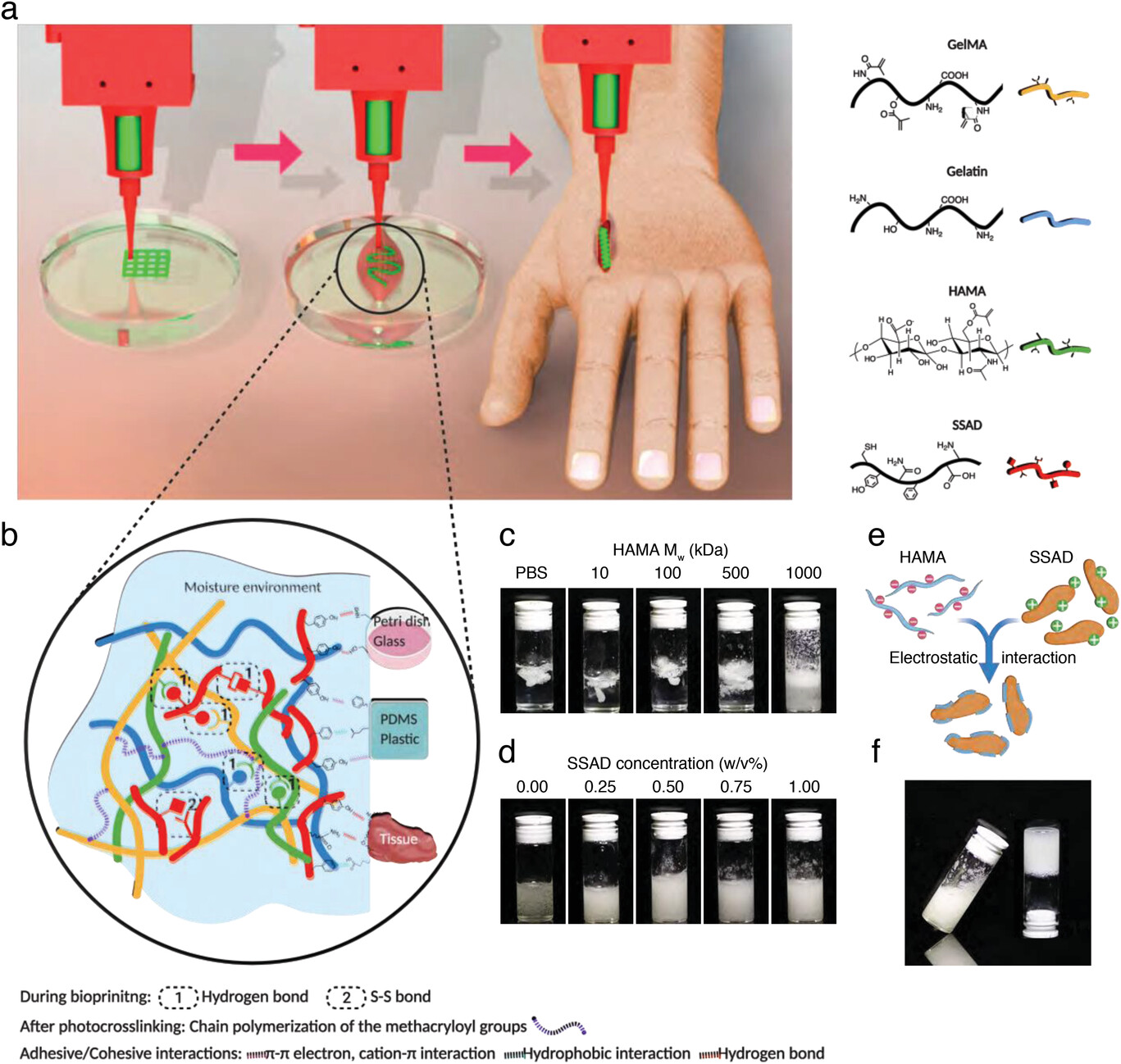

Illustrations of extrusion bioprinting beneath moist situations and the composition of the adhesive/cohesive bioink. a) A diagram of the bioprinting course of, together with bioprinting in moist situations, testing in vitro, and in situ bioprinting. b) The interactions throughout the bioink embody primarily S–S bond and hydrogen bonds, which contributes to the bioink cohesiveness. The chain polymerization of GelMA and HAMA after photocrosslinking additional introduces secure chemical bonds. The adhesive mechanisms embody π-π electron, cation–π interplay, hydrophobic interactions, hydrogen bonds, in addition to steel coordination bonds between the deposited bioink and totally different substrates, together with tissue culture-treated petri dish, glass, PDMS, plastic (pristine polystyrene), and organic tissues. c) SSAD distribution in HAMA options with totally different Mw beneath the identical focus (1.0 w/v%). d) SSAD distribution in HAMA (Mw = 1000 kDa) options with totally different SSAD concentrations. e) Schematic displaying negatively charged HAMA neutralizing positively charged SSAD via electrostatic interactions. f) {Photograph} of the chosen bioink with well-distributed SSAD. (Reprinted with permission by Wiley-VCH Verlag)

The examine particulars an adhesive bioink containing gelatin methacryloyl (GelMA), gelatin, methacrylated hyaluronic acid (HAMA), and a pure bioadhesive polymer from frog pores and skin secretions. Whereas earlier bioinks lacked robust interlayer and floor bonding in moist environments like surgical settings, this new ink shows versatile adhesion and excessive form constancy when printed on various tissues, implants, and different surfaces.

Recreating advanced dwelling constructions requires printing a number of supplies and cell sorts into intricate 3D architectures. Nevertheless, commonplace bioinks typically disintegrate when printed underwater. This presents obstacles for rising strategies like intraoperative bioprinting, the place tissue grafts are straight printed into wound websites throughout surgical procedure. The analysis crew got down to formulate a wet-adhesive ink to deal with this drawback.

They discovered that integrating frog pores and skin secretions with GelMA, gelatin, and HAMA produced an ink with enhanced cohesive and adhesive properties. GelMA types the photocrosslinkable scaffold, whereas gelatin Offers area for cell migration. HAMA helps disperse the frog pores and skin particles for optimum adhesive results.

