Challenges and alternatives for connecting manufacturing tools

ALMiG (or Automated Air Pumps, Automatische Luftpumpen) Group, an industrial air compressor producer situated in Germany is utilizing 5G Low Energy Vast Space (LPWA) applied sciences NB-IoT and LTE-M to attach each new and legacy machines with minimal funding. The intention is to attach machines to cloud analytic platforms within the easiest way doable utilizing a low-cost connectivity answer that may assist all units. By integrating Modbus Cloud Join into their merchandise, ALMiG has been in a position to enrich their COMPASS (Compressed Air Service Answer) digital companies with actual IoT-data.

Problem

The primary problem was to develop new capabilities and enterprise fashions for tools that was already in service, and in a brief timeframe with out prolonged customized {hardware} improvement. The IoT answer adopted wanted to be versatile sufficient to be each retrofitted to current machines and likewise fitted to new machines. In the meantime, ALMiG needed to work with a scarcity of actual information concerning the utilization of their machines within the subject. A further problem was the complexity of the IoT ecosystem, with totally different companions and suppliers probably offering totally different parts and a possible dependence on end-user prospects for information communications infrastructure.

Answer

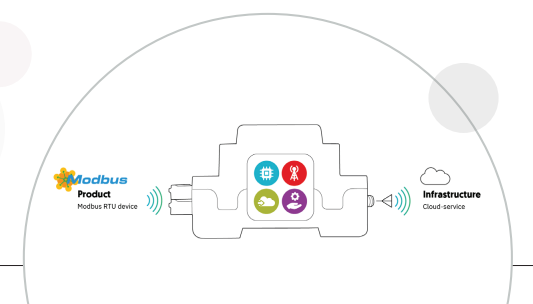

ALMiG chosen the Modbus Cloud Join product provided by grandcentrix (a Vodafone firm) to attach each new and already deployed (‘brownfield’) air compressors. Modbus Cloud Join builds the digital bridge and connection between the sensing and actuat[1]ing Modbus RTU (distant terminal unit) units contained in the air compressors and the cloud infrastructure of ALMiG.

Impression and statistics

The brand new answer permits ALMiG to supply new enterprise fashions, together with ‘as-a-service’ propositions utilizing actual time IoT information. Clients profit from every day updates, immediate notification of vital standing updates, and improved up-time via preventive upkeep. One other key profit lies in ALMiG’s potential to make use of IoT information from actual world deployments to reinforce future product improvement.

Wider implications

Vast space 5G LPWA (NB-IoT and LTE-M) related productised options are well-suited to IoT enabling industrial tools in an economical approach and specifically can play a big position within the context of brownfield tools. Such options may be simple to implement, environment friendly, sustainable, and inexpensive for each the producer and its prospects. Retrofit IoT options can allow producers to supply new companies related to current machines which can be already deployed at shopper websites, and likewise to make these machines way more environment friendly. As with many IoT options, retrofitting tools helps to optimise operational processes via distant monitoring and reduces the chance of apparatus failure utilizing predictive upkeep to unlock additional price financial savings.

Challenges and alternatives for connecting manufacturing tools

In an intensely aggressive setting, tools distributors should undertake the newest applied sciences to allow vanguard companies and stay aggressive. Ideally such companies would embody all tools that’s utilized by their prospects together with each new tools offered and likewise tools that has been in service at shopper places probably for a few years. However the customers of such tools usually can’t afford any downtime and changing legacy machines and tools with new sensible units and instruments is pricey. Accordingly, distributors of producing tools will place a premium on ‘sensible’ options that may be built-in into each new and legacy (‘brownfield’) belongings.

ALMiG Group is a provider of air compressors which can be used as a part of many alternative manufacturing processes. The corporate has discovered an modern method to join each new air compressors and their current units property with a single answer through the use of 5G Low Energy Vast Space (LPWA) applied sciences NB-IoT and LTE-M to attach current Modbus management and actuation capabilities. In collaboration with grandcentrix (a Vodafone firm) ALMiG was in a position to quickly develop a related answer by making use of grandcentrix’s Modbus Cloud Join product.

