Information briefs for the week check out a live-in robotic misplaced & discovered for dementia victims, Mitsubishi lastly goes in massive for AMRs, KUKU and Heller co-develop cellular robotic for CNC device deliveries, spot welding comes of age on the tip of a UR cobot, mushy robotic in a minimally invasive function for epileptic seizures and different neurological issues.

Robotic Misplaced & Discovered

Everybody loses issues at a while or one other. Most occasions we keep in mind sufficient to finally discover them. These with dementia however have a harder or near-impossible likelihood of restoration.

How a few robotic that is a wonderful misplaced & discovered agent?

How a few robotic that is a wonderful misplaced & discovered agent?

In 2020, estimates of almost 7 million folks ages 65 or older with various levels of dementia within the U.S., may nicely imply plenty of lacking eyeglasses, drugs bottles, cellphones, wallets, and the handfuls of different each day requirements which can be small and simply misplaced. Plus, persistent lack of private issues can diminish the standard of life and place burdens on caregivers to recuperate misplaced objects.

Dr. Ali Ayub and three companions in electrical and laptop engineering at Canada’s College of Waterloo (Waterloo, Ontario) had been struck by the quickly rising variety of folks dealing with dementia—9 million People may have dementia by 2030 and almost 12 million by 2040. The three got down to develop a robotic helper with abilities in misplaced & discovered. Unusually sufficient, it was the first-ever misplaced & discovered robotic. Nobody had beforehand ever tried to construct a robotic expert at discovering misplaced objects.

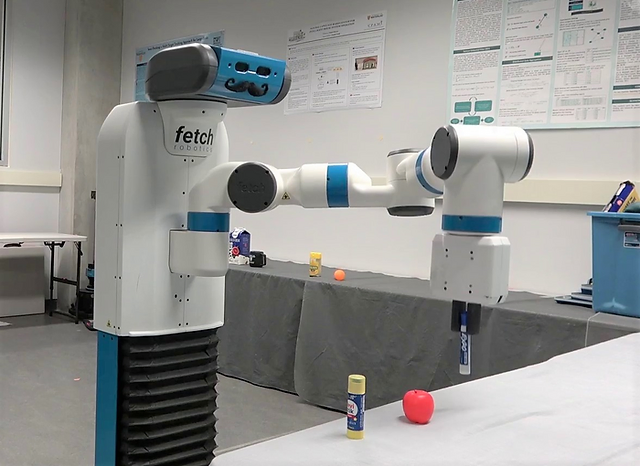

Utilizing a cellular robotic manipulator from Fetch Robotics, they created an object-detection algorithm to detect, observe and maintain a reminiscence log of particular objects within the robotic’s digicam view utilizing saved video.

With the robotic able to distinguishing one object from one other, it could actually file the time and date when an object enters or leaves its subject of view and thus can point out when and the place it final noticed the precise object.

Mitsubishi lastly goes cellular

Eventually each robotic vendor with out a line of cellular robots (AMRs) feels the strain to go “mobil” or threat getting left behind within the fast-moving international warehouse and manufacturing unit automation motion.

With a spate of acquisitions and mergers occurring round them within the cellular robotic trade, Mitsubishi Electrical has simply joined the membership with a transfer to rectify the lacking AMRs in its product line.

With a spate of acquisitions and mergers occurring round them within the cellular robotic trade, Mitsubishi Electrical has simply joined the membership with a transfer to rectify the lacking AMRs in its product line.

Canada’s Kitchener, Ontario-based Clearpath Robotics, guardian firm of OTTO Motors (OTTO launched in 2015) has entered into an settlement to produce Mitsubishi Electrical with its OTTO self-driving automobiles to move supplies round warehouses and manufacturing services.

As OTTO places it on its web site: “Sensible factories start with good AMRs and OTTO Autonomous Cellular Robots (AMRs) automate frequent materials dealing with duties, massive and small, to assist producers sort out labor shortages, scale their enterprise, and outperform the competitors.”

That is precisely what Mitsubishi says it wants, writing in a latest press launch: “Mitsubishi Electrical goals to strengthen its assist for full manufacturing unit optimization and automation by using AMR programs and proceed to contribute to the additional growth of producing automation.”

New robotic problem: “Enhanced Automation”

Low portions, excessive complexity – and as quick as doable appear to be the watchwords for many something manufactured lately. As such, producers are always looking out for any facet of manufacturing that may be additional automated or produced extra speedily.

To that time, robotic builder KUKA and CNC builder Heller have joined collectively to automate the beforehand handbook means of loading and unloading of machine instruments right into a CNC machine. In a mission mentioned to satisfy the “challenges of high quality, quantity, and velocity,” plus resolve the scarcity of expert staff, KUKA and Heller have developed what they name “enhancing automation” or the additional automation of an already automated activity or course of. Particularly, delivering a set of requested machine instruments to a CNC machine to carry out a selected job, and upon completion of the job, retrieving the instruments for supply to yet one more CNC machine in want.