By means of electrostatic and hydrophobic interactions, HAMA’s detrimental cost stabilizes the constructive cost of the bioadhesive frog pores and skin secretions. This prevents particle clumping and evenly distributes adhesiveness. Collectively, hydrogen bonding amongst all elements permits glorious ink move and form retention when extruded underwater.

The ink shows shear-thinning viscosity superb for bioprinting, quickly solidifying after extrusion. Lap shear adhesion power reaches as much as 17 kPa on porcine pores and skin with moist surfaces—over twice as excessive as management bioinks. Importantly, robust adhesion happens on many tissues and supplies like glass, plastic, and silicone beneath moist situations.

Utilizing a personalized bioprinting system, the researchers showcased multi-interface printing of subtle 2D and 3D architectures underwater. Sample constancy stays unchanged in numerous media like cell tradition medium, demonstrating versatility. To reinforce precision, maneuverability and entry for surgical procedure, they built-in the bioink with handheld bioprinting instruments.

Complicated flat and 3D constructs had been efficiently printed in situ onto ex vivo porcine pores and skin utilizing totally different ergonomic nozzles. Encapsulated NIH/3T3 fibroblasts exhibit over 95% viability instantly after moist printing, proliferating over 5 days of tradition. In rats, subcutaneous hydrogel implants show sustained structural integrity and biocompatibility over 4 weeks.

Lastly, the bioink’s speedy gelation and tissue adhesion enabled efficient hemostasis in liver wounds. Utilized to bleeding incisions in rats, the ink rapidly stopped blood loss in comparison with each business fibrin glue and untreated controls.

With robust moist adhesion, excessive biocompatibility, and adaptable fluid properties, this new bioink method exhibits immense promise. Handheld bioprinting could now allow intricate tissue grafts to be printed and cling straight throughout surgical procedure. The expertise might additionally produce tissue patches, bandages, and hemostatic merchandise.

Ongoing challenges embody vascularizing thicker printed tissues and stopping postoperative graft detachment as a result of motion. Integrating managed drug launch could assist improve cell survival and integration. Nonetheless, this adhesive ink ought to open new horizons for bioprinting in regenerative medication and wound remedy.