By integrating Modbus Cloud Join into their tools, ALMiG digitised their merchandise and higher enabled their new COMPASS (Compressed Air Service Answer) service utilizing real-time IoT-data. The central cloud software program related to the COMPASS service will preserve a digital twin of any related machine and allows the processing, analysis, and storage of knowledge. Accessible information can be utilized to reinforce current processes and likewise to assist new propositions comparable to, for instance, enhanced servitised fashions. Utilizing grandcentrix {hardware} and working on Vodafone’s mobile communications platform each current and legacy units may be related utilizing standardised {hardware} and pre-configured cloud adaptors.

grandcentrix’ Modbus Cloud Join product has 4 key points:

- {Hardware}: Modbus Cloud Join Gateway is CE licensed {hardware} with onboard firmware developed by grandcentrix, a kind issue for DIN rail mounting and together with terminal connections. The system has metallic and non-metallic floor antennas to help connectivity.

- Connectivity: Features a pre-installed SIM chipset that permits connection to 5G LPWA (NB-IoT and LTE-M) networks supported with a easy cellular connectivity tariff.

- Self-Service-Portal: A portal for system administration and pre-configured data-integration through cloud-adap.

- Assist: Preliminary assist for system onboarding, in addition to steady assist for ongoing operations together with a service desk and hassle ticket system.

The advantages of related manufacturing tools

Within the case of ALMiG, the Modbus Cloud Join product was notably useful because the firm already operated a cloud platform and was in a position to comparatively simply add new companies based mostly on the brand new IoT information. Because the adoption of Modbus Cloud Join, ALMiG has launched a second cloud platform to allow a subsequent technology of digital companies.

The brand new IoT information helps key points of ALMiG’s newly launched COMPASS proposition, together with supporting prospects with every day updates, immediate notification of vital standing updates, and improved uptime via preventive upkeep. General, the inclusion of IoT information has enabled ALMiG emigrate from offering reactive assist to offering proactive assist.

This method contains points comparable to information administration the place purchasers typically lack information science capabilities and may profit from assist to outline required information constructions, frequencies of replace, and which information feeds and correlations must be tracked to achieve essentially the most perception. Moreover, ALMiG has been in a position to simplify service actions and supply new companies that stretch to cowl all plant-related actions.

Macro stage info offered to purchasers features a dashboard together with each particular person system information and likewise information a few purchasers’ worldwide ALMiG system property.

One other key profit lies in ALMiG’s potential to make use of IoT information from actual world deployments to reinforce future product improvement. Traditionally, ALMiG has provided compressors to a number of industries, however with little information or suggestions concern[1]ing precisely how the units had been being utilized by totally different buyer segments. Within the medium time period, the corporate expects to have the ability to optimise product specs for various buyer varieties in order that options that aren’t required may be omitted and compressor capabilities may be higher matched to buyer wants. Such an method will allow ALMiG to make their total compressor portfolio extra aggressive in an evolving market.

From an operational perspective, ALMiG advantages from the power to undertake pre-emptive upkeep and improve their total method to subject servicing. Presently, when massive compressors break down, subject engineers should typically fly to a buyer location to undertake the required repairs. Accordingly, the place repairs may be undertaken pre-emptively as part of routine service upkeep there are important advantages when it comes to journey time and expense. Moreover, there are important sustainability advantages related to decreasing air journey.

Potential to scale back price and involvement of a number of third-party sources

One of many challenges confronted by ALMiG is that its purchasers sometimes purchase machines for big factories and industrial crops involving important investments and corresponding depreciation durations of a few years.

Accordingly, it will be important for ALMiG to cater to buyer demand for clear and immediate entry to utilization information sourced from sensible and related machines, while additionally enabling these prospects to maximise their return on earlier investments by enabling comparable companies on already deployed machines.

