Information briefs for the week check out the return of PACK EXPO Worldwide after its 4-year COVID-caused hiatus from the tradeshow circuit. The producers promised a big-bang reentry, and so they delivered, calling it One Highly effective Present. From the angle of robots and cobots, nevertheless, it was a dominating efficiency. From what was in proof on the present ground, evermore dominance in robot-driven automation is coming within the very close to future.

One present, two takeaways!

Upon hitting the present ground, the jump-out realizations to seize onto at Pack Expo 2022 are two: Extra cobots doing extra issues higher and extra flexibly than ever; after which, upon nearer inspection of those self same cobots, the truth that integration of cobot techniques is the  subsequent nice advance in robotics. If that’s all you took away from the present, you’d have, in a nutshell, seen the way forward for packaging and packing.

subsequent nice advance in robotics. If that’s all you took away from the present, you’d have, in a nutshell, seen the way forward for packaging and packing.

The editors for the present’s producer PMMI (The Affiliation for Packaging and Processing Applied sciences (previously Packaging Equipment Producers Institute)), observed the cobot inhabitants enhance proper off, as they walked the ground to report on their first impressions.

“Collaborative robots, or cobots, are growing their affect on packaging techniques. It was once that robots on the present ground needed to be given a large berth. It’s nonetheless a little bit stunning to see these cobots freed from any enclosure, the place attendees are free to work together with them.”

Inside these two realizations exists a world of selection, flexibility, and built-in “intelligence.” Wonderful is the seepage of robotics into almost each side of packaging, packing, and manufacturing.

KUKA, ABB & Beckhoff

KUKA’s Chad Dukart, confirmed off one such integration with KUKA’s Decide Management system that makes use of “good” imaginative and prescient software program to  concurrently management the actions of a 6-axis cobot, two Delta robots and a SCARA robotic all working the identical conveyor line selecting and packing product in what he referred to as, “robot-based software program for conveyor monitoring with built-in picture processing.”

concurrently management the actions of a 6-axis cobot, two Delta robots and a SCARA robotic all working the identical conveyor line selecting and packing product in what he referred to as, “robot-based software program for conveyor monitoring with built-in picture processing.”

With product cycles getting shorter and shorter, whereas useful resource and vitality effectivity are receiving ever larger consideration, versatile, built-in manufacturing options are in demand. He mentioned that he may, for instance, with the contact of a button, have one or the opposite Delta robots work sooner or slower, and nonetheless the conveyors stuffed with product to be packed would stay in sync.

ABB showcased a normal IRB 360 FlexPicker that displayed one other new cobot talent in selecting integration: synthetic intelligence “that  permits the robotic to study and adapt to all kinds of things together with cuboids, cylinders, pouches, blisters, and random shapes, as present in electronics, pharma, healthcare, cosmetics and different client product industries.”

permits the robotic to study and adapt to all kinds of things together with cuboids, cylinders, pouches, blisters, and random shapes, as present in electronics, pharma, healthcare, cosmetics and different client product industries.”

ABB claims that the FlexPicker’s internally developed AI resolution offers unprecedented accuracy with a “first-time, right-pick fee of 98.5%, and selecting effectivity of >99.5 %,” in selecting gadgets from unstructured surroundings; and due to lowered computing time, “peak choose charges of as much as 1,500 gadgets per hour.”

In what was harking back to snap-together toys, Beckhoff confirmed up with ATRO, a modular industrial “snap-together” cobot system “that can be utilized to assemble the optimum cobot constructions for various purposes on a person and versatile foundation.”

Want a 4-axis cobot at the moment, a 6-axis cobot tomorrow, and perhaps a seventh axis thrown in simply in case? Effectively, the ATRO (Automation Expertise for Robotics) system is comprised of standardized motor modules with built-in drive performance, and hyperlink modules of assorted designs and lengths.

Want a 4-axis cobot at the moment, a 6-axis cobot tomorrow, and perhaps a seventh axis thrown in simply in case? Effectively, the ATRO (Automation Expertise for Robotics) system is comprised of standardized motor modules with built-in drive performance, and hyperlink modules of assorted designs and lengths.

Beckhoff says that each one ATRO modules “function an inside media feed for information, energy, and fluids (vacuum, air, and water). This permits ATRO to make use of a wide range of instruments, similar to mechanical, pneumatic, or electrical grippers. As a result of these media feeds are inside, it permits for infinite rotation of ATRO axes and finish effector instruments, as there are not any exterior cables to hinder the robotic’s vary of movement.”

