When water vapor meets steel, the ensuing corrosion can result in mechanical issues that hurt a machine’s efficiency. By a course of known as passivation, it can also type a skinny inert layer that acts as a barrier in opposition to additional deterioration.

Both method, the precise chemical response isn’t effectively understood on an atomic stage, however that’s altering due to a way known as environmental transmission electron microscopy (TEM), which permits researchers to immediately view molecules interacting on the tiniest potential scale.

Professor Guangwen Zhou—a school member at Binghamton College’s Thomas J. Watson Faculty of Engineering and Utilized Science—has been probing the secrets and techniques of atomic reactions since becoming a member of the Division of Mechanical Engineering in 2007. Together with collaborators from the College of Pittsburgh and the Brookhaven Nationwide Laboratory, he has studied the structural and practical properties of metals and the method of creating “inexperienced” metal.

Their newest analysis, “Atomistic mechanisms of water vapor induced floor passivation,” was printed in November within the journal Science Advances.

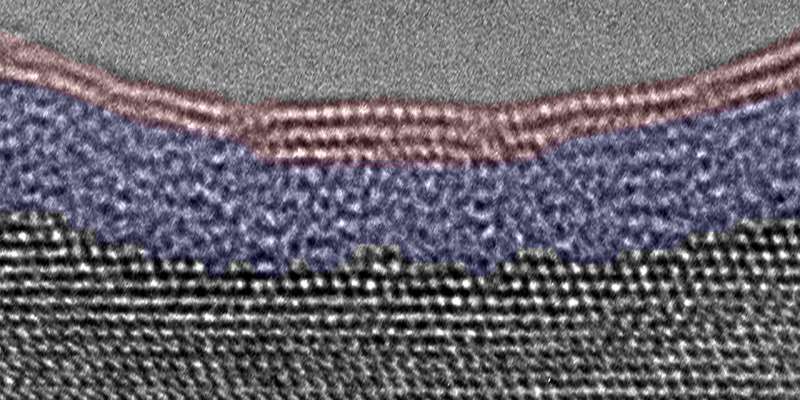

Within the paper, Zhou and his crew launched water vapor to scrub aluminum samples and noticed the floor reactions.

“This phenomenon is well-known as a result of it occurs in our day by day lives,” he mentioned. “However how do water molecules react with aluminum to type this passivation layer? When you take a look at the [research] literature, there’s not a lot work about how this occurs at an atomic scale. If we wish to use it for good, we should know as a result of then we could have some approach to management it.”

They found one thing that had by no means been noticed earlier than: Along with the aluminum hydroxide layer that shaped on the floor, a second amorphous layer developed beneath it, which signifies there’s a transport mechanism that diffuses oxygen into the substrate.

“Most corrosion research concentrate on the expansion of the passivation layer and the way it slows down the corrosion course of,” Zhou mentioned. “To have a look at it from an atomic scale, we really feel we will bridge the data hole.”

The price of repairing corrosion worldwide is estimated at $2.5 trillion a yr, which is greater than 3% of the worldwide GDP—so growing higher methods to handle oxidation can be an financial boon.

Moreover, understanding how a water molecule’s hydrogen and oxygen atoms break aside to work together with metals may result in clean-energy options, which is why the U.S. Division of Vitality funded this analysis and Zhou’s comparable initiatives up to now.

“When you break water into oxygen and hydrogen while you recombine it, it is simply water once more,” he mentioned. “It would not have the contamination of fossil fuels, and it would not produce carbon dioxide.”

Due to the clean-energy implications, the DOE has usually renewed Zhou’s grant funding over the previous 15 years.

“I drastically admire the long-term assist for this analysis,” Zhou mentioned. “It is an important difficulty for power gadgets or power methods as a result of you have got numerous metallic alloys which are used as structural materials.”

Extra data:

Xiaobo Chen et al, Atomistic mechanisms of water vapor–induced floor passivation, Science Advances (2023). DOI: 10.1126/sciadv.adh5565

Supplied by

Binghamton College

Quotation:

New analysis examines corrosion on atomic stage (2023, December 11)

retrieved 11 December 2023

from https://phys.org/information/2023-12-corrosion-atomic.html

This doc is topic to copyright. Other than any honest dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for data functions solely.