A plump piece of farm-fresh rooster leg rested on a pristine floor at Harvard Medical Faculty. Pores and skin on and bone in, it was exactly sliced to barely crack the bone.

A robotic arm swerved over, scanned the breakage, and thoroughly injected a liquid cocktail of substances into the crack, together with some remoted from seaweed. With a number of pulses of ultrasound, the liquid hardened right into a bone-like materials and sealed the fracture.

This wasn’t an avant-garde dinner present. Slightly, it was an modern experiment to see if ultrasound can sooner or later be used to 3D print implants instantly inside our physique.

Led by Dr. Yu Shrike Zhang at Brigham and Ladies’s Hospital and Harvard Medical Faculty, a latest research mixed the distinctive properties of ultrasound and 3D printing to restore broken tissue. On the coronary heart of the know-how is a combination of chemical substances that gel in response to sonic waves—a concoction dubbed “sono-ink.”

In a single take a look at, the staff 3D printed a cartoonish bone form inside a hefty piece of remoted pork stomach, the ultrasound simply penetrating layers of fatty pores and skin and tissue. The know-how additionally made beehive-like buildings inside remoted pork livers and a coronary heart form in kidneys.

It might sound macabre, however the aim isn’t to 3D print emojis inside dwelling tissue. Slightly, medical doctors might sooner or later use ultrasound and sono-ink to instantly restore broken organs contained in the physique as a substitute for invasive surgical procedure.

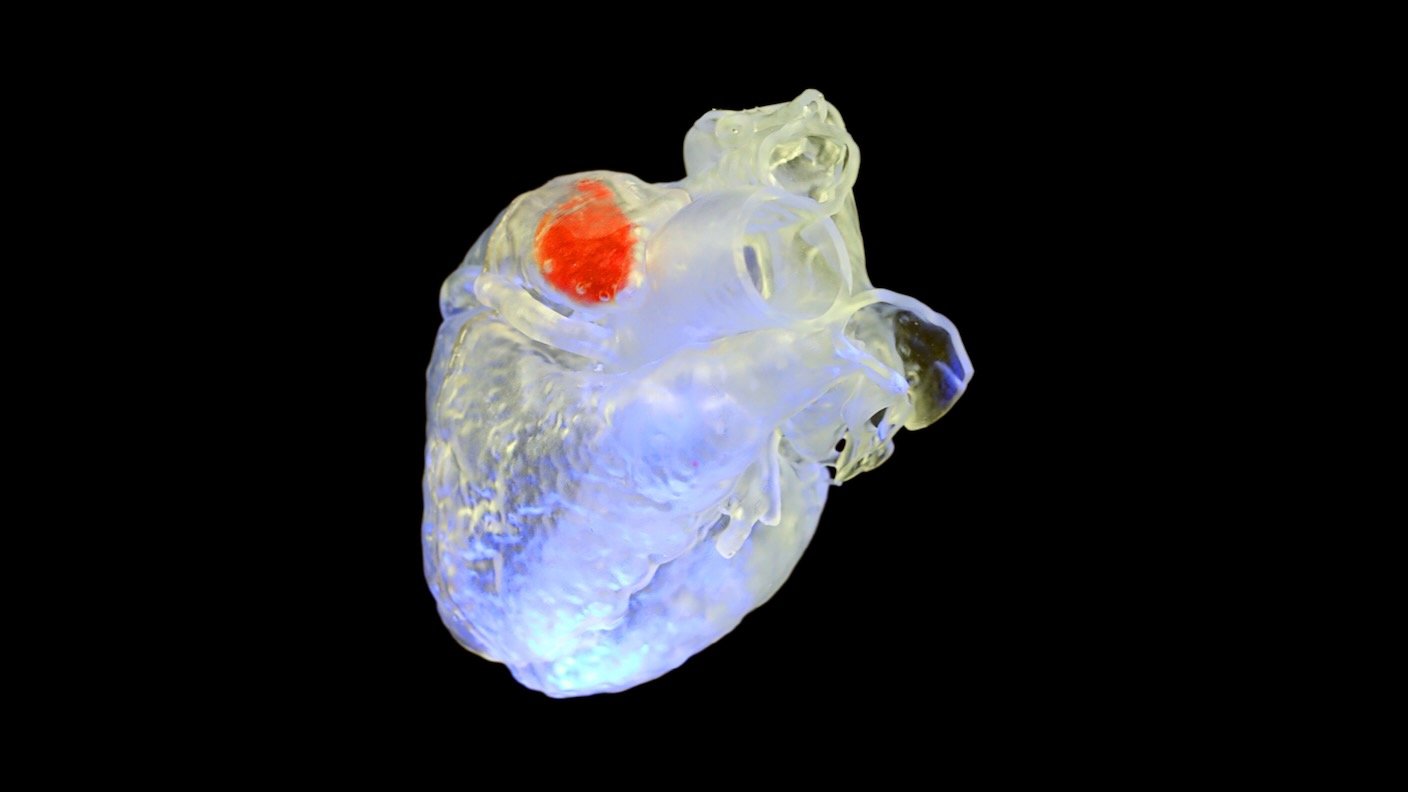

As a proof of idea, the staff used sono-ink to restore a damaged area of an remoted goat coronary heart. After a number of blasts of ultrasound, the ensuing patch gelled and meshed seamlessly with surrounding coronary heart tissue, basically turning into a biocompatible, stretchable bandage.