Epson companions with itself!

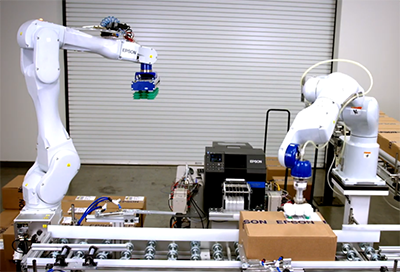

In case you are Epson and recognized for colour printers, you might be additionally recognized for cobots. Out of a novel partnering between Epson’s cobots and  printers sprang a novel, new option to print labels after which affix them to packages as they journey alongside a conveyor.

printers sprang a novel, new option to print labels after which affix them to packages as they journey alongside a conveyor.

That’s the concept behind Epson showcasing its VT6L All-in-One 6-Axis robotic with built-in controller paired with the Epson ColorWorks C6000 Collection colour inkjet label printer.

It’s additionally a terrific instance of the flexibility in design and functionality that cobots are bringing to automation, particularly at Pack Expo the place all the flexibility may be seen and skilled inside strolling distance from one to the opposite on the expo ground.

Epson will also be credited with one other distinctive, world’s first, with its adaptation of 6-axis design cobot with a “folding” arm kinematic configuration (see picture).

Nice for working in tight areas, the compact arm of the Flexion has the power to fold by way of itself, versus transferring round itself. Epson claims that it makes use of 40% much less house than a normal 6-axis arm and may simply work inside an envelope of 1 sq. meter, which is right for space-constrained medical and pharma labs.

Cobots tackle the mighty delivery pallet

The common-or-garden however mighty picket delivery pallet (48 in × 40 in or 1,219 mm × 1,016 mm), with over 2 billion in use worldwide, has been the worldwide transport commonplace for close to one-hundred years. The modest pallet is so highly effective a delivery medium that it’s been elevated  to verb standing: therefore, to palletize; and its reverse, to depalletize.

to verb standing: therefore, to palletize; and its reverse, to depalletize.

All method of human and software program calculations have been devised on how finest to pack pallets after which to stabilize their hundreds for secure, environment friendly, and least expensive transport. People charged with loading pallets is pure, brain-numbing drudgery…and costly, however, as a rule, people get the job, if, that’s, sufficient people may be discovered to rent.

Automating palletizing and depalletizing can be an trade dream come true. Caged-off robots do it most frequently, however in out-of-the-way delivery areas distant from folks and remoted from the move of manufacturing.

Cobots are the most recent to tackle the problem of automating the packing of the mighty delivery pallet. Pack Expo even had a Logistics Pavilion with 25 aspiring packing/packaging firms, with some seeking to tackle the problem.

To win the palletizing/depalletizing problem is to have a extremely cell, go-anywhere-in-factory-or-warehouse cobot that might work amid people and regular manufacturing flows, work lengthy hours at close to most payload, shortly pack out a pallet, after which be nimble sufficient to maneuver on to the following pallet in a rush.

To win the palletizing/depalletizing problem is to have a extremely cell, go-anywhere-in-factory-or-warehouse cobot that might work amid people and regular manufacturing flows, work lengthy hours at close to most payload, shortly pack out a pallet, after which be nimble sufficient to maneuver on to the following pallet in a rush.

Two partnered as much as tackle the world championship of palletizing: World chief in cobot gross sales, Denmark’s Common Robots (UR), toting alongside its latest 6-axis cobot, the UR20, with its 20kg payload capability and longest attain, along with its accomplice, Canada’s Robotiq, a specialist palletizing purposes and options.

All of it went down in sales space N-4925.

And wouldn’t you recognize, they pulled it off in grand fashion!

And wouldn’t you recognize, they pulled it off in grand fashion!

Packaging World reported: “The prolonged attain functionality of the UR20 is demonstrated within the Robotiq palletizing system, because it reveals how the UR20 can be utilized to stack gadgets to a peak of 1800mm (5.9 toes). With its prolonged attain, the UR20 can be utilized to stack throughout two commonplace U.S. pallets. With Euro pallets, the UR20 can stack as much as 2m in peak.”

In the end, the mighty delivery pallet has met its match, and it’s a cobot! A cobot vendor’s machine built-in with Robotiq’s software proved decisive.

The UR/Robotiq partnership typified the 2 distinctive takeaways of Pack Expo: Cobots married to integration is the following huge factor.

Remember to search for it at a tradeshow or occasion close to you.

.png#keepProtocol)