Illustrations of extrusion bioprinting beneath moist situations and the composition of the adhesive/cohesive bioink. a) A diagram of the bioprinting course of, together with bioprinting in moist situations, testing in vitro, and in situ bioprinting. b) The interactions throughout the bioink embody primarily S–S bond and hydrogen bonds, which contributes to the bioink cohesiveness. The chain polymerization of GelMA and HAMA after photocrosslinking additional introduces secure chemical bonds. The adhesive mechanisms embody π-π electron, cation–π interplay, hydrophobic interactions, hydrogen bonds, in addition to steel coordination bonds between the deposited bioink and totally different substrates, together with tissue culture-treated petri dish, glass, PDMS, plastic (pristine polystyrene), and organic tissues. c) SSAD distribution in HAMA options with totally different Mw beneath the identical focus (1.0 w/v%). d) SSAD distribution in HAMA (Mw = 1000 kDa) options with totally different SSAD concentrations. e) Schematic displaying negatively charged HAMA neutralizing positively charged SSAD via electrostatic interactions. f) {Photograph} of the chosen bioink with well-distributed SSAD. (Reprinted with permission by Wiley-VCH Verlag)

The examine particulars an adhesive bioink containing gelatin methacryloyl (GelMA), gelatin, methacrylated hyaluronic acid (HAMA), and a pure bioadhesive polymer from frog pores and skin secretions. Whereas earlier bioinks lacked robust interlayer and floor bonding in moist environments like surgical settings, this new ink shows versatile adhesion and excessive form constancy when printed on various tissues, implants, and different surfaces.

Recreating advanced dwelling constructions requires printing a number of supplies and cell sorts into intricate 3D architectures. Nevertheless, commonplace bioinks typically disintegrate when printed underwater. This presents obstacles for rising strategies like intraoperative bioprinting, the place tissue grafts are straight printed into wound websites throughout surgical procedure. The analysis crew got down to formulate a wet-adhesive ink to deal with this drawback.

They discovered that integrating frog pores and skin secretions with GelMA, gelatin, and HAMA produced an ink with enhanced cohesive and adhesive properties. GelMA types the photocrosslinkable scaffold, whereas gelatin Offers area for cell migration. HAMA helps disperse the frog pores and skin particles for optimum adhesive results.

By means of electrostatic and hydrophobic interactions, HAMA’s detrimental cost stabilizes the constructive cost of the bioadhesive frog pores and skin secretions. This prevents particle clumping and evenly distributes adhesiveness. Collectively, hydrogen bonding amongst all elements permits glorious ink move and form retention when extruded underwater.

The ink shows shear-thinning viscosity superb for bioprinting, quickly solidifying after extrusion. Lap shear adhesion power reaches as much as 17 kPa on porcine pores and skin with moist surfaces—over twice as excessive as management bioinks. Importantly, robust adhesion happens on many tissues and supplies like glass, plastic, and silicone beneath moist situations.

Utilizing a personalized bioprinting system, the researchers showcased multi-interface printing of subtle 2D and 3D architectures underwater. Sample constancy stays unchanged in numerous media like cell tradition medium, demonstrating versatility. To reinforce precision, maneuverability and entry for surgical procedure, they built-in the bioink with handheld bioprinting instruments.

Complicated flat and 3D constructs had been efficiently printed in situ onto ex vivo porcine pores and skin utilizing totally different ergonomic nozzles. Encapsulated NIH/3T3 fibroblasts exhibit over 95% viability instantly after moist printing, proliferating over 5 days of tradition. In rats, subcutaneous hydrogel implants show sustained structural integrity and biocompatibility over 4 weeks.

Lastly, the bioink’s speedy gelation and tissue adhesion enabled efficient hemostasis in liver wounds. Utilized to bleeding incisions in rats, the ink rapidly stopped blood loss in comparison with each business fibrin glue and untreated controls.

With robust moist adhesion, excessive biocompatibility, and adaptable fluid properties, this new bioink method exhibits immense promise. Handheld bioprinting could now allow intricate tissue grafts to be printed and cling straight throughout surgical procedure. The expertise might additionally produce tissue patches, bandages, and hemostatic merchandise.

Ongoing challenges embody vascularizing thicker printed tissues and stopping postoperative graft detachment as a result of motion. Integrating managed drug launch could assist improve cell survival and integration. Nonetheless, this adhesive ink ought to open new horizons for bioprinting in regenerative medication and wound remedy.

By

Michael

Berger

– Michael is writer of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Know-how,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Expertise and Instruments Making Know-how Invisible

Copyright ©

Nanowerk LLC

Grow to be a Highlight visitor writer! Be a part of our massive and rising group of visitor contributors. Have you ever simply revealed a scientific paper or produce other thrilling developments to share with the nanotechnology neighborhood? Right here is methods to publish on nanowerk.com.