For ALMiG, the deployment of Modbus Cloud Join was an efficient method to join each new and current machines and to optimise companies related to each. Utilizing Modbus Cloud Join, compressors may be remotely monitored and managed to scale back on-site operational effort utilizing current sensors and actuators. The answer may be simply retrofitted into current machines and legacy programs and may be related via pre-configured cloud adapters and use of the 5G cellular communications.

5G LPWA applied sciences NB-IoT and LTE-M mixed with established Modbus protocols allows flexibility, simplicity and ease in deployment

5G LPWA applied sciences NB-IoT and LTE-M had been notably essential for ALMiG since compressors are usually situated indoors and infrequently in areas which can be troublesome to succeed in with broad space mobile connectivity applied sciences apart from NB-IoT and LTE-M. In the meantime, the advantages of offering direct connections to compressors are manifold, since such connections don’t depend on any third-party infrastructure apart from a mobile community (which is in flip contracted to, and underneath the management of, ALMiG). In distinction, if ALMiG had adopted a short-range connectivity answer then connectivity for every compressor would have relied on a buyer’s native community and likewise ALMiG getting access to that community in order that compressors could possibly be remotely managed. Accordingly, using 5G applied sciences allows ALMiG to manage direct connections to finish units, whereas an answer based mostly on short-range applied sciences must depend on a particularly fragmented property of native shopper networks. In flip, using 5G permits ALMiG to decide to ship sure service ranges, because the firm controls all related infrastructure end-to-end.

Advantages of the Modbus Cloud Join answer adopted by ALMiG embody:

- Flexibility: Together with the potential to assist each the retrofit of current items within the subject and the equipping of latest items with current electronics, no matter unit varieties or collection. This permits ALMiG to show a buyer’s whole property of compressors into sensible merchandise.

- Simplicity: Through the use of 5G LPWA applied sciences NB-IoT and LTE-M, information communication turns into impartial of third-party infrastructure and there are clearly outlined interfaces. This permits simple connection into current Modbus-enabled capabilities of units and helps assortment of actual time information comparable to working hours and circumstances and allows units to be managed remotely (as an example by adjusting air stress settings). Connection to cloud infrastructure permits initiatives to be scaled shortly.

- Ease in deployment: One other key characteristic is that because the Modbus Cloud Join answer is productised it may be deployed with none requirement for or dependence on any exterior third occasion vendor other than grandcentrix. Effort, threat and prices that may end result from the coordination and integration of exterior events are thus considerably decreased.

Extending the rollout and enabling a brand new business proposition

The partnership between ALMiG and grandcentrix shall be continued and even expanded. Presently there are discussions concerning the improvement of a further cloud-platform to enrich the present cloud platform. Within the mid and long-term the goal is to develop new functions and new companies for patrons.

The partnership between ALMiG and grandcentrix shall be continued and even expanded. Presently there are discussions concerning the improvement of a further cloud-platform to enrich the present cloud platform. Within the mid and long-term the goal is to develop new functions and new companies for patrons.

Utilizing the big variety of information factors that are actually sourced from compressors, ALMiG is working with information science specialists from grandcentrix to get new insights into buyer utilization of the tools, ensuing within the improvement of latest functions or options. For instance, customised and usage-based notifications may be offered to prospects. Furthermore, these insights shall be mirrored in AMiG’s product portfolio improvement and R&D.

Modbus Cloud Join by Vodafone/grandcentrix makes IoT merely simple.

Modbus Cloud Join is the “all-in-one” IoT product for direct connection of Modbus RTU units through LPWA (Narrowband-IoT & LTE-M) to the cloud. For extra info, please go to: https://grandcentrix.internet/ en/merchandise/modbus/

grandcentrix is a 100%-subsidiary of Vodafone Germany, supporting enterprises with the profitable implementation of IoT initiatives. This contains customized bespoke IoT options (skilled companies) in addition to IoT plug&play merchandise comparable to Modbus Cloud Join. In each enterprise pillars the main focus is on the connection of units to the web of issues with experience alongside all IoT disciplines, from embedded engineering, manufacturing and certification, cloud backend and frontend, app, safety and information science.