In standard machining practices, the prototyping stage may cause a extreme headache to you. It’s a incontrovertible fact that dealing with the machining challenges is an integral facet of designing and creating this exoskeleton equipment. Happily, analytics helps considerably.

For engineers and designers attaining excessive precision and tight tolerance is crucial paramount. The sort of equipment usually consists of small and complicated intricate elements, these elements require excessive precision to make sure optimum efficiency. To realize this excessive precision engineers have to do some iterative changes to refine the design based mostly on efficiency suggestions.

Superior CNC machining and 3D-printing expertise helps rather a lot in gaining design alterations and provides an opportunity to check completely different supplies and designs. The principle motive of engineers is to develop a structural body that’s light-weight and has sturdy structural power. On this perspective, engineers have to check completely different supplies and discover optimum combos for power, weight, and sturdiness.

The implementation of those superior machining methods helps in creating exoskeleton robots which have excessive performance, structural sturdiness, affected person adaptability, and consumer consolation on this quickly advancing subject.

Tolerance Administration in Machining for Exoskeleton Joint Mechanisms

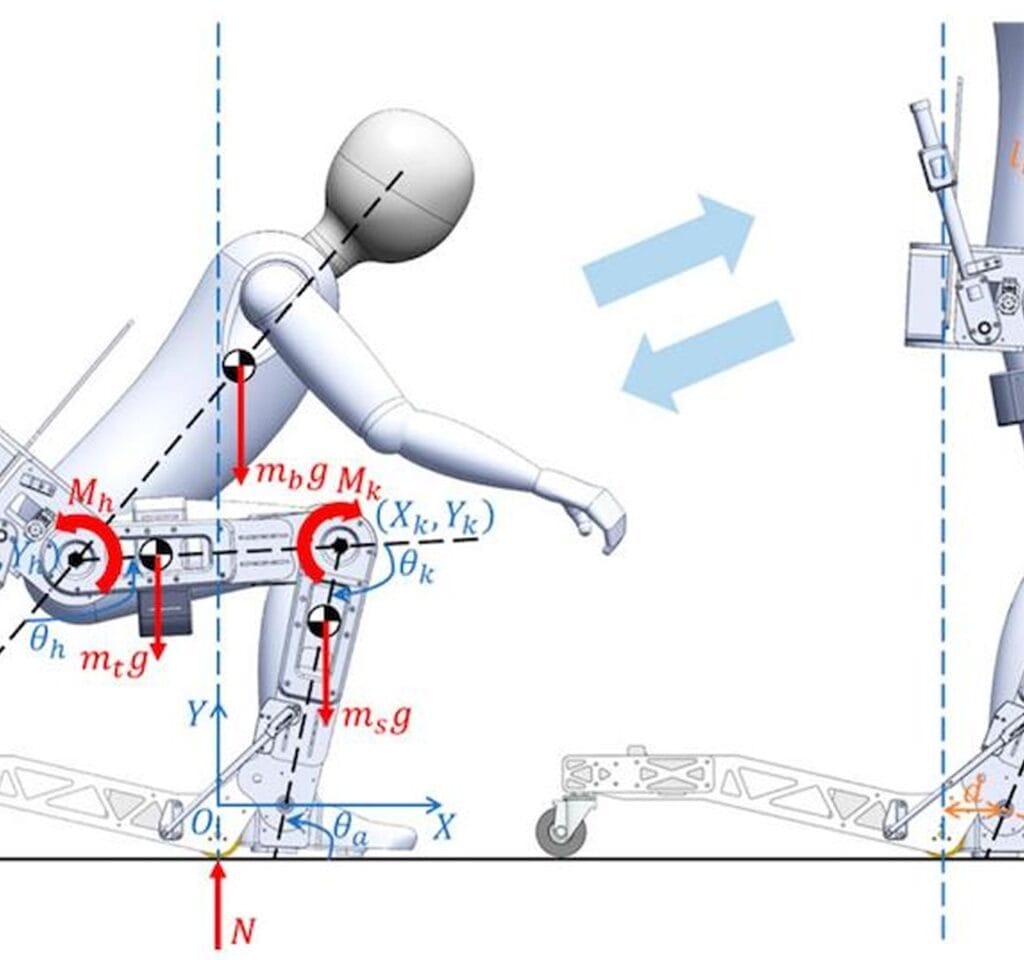

The fundamental function of the exoskeleton construction is to develop equipment that may help consumer’s every day physique actions and improve their way of life. This paramount can solely be achieved if the producers guarantee tight tolerance within the exoskeleton joint mechanism. Tolerance administration is an important facet for making certain dependable performance in exoskeleton equipment in order that it facilitates pure human actions. CNC machining is a primary participant in it, this excessive degree of precision can solely be achieved by superior laptop numerical management machining.

