| Dec 15, 2023 |

|

|

|

(Nanowerk Information) Nature boasts an unparalleled expertise for materials fabrication by means of exact molecular structure – the intricate protein machines that drive metabolism and replication reveal Meeting traces fine-tuned over eons of evolution. Regardless of exceptional advances, chemists nonetheless wrestle to method the precision and complexity of even the humblest biomolecule. Nonetheless, current breakthroughs inch nearer towards custom-engineering artificial supplies from the molecular up.

|

|

New polymerization strategies afford unprecedented management to dictate properties by means of designed sequences alongside polymer backbones – but functions of such Sequence-defined macromolecules stay confined to area of interest domains like knowledge encryption.

|

|

New analysis, printed in Small (“Macromolecular Engineering: From Exact Macromolecular Inks to 3D Printed Microstructures”), pioneers sequence management right into a transformative manufacturing paradigm – additive 3D microprinting.

|

|

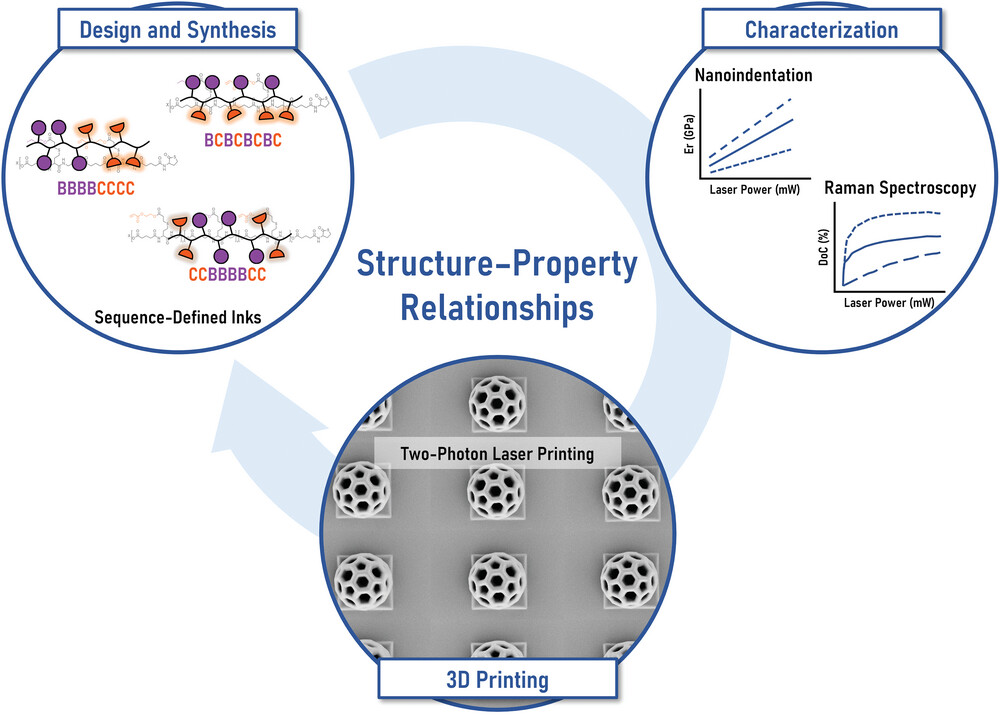

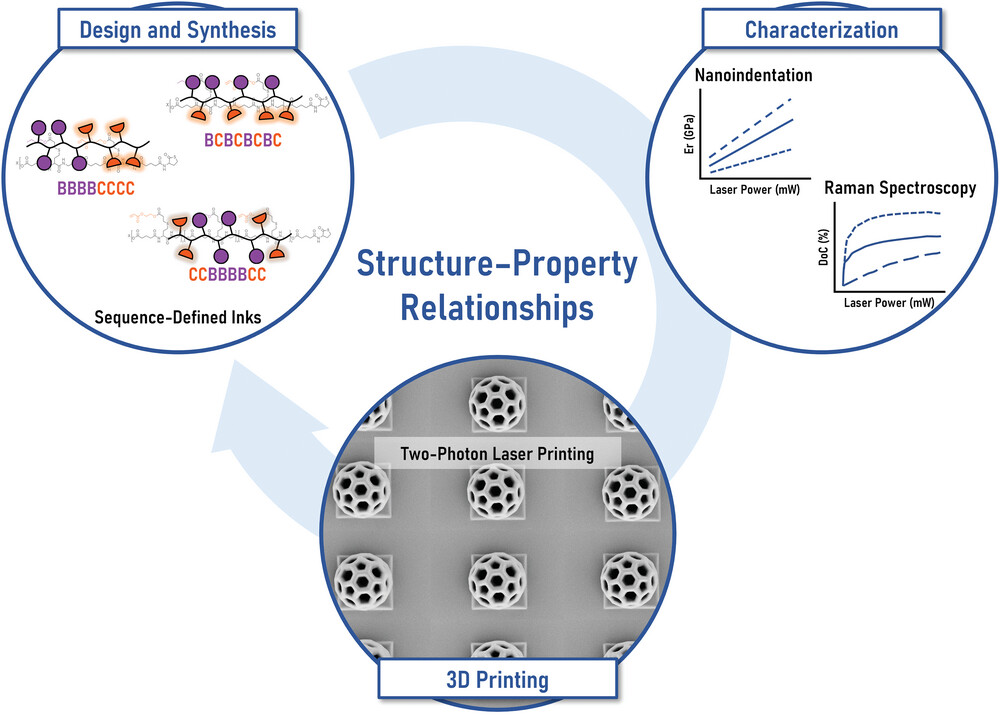

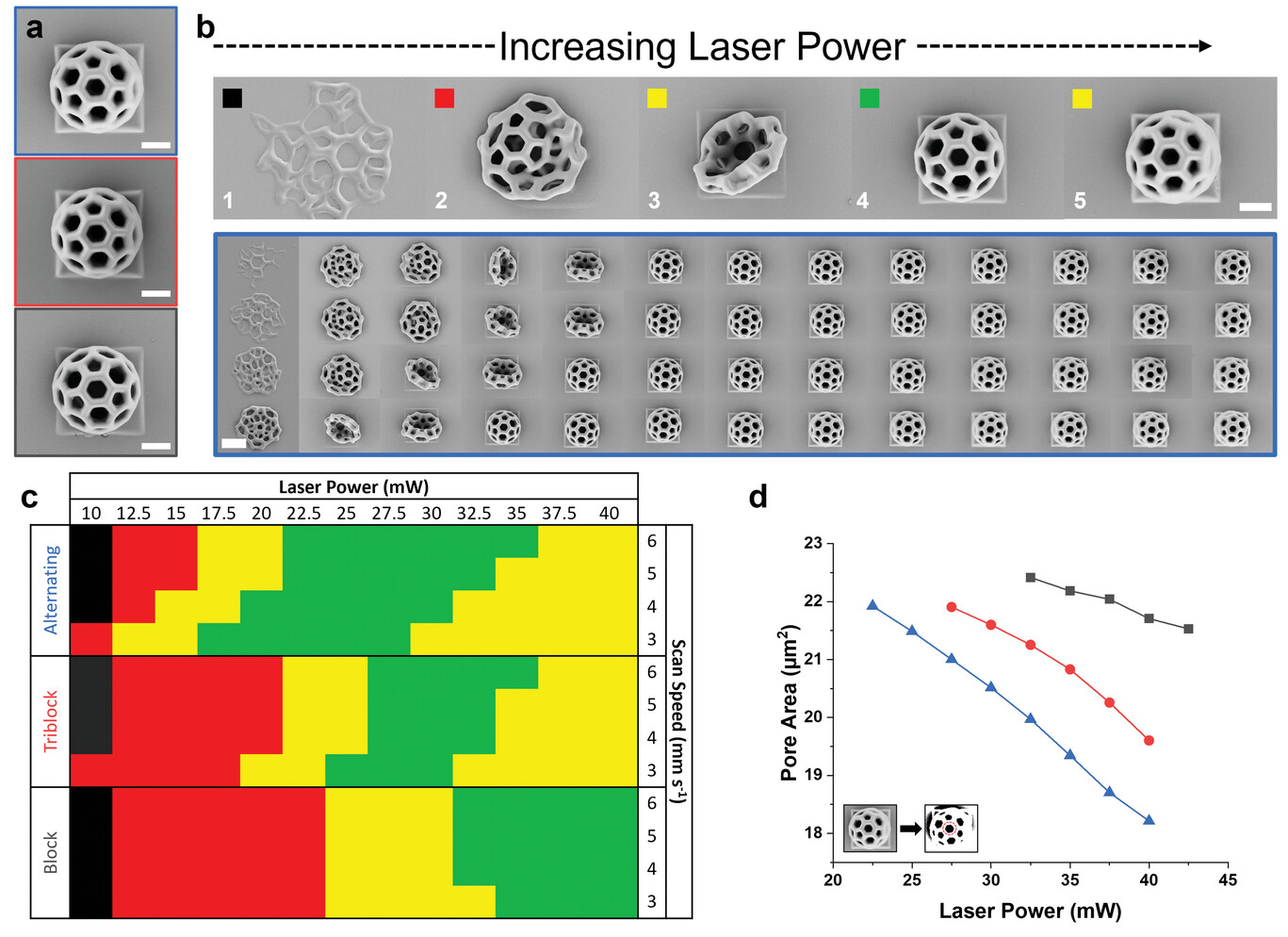

| Overview and relationship of the steps explored within the following work: design and synthesis of the three crosslinkable oligomers with managed monomer sequence, 2PLP of 3D microstructures from the formulated inks, chemical and mechanical characterization of the 3D microstructures, and the relationships from macromolecular management to printed microstructures. (Reprinted with permission from Wiley-VCH Verlag)

|

|

By means of rational molecular design, the analysis workforce from Heidelberg College and the Max Planck Institute for Medical Analysis, direct sequence-defined supplies as 3D printable inks, programming print decision, mechanics and fabrication limits from monomer positioning alongside the first construction. Such molecular mastery unlocks huge potential for 3D developing specialised gadgets, from focused drug supply automobiles to labeled cell development scaffolding and even molecular circuit elements. As nature has proven, sequence encodes perform.

|

|

This new analysis bridges sequence-defined macromolecules with 3D microprinting to pioneer a brand new era of intricately structured supplies.

|

|

Two-photon laser printing (2PLP) allows fabrication of micro-scale 3D buildings like micro-optics or microrobotics. Nonetheless, standard acrylate inks lack molecular definition. This analysis investigates manipulates macromolecular sequence to systematically alter 3D printability and properties.

|

|

The researchers synthesized three distinctive eight-unit oligomers with similar composition however diverse positioning of photocross-linkable and non-functional items. The oligomers contained both alternating crosslinkable/non-functional teams, a crosslinkable triblock motif bracketed by non-functional items, or a non-functional block bracketing crosslinkable teams.