One other take a look at loaded the sono-ink with a chemotherapy drug and injected the concoction right into a broken liver. Inside minutes, the ink launched the drug into injured areas, whereas sparing a lot of the wholesome surrounding cells.

The know-how affords a approach of changing open surgical procedures into less-invasive remedies, wrote Drs. Yuxing Yao and Mikhail Shapiro on the California Institute of Expertise, who weren’t concerned within the research. It may be used to print body-machine interfaces that reply to ultrasound, make versatile electronics for coronary heart accidents, or effectively ship anti-cancer medication straight to the supply after surgical procedure to restrict uncomfortable side effects.

“We’re nonetheless removed from bringing this software into the clinic, however these checks reaffirmed the potential of this know-how,” stated Zhang. “We’re very excited to see the place it will possibly go from right here.”

From Mild to Sound

Due to its versatility, 3D printing has captured bioengineers’ creativeness on the subject of constructing synthetic organic elements—for instance, stents for life-threatening coronary heart illness.

The method is often iterative. An inkjet 3D printer—just like an workplace printer—sprays out a skinny layer and “cures” it with gentle. This solidifies the liquid ink after which, layer by layer, the printer builds a whole construction. But gentle can solely illuminate the floor of many supplies, making it unimaginable to generate a totally printed 3D construction with one blast.

The brand new research turned to volumetric printing, the place a printer tasks gentle right into a quantity of liquid resin, solidifying the resin into the article’s construction—and voilà, the article is constructed complete.

The method is far sooner and produces objects with smoother surfaces than conventional 3D printing. But it surely’s restricted by how far gentle can shine by means of the ink and surrounding materials—for instance, pores and skin, muscle, and different tissues.

Right here’s the place ultrasound is available in. Finest recognized for maternal care, low ranges of ultrasound simply penetrate opaque layers—akin to pores and skin or muscle—with out hurt. Known as centered ultrasound, researchers are exploring the know-how to watch and stimulate the mind and different tissues.

It has drawbacks. Sound waves blur when touring by means of liquids, that are considerable in our our bodies. Used to 3D print buildings, the sound waves might generate an abomination of the unique design. To construct an acoustic 3D printer, step one was to revamp the ink.

A Sound Recipe

The staff first experimented with ink designs that treatment with ultrasound. The recipe they got here up with is a soup of molecules. Some solidify when heated; others soak up sound waves.

The sono-ink transforms right into a gel in simply minutes after ultrasound pulses.

The method is self-propelling, defined Yao and Shapiro. Ultrasound triggers a chemical response that generates warmth which is absorbed into the gel and accelerates the cycle. As a result of the ultrasound supply is managed by a robotic arm, it’s attainable to focus the sound waves to a decision of 1 millimeter—a bit thicker than your common bank card.

The staff examined a number of sono-ink recipes and 3D printed easy buildings, like a multi-colored three-piece gear and glow-in-the-dark buildings resembling blood vessels. This helped the staff probe the bounds of the system and discover potential makes use of: A fluorescent 3D-printed implant, for instance, might be simpler to trace contained in the physique.

Sound Success

The staff subsequent turned to remoted organs.

In a single take a look at, they injected sono-ink right into a broken goat coronary heart. An identical situation in people can result in lethal blood clots and coronary heart assaults. The widespread therapy is open-heart surgical procedure.

Right here, the staff infused sono-ink instantly into the goat coronary heart by means of blood vessels. With exactly centered ultrasound pulses the ink gelled to guard the broken area—with out harming neighboring elements—and linked with the center’s personal tissues.

In one other take a look at, they injected the ink right into a rooster leg bone fracture and reconstructed the bone “with seamless bonding to the native elements,” the authors wrote.

In a 3rd take a look at, they combined doxorubicin, a chemotherapy drug typically utilized in breast most cancers, into the sono-ink and injected it into broken elements of a pork liver. With blasts of ultrasound, the ink settled into the broken areas and step by step launched the drug into the liver over the subsequent week. The staff thinks this technique might assist enhance most cancers therapy after the surgical removing of tumors, they defined.

The system is only a begin. Sono-ink hasn’t but been examined inside a dwelling physique, and it might set off poisonous results. And whereas ultrasound is mostly secure, the stimulation can improve sound-wave stress and warmth tissues as much as a really toasty 158 levels Fahrenheit. To Yao and Shapiro, these challenges can information the know-how.

The power to shortly print gentle 3D supplies opens the door to new body-machine interfaces. Organ patches with embedded electronics might assist long-term take care of folks with continual coronary heart illness. Ultrasound might additionally spur tissue regeneration in deeper elements of the physique with out invasive surgical procedure.

Biomedical functions apart, sono-ink might even make a splash in our on a regular basis world. 3D-printed footwear, for instance, have made a splash. It’s attainable “the trainers of the longer term might be printed with the identical acoustic technique that repairs bones,” wrote Yao and Shapiro.

Picture Credit score: Alex Sanchez, Duke College; Junjie Yao, Duke College; Y. Shrike Zhang, Harvard Medical Faculty