Ammonia (NH3) is considered a promising carbon-free vitality service, however its energy-intensive manufacturing course of nonetheless challenges international scientists. A analysis staff led by Metropolis College of Hong Kong (CityU) lately engineered a bimetallic alloy as an ultrathin nanocatalyst that may ship tremendously improved electrochemical efficiency for producing ammonia from nitrate (NO3–), providing nice potential for acquiring carbon-neutral gas sooner or later.

The findings have been revealed within the journal the Proceedings of the Nationwide Academy of Sciences (PNAS) underneath the title “Atomic coordination setting engineering of bimetallic alloy nanostructures for environment friendly ammonia electrosynthesis from nitrate.”

Ammonia, which is usually utilized in fertilizer, has lately attracted quite a lot of consideration as a result of it may possibly present a supply of hydrogen for gas cells, and it’s simpler to liquefy and transport than hydrogen. Owing to its enormous demand, upcycling nitrate (NO3–) from ammonium fertilizer-polluted wastewater has emerged as a substitute for reproducing priceless ammonia and making agriculture extra sustainable.

Presently, electrochemical nitrate discount response (NO3RR) is considered a promising resolution for ammonia synthesis. It includes primarily deoxygenation and hydrogenation steps (i.e. NO3– + 9H+ + 8e– ➙ NH3 + 3H2O) with metal-based electrocatalysts.

“Nevertheless, the undesired by-products and the competing hydrogen evolution response (HER) throughout NO3RR apparently hinders the yield price of ammonia manufacturing,” stated Professor Fan Zhanxi, of the Division of Chemistry at CityU, who led the research.

As an alternative of modulating the electrocatalysts’ dimension or dimension, as different earlier analysis did, Professor Fan’s staff targeted on enhancing the energetic websites, the place substrate molecules bind and catalysis takes place on the floor of the electrocatalysts.

“Ruthenium (Ru) is an rising materials as an electrocatalyst for NO3RR, nevertheless it additionally has the issue of favoring HER, which results in its energetic websites being extremely occupied by undesired energetic hydrogen, leaving inadequate space for nitrate discount into ammonia,” defined Professor Fan.

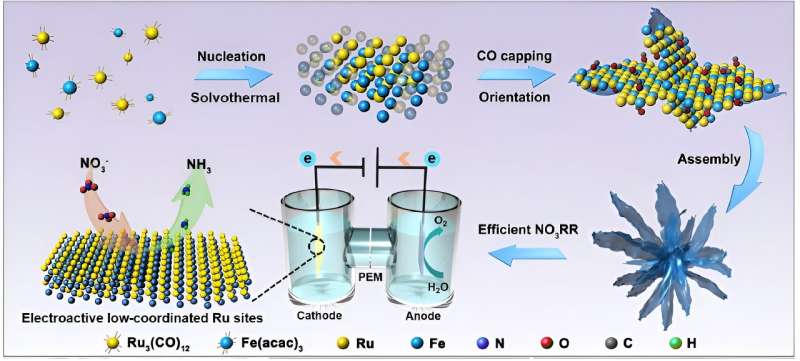

To beat the challenges, the staff launched one other steel—iron (Fe)—to modulate the atomic coordination setting of the energetic websites. By altering the coordination setting of the Ru websites, the digital constructions and floor properties of Ru and therefore their catalytic exercise for producing ammonia are optimized. To additional improve the electrocatalyst efficiency, the staff developed a one-pot synthesis method for making ultrathin nanosheets which are assembled as a flowerlike construction—known as RuFe nanoflowers.

This novel bimetallic alloy made-electrocatalyst possesses a extremely steady digital construction as a result of complementary orbitals that attain environment friendly electron switch and strong valence states, which additionally suppresses the aggressive HER and lowers the vitality boundaries for NO3RR. Furthermore, the electrochemically energetic floor websites of the RuFe nanoflowers measured 267.5 cm2, a lot bigger than the 105 cm2 for Ru-nanosheets for the reactions to happen.

Remarkably, RuFe nanoflowers demonstrated significantly better electrochemical efficiency, with an excellent cost switch effectivity, referred to as faradaic effectivity (FE), of 92.9% and a yield price of 38.68 mg h−1 mgcat−1 at −0.30 and −0.65 V for ammonia manufacturing, which is sort of 6.9 occasions that of sole Ru-nanosheets.

“This analysis signifies nice potential for RuFe nanoflowers in next-generation electrochemical vitality methods,” stated Professor Fan. “We imagine this work can stimulate follow-up research on modulating the atomic coordination setting of energetic websites in metal-based catalysts for ammonia manufacturing, additional selling a sustainable nitrogen cycle to realize carbon-free vitality sooner or later.”

Extra data:

Yunhao Wang et al, Atomic coordination setting engineering of bimetallic alloy nanostructures for environment friendly ammonia electrosynthesis from nitrate, Proceedings of the Nationwide Academy of Sciences (2023). DOI: 10.1073/pnas.2306461120

Supplied by

Metropolis College of Hong Kong

Quotation:

Bimetallic alloy nanocatalyst boosts environment friendly ammonia manufacturing with potential for carbon-free vitality (2023, December 8)

retrieved 9 December 2023

from https://phys.org/information/2023-12-bimetallic-alloy-nanocatalyst-boosts-efficient.html

This doc is topic to copyright. Aside from any honest dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for data functions solely.