|

|

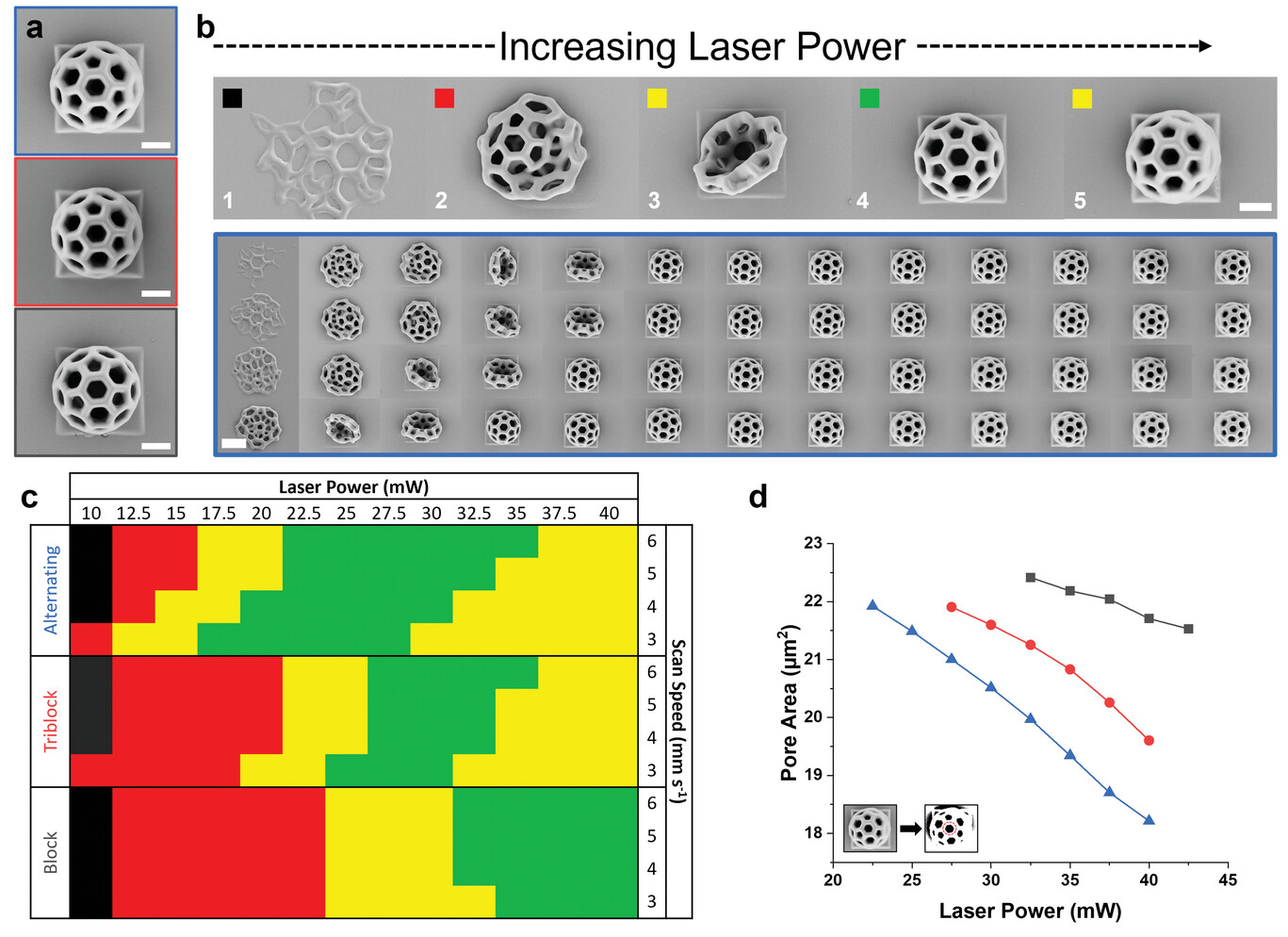

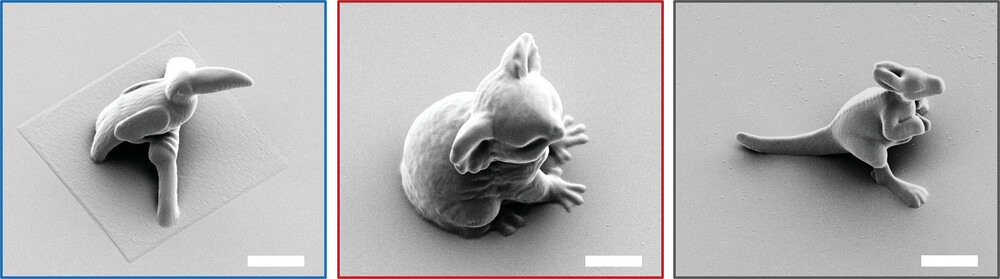

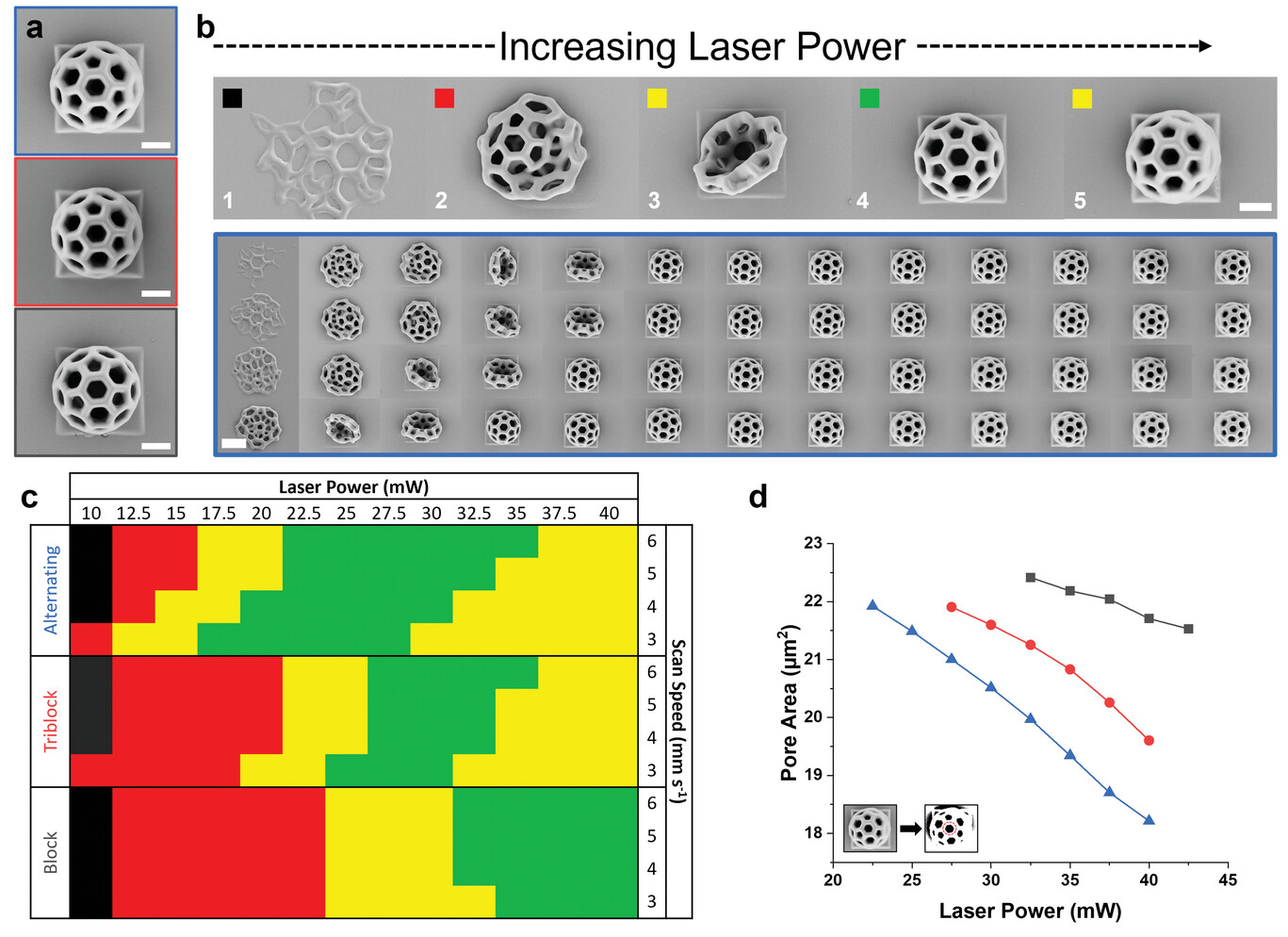

After formulating inks, the workforce 3D printed intricate “buckyball” buildings, analyzing print decision throughout diverse laser parameters. Surprisingly, the alternating oligomer afforded the widest printing window earlier than defects occurred, requiring the bottom gentle depth but reaching the best mechanical integrity of the three inks.