To that time, robotic builder KUKA and CNC builder Heller have joined collectively to automate the beforehand handbook means of loading and unloading of machine instruments right into a CNC machine. In a mission mentioned to satisfy the “challenges of high quality, quantity, and velocity,” plus resolve the scarcity of expert staff, KUKA and Heller have developed what they name “enhancing automation” or the additional automation of an already automated activity or course of. Particularly, delivering a set of requested machine instruments to a CNC machine to carry out a selected job, and upon completion of the job, retrieving the instruments for supply to yet one more CNC machine in want.

As KUKA noticed it: “Whereas automation options are already nicely superior in such areas as palletizing, dealing with or meeting duties, device automation – the versatile and automatic loading and unloading of machines with instruments – remains to be in its infancy.”

There are tens of hundreds of CNC machines (laptop numerical management machines) on this planet which can be a part of a international market projected to succeed in $132.93 billion by 2030. KUKA and Heller could have simply created a very talked-about new enterprise with their new invention, which is actually a cellular robotic and articulated arm. The cellular device system can even spot broken instruments, after which discard and substitute them.

Common Robots debuts spot-welding cobot

Till now, the light-weight cobot was unable to execute spot welds due to the burden of the welding gun and the complexity of the welds. Previously, welding applied sciences corresponding to MIG welding have turn out to be fashionable decisions for cobots whereas spot welding remained prohibitive.

California-based Professional Spot Worldwide has provide you with an answer. The corporate claims that its i5s resistance spot welder to be used with a Common Robots cobot will ship as much as thrice extra manufacturing capability than handbook welding.

“We’ve married probably the most refined spot welder on this planet with probably the most refined cobot know-how to ship an answer for industrial spot welding that will increase productiveness, security, consistency and job reliability,” says Professional Spot Automation’s chief engineer, Bob Hamilton. “It’s the forefront of tomorrow, proper right here at present.”

“We’ve married probably the most refined spot welder on this planet with probably the most refined cobot know-how to ship an answer for industrial spot welding that will increase productiveness, security, consistency and job reliability,” says Professional Spot Automation’s chief engineer, Bob Hamilton. “It’s the forefront of tomorrow, proper right here at present.”

The worldwide spot-welding market in 2022 was $3 billion and rising at 3% CAGR. Nonetheless, when peripherals like hoses, tanks, and welding weapons, and many others., are included, the marketplace for 2026 is forecast as $11 billion.

In response to Professional Spot and Common Robots, these “subsequent technology” automated cobot spot welders can “sense materials thicknesses and resistance and alter its weld profiles robotically. It additionally captures knowledge about every weld that can be utilized for high quality management, traceability, and job repeatability.”

Wi-Fi connectivity of cobot spot welders permits for immediate updates, knowledge exports, and the flexibility to e-mail welding logs for efficiency reporting.

First exhibiting of this new-generation welder is at Automate 2023, Might 22-25, in Detroit.

Gentle robotic sensor below the skull

It could appear to be an alien creature, however if you happen to’re affected by epileptic seizures or different neurological issues, it’s a godsend. And that it’s positioned below the skull by way of a minimally invasive opening, makes all different mind displays look gargantuan as compared.

The idea, says Stéphanie Lacour on the Swiss Federal Institute of Know-how in Lausanne (Switzerland), is a brand new method for putting electrodes on the mind’s floor “in contrast with the normal technique, wherein surgeons reduce a big gap within the cranium the dimensions of the totally prolonged machine. There’s really a extremely massive floor space that you could attain with out doing a big craniotomy,” she provides.

The idea, says Stéphanie Lacour on the Swiss Federal Institute of Know-how in Lausanne (Switzerland), is a brand new method for putting electrodes on the mind’s floor “in contrast with the normal technique, wherein surgeons reduce a big gap within the cranium the dimensions of the totally prolonged machine. There’s really a extremely massive floor space that you could attain with out doing a big craniotomy,” she provides.

The mushy robotic, about 2 centimeters lengthy—and when totally prolonged covers a diameter of 4 centimeters (0.78 inch to 1.50 inches)—has six legs produced from a versatile silicone polymer. The legs resemble curved flower petals radiating round a central physique. Every leg accommodates electrodes for monitoring mind exercise.

“Future variations,” says Lacour, could possibly be bidirectional, not solely sensing mind exercise but additionally stimulating it. “Which may permit the machine to cease seizure exercise earlier than it begins, stimulate mind areas broken by stroke or act as a brain-machine interface to permit folks to regulate units.”