Dec 11, 2023

(

Nanowerk Information) MIT researchers have used 3D printing to provide self-heating microfluidic units, demonstrating a way which might sometime be used to quickly create low cost, but correct, instruments to detect a bunch of illnesses.

Key Takeaways

This innovation makes use of multimaterial extrusion 3D printing, combining a biodegradable polymer with copper-doped PLA to create units that may exactly warmth fluids.

The approach allows the manufacturing of advanced microfluidic units in a single step, considerably decreasing the associated fee and time concerned in manufacturing.

These self-heating microfluidics are significantly helpful for distant or creating areas, the place entry to costly lab gear is proscribed.

Future enhancements could embody integrating temperature sensing and utilizing supplies that may face up to increased temperatures for a wider vary of functions.

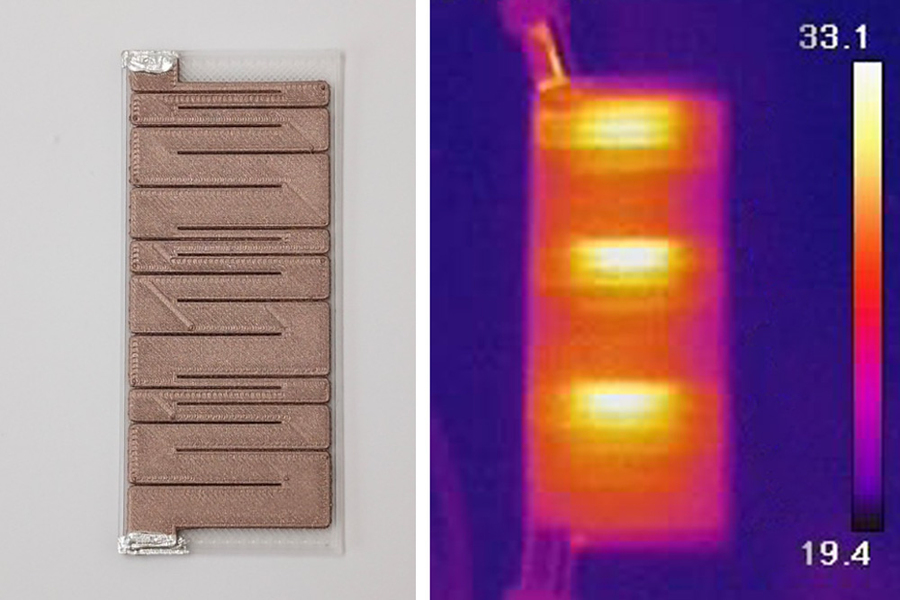

The self-heating microfluidic units, such because the one proven, may be made quickly and cheaply in giant numbers, and will sometime assist clinicians in distant components of the world detect illnesses with out the necessity for costly lab gear. (Picture: Courtesy of the researchers)

The Analysis

Microfluidics, miniaturized machines that manipulate fluids and facilitate chemical reactions, can be utilized to detect illness in tiny samples of blood or fluids. At-home take a look at kits for Covid-19, for instance, incorporate a easy kind of microfluidic.

However many microfluidic functions require chemical reactions that should be carried out at particular temperatures. These extra advanced microfluidic units, that are sometimes manufactured in a clear room, are outfitted with heating components created from gold or platinum utilizing a sophisticated and costly fabrication course of that’s troublesome to scale up.

As a substitute, the MIT workforce used multimaterial 3D printing to create self-heating microfluidic units with built-in heating components, by way of a single, cheap manufacturing course of. They generated units that may warmth fluid to a particular temperature because it flows by way of microscopic channels contained in the tiny machine.

Their approach is customizable, so an engineer might create a microfluidic that heats fluid to a sure temperature or given heating profile inside a particular space of the machine. The low-cost fabrication course of requires about $2 of supplies to generate a ready-to-use microfluidic.

The method might be particularly helpful in creating self-heating microfluidics for distant areas of creating international locations the place clinicians could not have entry to the costly lab gear required for a lot of diagnostic procedures.

“Clear rooms specifically, the place you’d often make these units, are extremely costly to construct and to run. However we are able to make very succesful self-heating microfluidic units utilizing additive manufacturing, and they are often made so much quicker and cheaper than with these conventional strategies. That is actually a option to democratize this know-how,” says Luis Fernando Velásquez-García, a principal scientist in MIT’s Microsystems Know-how Laboratories (MTL) and senior writer of a paper describing the fabrication approach.

He’s joined on the paper by lead writer Jorge Cañada Pérez-Sala, {an electrical} engineering and pc science graduate scholar. The analysis will probably be offered on the PowerMEMS Convention this month.

An insulator turns into conductive

This new fabrication course of makes use of a way referred to as multimaterial extrusion 3D printing, during which a number of supplies may be squirted by way of the printer’s many nozzles to construct a tool layer by layer. The method is monolithic, which implies the complete machine may be produced in a single step on the 3D printer, with out the necessity for any post-assembly.