|

|

| a) 2PLP printed 3D buckyball buildings utilizing alternating (blue), triblock (purple), and block (grey) oligomer inks (laser energy = 32.5 mW, scan velocity 5 mm s−1), b) SEM photographs of the printability examine at growing laser powers for alternating ink, from 10 mW to 40 mW (left to proper) and from 3 to six mm s−1 (backside to prime). c) Printability of the three oligomer inks over laser energy vary 10–40 mW and scan speeds of three–6 mm s−1. d) Evaluation of reducing space of the central pore with growing laser energy, after changing the microscope photographs to binary. Insert of (d) reveals consultant SEM picture (left) and binary picture (proper) with the analyzed space highlighted in purple. Scale = 8 µm. (Reprinted with permission from Wiley-VCH Verlag)

|

|

By means of spectroscopic monitoring throughout printing, the researchers traced enhanced efficiency to variations in crosslinking kinetics and community topology dictated by sequence. Crosslink positioning modified native response charges and alternatives. Block positioning concentrated reactive teams, driving fast conversion but low mechanical properties, doubtlessly from intramolecular loops leaving dangling chains. Alternating placement dispersed teams for gradual homogeneous community formation with out defects, maximizing mechanics. Triblock printing fell intermediate.

|

|

Various crosslink proximity additionally altered necessities for print stability. The block oligomer, regardless of highest conversion, wanted far larger gentle intensities to print with out collapsing, hinting localized weak point from uneven topology. Sequence can instantly program print efficiency by means of programmed community improvement.

