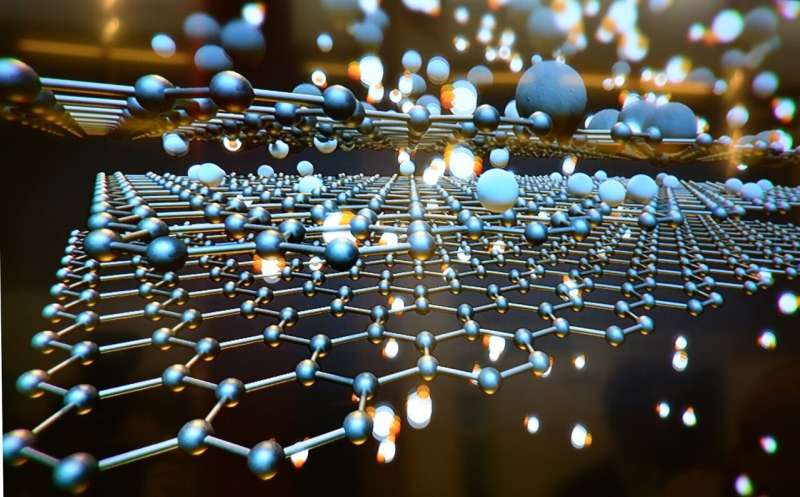

Two-dimensional supplies, that are only some atoms thick, can exhibit some unbelievable properties, akin to the power to hold electrical cost extraordinarily effectively, which may increase the efficiency of next-generation digital gadgets.

Nevertheless, integrating 2D supplies into gadgets and methods like laptop chips is notoriously tough. These ultrathin buildings could be broken by typical fabrication methods, which regularly depend on the usage of chemical compounds, excessive temperatures, or harmful processes like etching.

To beat this problem, researchers from MIT and elsewhere have developed a brand new approach to combine 2D supplies into gadgets in a single step whereas conserving the surfaces of the supplies and the ensuing interfaces pristine and free from defects.

Their methodology depends on engineering floor forces accessible on the nanoscale to permit the 2D materials to be bodily stacked onto different prebuilt system layers. As a result of the 2D materials stays undamaged, the researchers can take full benefit of its distinctive optical and electrical properties.

They used this strategy to manufacture arrays of 2D transistors that achieved new functionalities in comparison with gadgets produced utilizing typical fabrication methods. Their methodology, which is flexible sufficient for use with many supplies, may have various purposes in high-performance computing, sensing, and versatile electronics.

Core to unlocking these new functionalities is the power to kind clear interfaces, held collectively by particular forces that exist between all matter, known as van der Waals forces.

Nevertheless, such van der Waals integration of supplies into totally useful gadgets isn’t all the time simple, says Farnaz Niroui, assistant professor {of electrical} engineering and laptop science (EECS), a member of the Analysis Laboratory of Electronics (RLE), and senior creator of a brand new paper describing the work.

“Van der Waals integration has a basic restrict,” she explains. “Since these forces rely upon the intrinsic properties of the supplies, they can’t be readily tuned. Because of this, there are some supplies that can’t be instantly built-in with one another utilizing their van der Waals interactions alone. We’ve developed a platform to deal with this restrict to assist make van der Waals integration extra versatile, to advertise the event of 2D-materials-based gadgets with new and improved functionalities.”

The analysis will likely be printed in Nature Electronics.

Advantageous attraction

Making advanced methods akin to a pc chip with typical fabrication methods can get messy. Usually, a inflexible materials like silicon is chiseled all the way down to the nanoscale after which interfaced with different parts like steel electrodes and insulating layers to kind an lively system. Such processing could cause harm to the supplies.

Not too long ago, researchers have centered on constructing gadgets and methods from the underside up, utilizing 2D supplies and a course of that requires sequential bodily stacking. On this strategy, slightly than utilizing chemical glues or excessive temperatures to bond a fragile 2D materials to a traditional floor like silicon, researchers leverage van der Waals forces to bodily combine a layer of 2D materials onto a tool.

Van der Waals forces are pure forces of attraction that exist between all matter. For instance, a gecko’s ft can keep on with the wall briefly on account of van der Waals forces.

Although all supplies exhibit a van der Waals interplay, relying on the fabric, the forces are usually not all the time robust sufficient to carry them collectively. As an illustration, a well-liked semiconducting 2D materials referred to as molybdenum disulfide will keep on with gold, a steel, however will not instantly switch to insulators like silicon dioxide by simply coming into bodily contact with that floor.

Nevertheless, heterostructures made by integrating semiconductor and insulating layers are key constructing blocks of an digital system. Beforehand, this integration has been enabled by bonding the 2D materials to an intermediate layer like gold, then utilizing this intermediate layer to switch the 2D materials onto the insulator earlier than eradicating the intermediate layer utilizing chemical compounds or excessive temperatures.

As an alternative of utilizing this sacrificial layer, the MIT researchers embed the low-adhesion insulator in a high-adhesion matrix. This adhesive matrix is what makes the 2D materials keep on with the embedded low-adhesion floor, offering the forces wanted to create a van der Waals interface between the 2D materials and the insulator.

Making the matrix

To make digital gadgets, they kind a hybrid floor of metals and insulators on a service substrate. This floor is then peeled off and flipped over to disclose a very easy prime floor that comprises the constructing blocks of the specified system.

This smoothness is necessary since gaps between the floor and 2D materials can hamper van der Waals interactions. Then, the researchers put together the 2D materials individually in a very clear atmosphere and produce it into direct contact with the ready system stack.

“As soon as the hybrid floor is introduced into contact with the 2D layer, with no need any excessive temperatures, solvents, or sacrificial layers, it will probably choose up the 2D layer and combine it with the floor. This manner, we’re permitting a van der Waals integration that might be historically forbidden however now could be doable and permits the formation of totally functioning gadgets in a single step,” Satterthwaite explains.

This single-step course of retains the 2D materials interface utterly clear, which permits the fabric to succeed in its basic limits of efficiency with out being held again by defects or contamination.

And since the surfaces additionally stay pristine, researchers can engineer the floor of the 2D materials to kind options or connections to different parts. For instance, they used this method to create p-type transistors, that are typically difficult to make with 2D supplies. Their transistors have improved on earlier research and might present a platform for finding out and reaching the efficiency wanted for sensible electronics.

Their strategy could be achieved at scale to make bigger arrays of gadgets. The adhesive matrix approach can be used with a spread of supplies and even with different forces to boost the flexibility of this platform. As an illustration, the researchers built-in graphene onto a tool, forming the specified van der Waals interfaces utilizing a matrix made with a polymer. On this case, adhesion depends on chemical interactions slightly than van der Waals forces alone.

Sooner or later, the researchers wish to construct on this platform to allow integration of a various library of 2D supplies to review their intrinsic properties with out the affect of processing harm and develop new system platforms that leverage these superior functionalities.

Extra info:

Farnaz Niroui et al, Van der Waals integration past the bounds of van der Waals forces utilizing adhesive matrix switch, Nature Electronics (2023). DOI: 10.1038/s41928-023-01079-8

Supplied by

Massachusetts Institute of Expertise

This story is republished courtesy of MIT Information (net.mit.edu/newsoffice/), a well-liked website that covers information about MIT analysis, innovation and educating.

Quotation:

Researchers safely combine fragile 2D supplies into gadgets, opening a path to distinctive digital properties (2023, December 8)

retrieved 10 December 2023

from https://phys.org/information/2023-12-safely-fragile-2nd-materials-devices.html

This doc is topic to copyright. Other than any truthful dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for info functions solely.