For a greater understanding of the significance of tolerance in intricate joints, let’s take into account the instance of the Decrease Rib Hip Exoskeleton. The exoskeleton is the hip joint construction of the human physique, the hip joint consists of a ball and socket interface and it permits flexion, extension, abduction, and adduction. As a result of weight of the physique, the hip joint wants loads of structural stability. This joint wants a decent tolerance and it may well solely be achieved by the CNC machining. CNC machining together with CAD modeling permits an ideal design for the socket a part of the joint for optimum efficiency.

Now for the ball part of this joint mechanism, which is desired to articulate inside the socket. For a easy movement inside the socket construction, the ball must be completely exact and the tolerance needs to be minimal. The CNC machining permits to fabricate of an ideal ball part as per the specified tolerances as tight as a couple of micrometers. And for the socket, which will probably be machined to reflect, these tolerances will probably be a comfortable match that minimizes any play within the joint.

On this means, tolerance administration in exoskeleton machining is carried out in order that engineers can guarantee an ideal biomechanical construction, that assists the consumer with good ergonomic design.

Machining Integration for Sensor-Embedded Exoskeleton

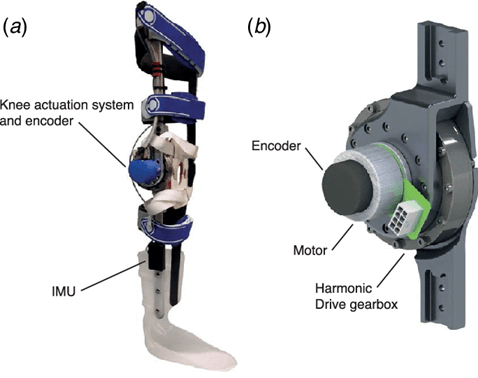

Sensor and adaptive suggestions techniques are essential elements for enhancing performance and efficiency in exoskeleton robots. The correct studying by these sensors permits the designers to maintain enhancing the biomechanical construction of those robots. The sensor system together with a management unit wants a desired particular area for its set up and means within the robotic for wiring or suggestions system. The Precision machining methods enable to create of correct housing together with intricate pathways. These pathways guarantee tidy and environment friendly integration of sensors.

For a greater understanding of machining challenges in these robots, exemplify the installment of stress embedded system in exoskeletons. The stress sensors are positioned beneath the toes to guage the movement of the physique. For higher suggestions from these sensors they have to be positioned in such a means in order that they can learn even a slight motion and it’ll solely be attainable if they’re distributed evenly. For that purpose an intricate pathway is created by CNC machining which reinforces the exoskeleton’s responsiveness to consumer motion.

In sensor embedded exoskeletons one other vital facet is protecting layers. The sensors and the management unit is very delicate to environmental circumstances, they could be broken or begin giving unsuitable studying to regulate items in the event that they get humidified. For that purpose, protecting layers are manufactured by the assistance of advance precision machining, principally by multi axis machines in order that they guarantee easy operations in sensors. These protecting layers are comprised of aluminum and polymer alloys and machined as per particular form of the joints.

Floor Ending for Enhanced Put on Resistance

Because the exoskeleton robots encompass loads of intricate joined elements, principally these elements are ball and pin joints. It’s a incontrovertible fact that these sort of joints beneath a number of load bearings circumstances usually face put on and friction points. If these points are available in these robots, they trigger lag of their movement.

To beat these points, an acceptable coating and floor remedy method is used to reinforce the agility and lifespan of those equipment. A number of ending methods like Bodily Vapor Deposition, Chemical Vapor Deposition, Sharpening and precision machining contribute to eliminating these points. Mirror-finish sharpening, which is achieved by precision machining and abrasive course of helps in decreasing floor irregularities.

Conclusion

Summing issues up, the machining methods play a pivotal position in sustaining the biomechanical form of the exoskeleton robots. The methods assist to take care of tight tolerance between joints and exact actions of the exoskeleton elements in order that they’ll guarantee ergonomic actions as per human nature. The machining methods carried out on exoskeletons want knowledgeable engineers and designers for machining its advanced elements so one needs to be effectively conscious of the machining functionality of the chosen machining store.