(Nanowerk Information) Built-in optical sign distributing, processing, and sensing networks require the miniaturization of fundamental optical components, corresponding to waveguides, splitters, gratings, and optical switches. To attain this, fabrication approaches that enable for high-resolution manufacturing are required. Curved components like bends and ring resonators are particularly difficult to manufacture, as they want even increased decision and decrease sidewall roughness. Moreover, fabrication strategies with exact management of absolute construction dimensions are crucial.

A number of applied sciences have been developed for subwavelength high-resolution manufacturing, corresponding to direct laser writing, multi-photon lithography, electron beam lithography, ion beam lithography, and domino lithography. Nevertheless, these applied sciences are pricey, complicated, and time-consuming. Nanoimprint lithography is an rising replication approach well-suited for high-resolution and environment friendly manufacturing. Nevertheless, it requires high-quality grasp stamps, that are normally produced utilizing electron beam lithography.

In a brand new paper printed in Gentle: Superior Manufacturing (“Function measurement under 100 nm realized by UV-LED-based microscope projection photolithography”), scientists Dr.-Ing. Lei Zheng et al. from the Leibniz College Hannover have developed a low-cost and user-friendly fabrication approach, referred to as UV-LED-based microscope projection photolithography (MPP), for speedy high-resolution manufacturing of optical components inside seconds. This strategy transfers construction patterns on a photomask to a photoresist-coated substrate beneath UV illumination.

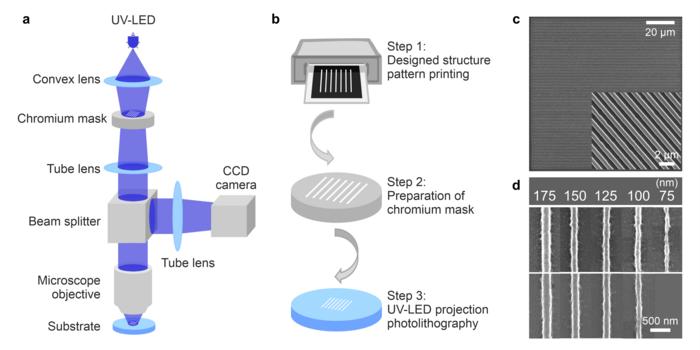

a Sketch of the employed UV-LED-based microscope projection photolithography system. b Schematic illustration of course of chain together with steps from construction design to the ultimate projection lithography. c Excessive-resolution gratings fabricated utilizing MPP. d Function sizes under 200 nm achieved by MPP. The strains proven within the higher half and decrease half had been fabricated utilizing a pricey goal and an financial goal, respectively. (Picture: Lei Zheng, Tobias Birr, Urs Zywietz, Carsten Reinhardt and Bernhard Roth)

The MPP system relies on customary optical and optomechanical components. As an alternative of a mercury lamp or a laser, a particularly low-cost UV-LED with a wavelength of 365 nm is used as the sunshine supply.

The researchers developed a previous course of to acquire the structure-patterned chromium masks required in MPP. It contains construction design, printing on a clear foil, and the sample switch onto the chromium photomask. They established a lithography setup for the preparation of photomasks as effectively. Construction patterns printed on the clear foil might be transferred to a chromium photomask with this setup and a subsequent wet-etching course of.

The MPP system can fabricate high-resolution optical components with function sizes all the way down to 85 nm. That is corresponding to the decision of far more costly and complicated fabrication strategies, corresponding to multi-photon and electron beam lithography. MPP may very well be used to manufacture microfluidic units, biosensors, and different optical units.

This fabrication strategy developed by the researchers is a major development within the discipline of lithography for the speedy and high-resolution structuring of optical components. It’s significantly well-suited for purposes the place speedy prototyping and low-cost fabrication are necessary. For instance, it may very well be used to develop new optical units for biomedical analysis or to prototype new MEMS units for client electronics purposes.

a Sketch of the employed UV-LED-based microscope projection photolithography system. b Schematic illustration of course of chain together with steps from construction design to the ultimate projection lithography. c Excessive-resolution gratings fabricated utilizing MPP. d Function sizes under 200 nm achieved by MPP. The strains proven within the higher half and decrease half had been fabricated utilizing a pricey goal and an financial goal, respectively. (Picture: Lei Zheng, Tobias Birr, Urs Zywietz, Carsten Reinhardt and Bernhard Roth)

The MPP system relies on customary optical and optomechanical components. As an alternative of a mercury lamp or a laser, a particularly low-cost UV-LED with a wavelength of 365 nm is used as the sunshine supply.

The researchers developed a previous course of to acquire the structure-patterned chromium masks required in MPP. It contains construction design, printing on a clear foil, and the sample switch onto the chromium photomask. They established a lithography setup for the preparation of photomasks as effectively. Construction patterns printed on the clear foil might be transferred to a chromium photomask with this setup and a subsequent wet-etching course of.

The MPP system can fabricate high-resolution optical components with function sizes all the way down to 85 nm. That is corresponding to the decision of far more costly and complicated fabrication strategies, corresponding to multi-photon and electron beam lithography. MPP may very well be used to manufacture microfluidic units, biosensors, and different optical units.

This fabrication strategy developed by the researchers is a major development within the discipline of lithography for the speedy and high-resolution structuring of optical components. It’s significantly well-suited for purposes the place speedy prototyping and low-cost fabrication are necessary. For instance, it may very well be used to develop new optical units for biomedical analysis or to prototype new MEMS units for client electronics purposes.