|

|

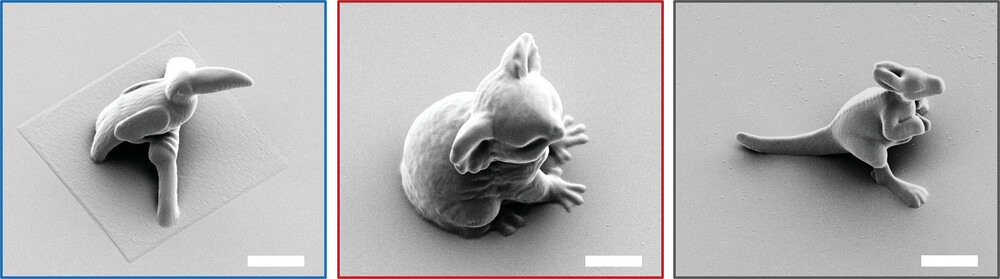

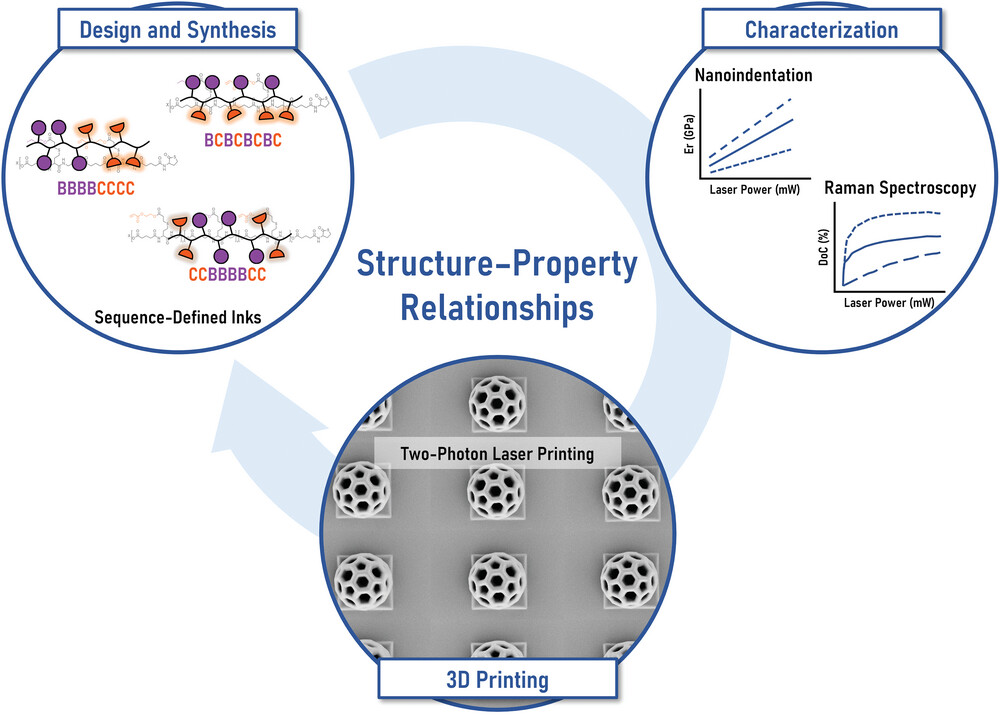

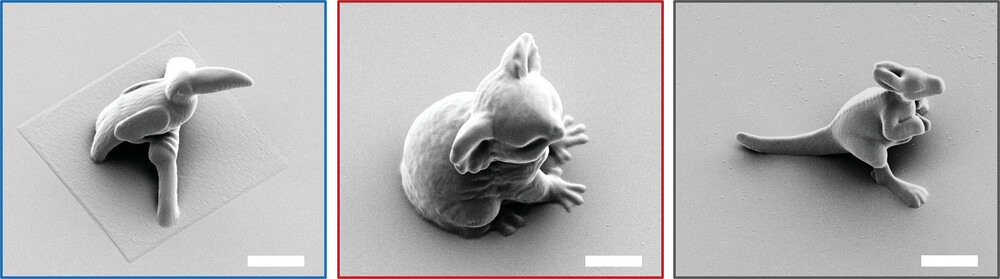

With beautiful sequence-based management to dictate print behaviors, the researchers then demonstrated microprinting intricately structured birds, mammals and crops throughout the three inks. The alternating oligomer achieved the best decision and overhangs. Just lately developed photoinitiators promise even larger capacities.

|

|

| Consultant SEM photographs of 3D microstructures printed with 2PLP with alternating (blue), triblock (purple), and block (grey) oligomer inks printed with 0.25 wt.% DETC demonstrating versatility of the oligomers as inks for 3D microprinting. Scale = 10 µm. (Reprinted with permission from Wiley-VCH Verlag)

|

|

This pioneering analysis illuminates how sequence-defined molecular engineering can unlock immense potentials for 3D printing personalized supplies. Just by manipulating the positioning of photocrosslinkable items alongside an oligomer spine, the researchers programmed dramatic variations in print decision, fabrication home windows, mechanics and topology of finalized prints. The examine supplies a framework and molecular-level understanding to translate precision synthesis into 3D prints rivaling organic builds.

|

|

The doorways now opened to custom-tailor 3D printable inks by means of sequence design are huge and intriguing. Past dialing mechanical energy, flexibility and dynamics through monomer positioning, one may additionally engineer specialised prints from the molecular up – drug-releasing vessels with encoded launch kinetics, development elements to spur directed cell migration, conductive stacks for recording neuronal indicators or labeled scaffolding to check stem cell forces throughout division.

|

|

Such exact and multi-functional 3D printed architectures may speed up gadget fabrication from prosthetics to lab-on-a-chip and bio-integrated electronics. Simply as nature’s proteins obtain wondrous range and precision of perform by means of programmed sequencing of amino acids, this breakthrough guarantees a brand new period the place human-designed sequencing of macromolecules could lastly method such wonders.

|