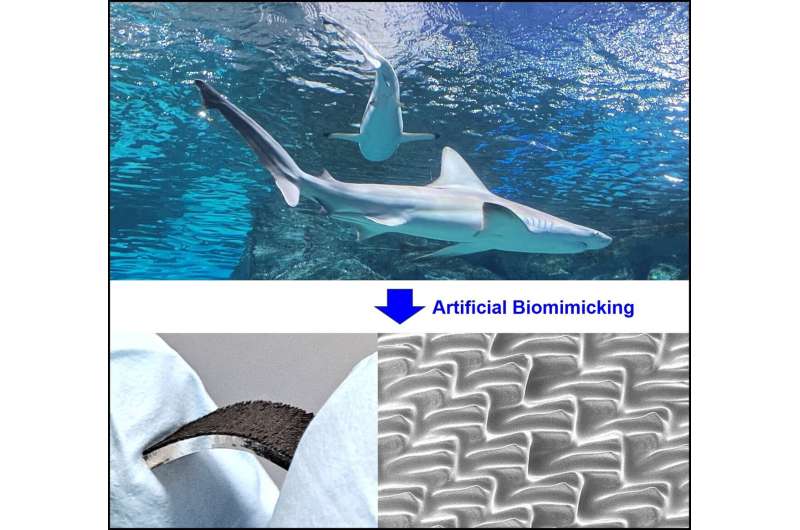

Sharks in nature swim at excessive speeds in a deep ocean attributable to their excessive drag discount skill. Water flows across the sharkskin turn out to be disrupted by staggered and overlapping microscale constructions named denticles. Along with this floor roughness, water slips at a fluid-solid interface with a number of groove-like microriblets on particular person microdenticles.

Moreover, the sharkskin reveals excessive penetration resistance due to its quad-layered construction from enamel to dermis. There are hard-on-soft layered mechanical gradients from the skin to the within of the sharkskin.

This distinctive and practical sharkskin present in nature motivates this examine, revealed in Superior Supplies, the primary to microfabricate three-dimensional (3D) overlapped microdenticles with sharp microriblets. The 3D synthetic sharkskin was in a position to obtain a number of functionalities by mimicking morphological and materials traits of the pure sharkskin.

Many earlier research have been performed to develop synthetic sharkskin that mimics pure sharkskin with practical benefits. Nonetheless, it has been troublesome to type 3D overlapping morphology whereas sustaining the form of microriblets on the microdenticles. Undesired thermal deformation continues to be a problem for the polymer-based microdenticles periodically organized with slender interspacing.

To resolve this drawback, Wie and his colleagues fabricated riblet-textured microdenticles utilizing a composite of magnetic particles and elastomeric polymers. Subsequent, 3D microdenticles have been induced to bend till they overlapped one another underneath an exterior magnetic area.

Whereas an fascinating idea, there’s a must shape-fix this magnetic overlapping to functionalize sharkskin underneath the removing of the magnetic area. “We newly developed a chemical shape-fixation technique to fabricate 3D staggered-overlapped sharkskin,” mentioned Jeong Jae Wie, a professor within the Division of Natural and Nano Engineering at Hanyang College.

“The microdenticles must be actuated in reverse path to coat a skinny layer of a liquid resin of polymer on the sharkskin. After altering actuation in a ahead path, a skinny polymer layer is cured, finishing microfabrication of 3D synthetic sharkskin with immobilized magnetic overlapping,” mentioned Jeong Eun Park, a primary writer within the revealed examine.

“A singular level of this work is the flexibility of their 3D synthetic sharkskin to reveal a number of functionalities whereas different research have solely been in a position to doc one or two options,” mentioned Wie’s collaborator, Seung Goo Lee of College of Ulsan.

The analysis group first confirmed drag discount, a consultant performance of pure sharkskin. 3D synthetic sharkskin with hydrophobicity reduces drag when water flows within the frontal path of the microriblets.

“In our hydrophobic sharkskin, micro-sized air bubbles are trapped amongst overlapped microdenticles, inflicting slip of water layer on the air bubbles,” added Wie’s collaborator, Rhokyun Kwak of Hanyang College.

Along with this drag discount performance, their 3D synthetic sharkskin reveals low friction when scratching pattern within the frontal path and excessive mechanical robustness with structural restoration, owing to the structure of staggered-overlapped microdenticles.

“Curiously, these functionalities could possibly be improved by coating the mechanically gentle polymer-based sharkskin with nanoscale skinny layer of mechanically brittle materials. This idea is motivated by the hard-on-soft layered construction of the pure sharkskin,” added Wie.

“Usually, mechanically gentle movie has excessive floor friction towards contact with surrounding obstacles. Nonetheless, on this work, the coefficient of friction decreases when coating sharkskin with a skinny ceramic as a result of onerous and versatile traits coexist on this tri-layered sharkskin,” defined Wie’s collaborator, Sanha Kim of Korea Superior Institute of Science and Know-how.

Subsequently, Wie’s group coated the tri-layered sharkskin with a skinny steel. In a take a look at of indentation, quad-layered sharkskin exhibited enhanced hardness and recoverable work, when in comparison with the noncoated polymeric sharkskin. Particularly within the characteristic of structural restoration, “Recoverable work may be saved within the bent microdenticles whereas the skinny layers of mechanically brittle supplies might improve the elastic pressure vitality of the 3D synthetic sharkskin,” added Kim.

Moreover, for microtextured digital functions, when the polymer-based sharkskin is coated with an electrically conductive MXene materials, it has a low electrical resistance of 5.3 Ω.

“MXene-coated sharkskin permits joule heating with excessive temperature even when a low voltage is utilized (e.g., 230°C at 2.75 V). As well as, due to the hydrophilicity of MXene materials, wetting properties of sharkskin additionally modifications from hydrophobic to hydrophilic,” mentioned Wie’s collaborator, Tae Hee Han of Hanyang College.

“This analysis is the primary to report on a number of functionalities demonstrable by the 3D synthetic sharkskin, with many potential functions in a wide range of fields,” mentioned Lee. For instance, if the know-how of this multifunctional synthetic sharkskin was to be utilized within the transport trade, financial effectivity could possibly be generated by decreasing gas consumption and rising the service lifetime of the ship.

“As for future functions, ships with our 3D synthetic sharkskin may be anticipated to quick navigate with decreased drag, much less friction in touch with surrounding obstacles, and fewer injury from exterior impacts within the ocean,” added Wie.

Extra info:

Jeong Eun Park et al, Programming Anisotropic Performance of 3D Microdenticles by Staggered‐Overlapped and Multilayered Microarchitectures, Superior Supplies (2023). DOI: 10.1002/adma.202309518

Offered by

Hanyang College

Quotation:

A brand new microfabrication technique for multifunctional 3D synthetic sharkskin (2023, December 12)

retrieved 13 December 2023

from https://phys.org/information/2023-12-microfabrication-strategy-multifunctional-3d-artificial.html

This doc is topic to copyright. Other than any truthful dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is offered for info functions solely.