To create self-heating microfluidics, the researchers used two supplies — a biodegradable polymer often known as polylactic acid (PLA) that’s generally utilized in 3D printing, and a modified model of PLA.

The modified PLA has blended copper nanoparticles into the polymer, which converts this insulating materials into {an electrical} conductor, Velásquez-García explains. When electrical present is fed right into a resistor composed of this copper-doped PLA, vitality is dissipated as warmth.

“It’s wonderful when you concentrate on it as a result of the PLA materials is a dielectric, however whenever you put in these nanoparticle impurities, it utterly modifications the bodily properties. That is one thing we don’t totally perceive but, however it occurs and it’s repeatable,” he says.

Utilizing a multimaterial 3D printer, the researchers fabricate a heating resistor from the copper-doped PLA after which print the microfluidic machine, with microscopic channels by way of which fluid can movement, instantly on prime in a single printing step. As a result of the elements are created from the identical base materials, they’ve comparable printing temperatures and are suitable.

Warmth dissipated from the resistor will heat fluid flowing by way of the channels within the microfluidic.

Along with the resistor and microfluidic, they use the printer so as to add a skinny, steady layer of PLA that’s sandwiched between them. It’s particularly difficult to fabricate this layer as a result of it should be skinny sufficient so warmth can switch from the resistor to the microfluidic, however not so skinny that fluid might leak into the resistor.

The ensuing machine is in regards to the dimension of a U.S. quarter and may be produced in a matter of minutes. Channels about 500 micrometers large and 400 micrometers tall are threaded by way of the microfluidic to hold fluid and facilitate chemical reactions.

Importantly, the PLA materials is translucent, so fluid within the machine stays seen. Many processes depend on visualization or using gentle to deduce what is occurring throughout chemical reactions, Velásquez-García explains.

Customizable chemical reactors

The researchers used this one-step manufacturing course of to generate a prototype that would warmth fluid by 4 levels Celsius because it flowed between the enter and the output. This customizable approach might allow them to make units which might warmth fluids in sure patterns or alongside particular gradients.

“You need to use these two supplies to create chemical reactors that do precisely what you need. We will arrange a specific heating profile whereas nonetheless having all of the capabilities of the microfluidic,” he says.

Nonetheless, one limitation comes from the truth that PLA can solely be heated to about 50 levels Celsius earlier than it begins to degrade. Many chemical reactions, equivalent to these used for polymerase chain response (PCR) exams, require temperatures of 90 levels or increased. And to exactly management the temperature of the machine, researchers would want to combine a 3rd materials that permits temperature sensing.

Along with tackling these limitations in future work, Velásquez-García needs to print magnets instantly into the microfluidic machine. These magnets might allow chemical reactions that require particles to be sorted or aligned.

On the identical time, he and his colleagues are exploring using different supplies that would attain increased temperatures. They’re additionally learning PLA to raised perceive why it turns into conductive when sure impurities are added to the polymer.

“If we are able to perceive the mechanism that’s associated to {the electrical} conductivity of PLA, that will significantly improve the aptitude of those units, however it’s going to be so much tougher to resolve than another engineering issues,” he provides.

“In Japanese tradition, it’s typically mentioned that magnificence lies in simplicity. This sentiment is echoed by the work of Cañada and Velasquez-Garcia. Their proposed monolithically 3D-printed microfluidic techniques embody simplicity and sweetness, providing a big selection of potential derivations and functions that we foresee sooner or later,” says Norihisa Miki, a professor of mechanical engineering at Keio College in Tokyo, who was not concerned with this work.

“Having the ability to instantly print microfluidic chips with fluidic channels and electrical options on the identical time opens up very exiting functions when processing organic samples, equivalent to to amplify biomarkers or to actuate and blend liquids. Additionally, attributable to the truth that PLA degrades over time, one may even consider implantable functions the place the chips dissolve and resorb over time,” provides Niclas Roxhed, an affiliate professor at Sweden’s KTH Royal Institute of Know-how, who was not concerned with this research.

The self-heating microfluidic units, such because the one proven, may be made quickly and cheaply in giant numbers, and will sometime assist clinicians in distant components of the world detect illnesses with out the necessity for costly lab gear. (Picture: Courtesy of the researchers)

The self-heating microfluidic units, such because the one proven, may be made quickly and cheaply in giant numbers, and will sometime assist clinicians in distant components of the world detect illnesses with out the necessity for costly lab gear. (Picture: Courtesy of the researchers)

The self-heating microfluidic units, such because the one proven, may be made quickly and cheaply in giant numbers, and will sometime assist clinicians in distant components of the world detect illnesses with out the necessity for costly lab gear. (Picture: Courtesy of the researchers)

The self-heating microfluidic units, such because the one proven, may be made quickly and cheaply in giant numbers, and will sometime assist clinicians in distant components of the world detect illnesses with out the necessity for costly lab gear. (Picture: Courtesy of the researchers)