The local weather change dialogue has centered on GHG (greenhouse gases), and significantly CO2 (carbon dioxide). Development, apparently, is a significant supply of CO2 and varied strategies for minimizing and even eliminating the fuel have been proposed. Structural supplies like metal or cement come at a excessive value each in {dollars} and carbon dioxide emissions; constructing development and use accounts for an estimated 40% of emissions. On The Peggy Smedley Present on Tuesday, she’s going to characteristic Tapio Vehmas, CEO, Carbonaide, to deal with a how a pilot manufacturing line can produce carbon-negative concrete utilizing industrial aspect streams and carbon dioxide seize, utilization, and storage expertise. The final word purpose right here is to make manufacturing concrete carbon unfavourable.

Creating sustainable options to present supplies might assist mitigate local weather change and scale back carbon dioxide emissions. Steps are underway to impact change in how concrete and different supplies are processed whereas transportation strategies are being evaluated for his or her impression on the local weather.

One space for analysis has been wooden, particularly engineered wooden. Engineered wooden merchandise are a high-performance, constant, and environmentally optimistic alternative for development. Additionally referred to as composite wooden, man-made wooden, or manufactured board, engineered wooden features a vary of spinoff wooden merchandise that are manufactured by binding the strands, particles, fibers, or veneers of wooden, along with adhesives, to kind composite supplies.

These merchandise are engineered to specific design specs that are examined to fulfill nationwide or worldwide requirements. Engineered wooden merchandise are utilized in a wide range of development functions, from dwelling development to business buildings to merchandise used for joists and beams that substitute metal in lots of constructing initiatives.

The engineered wooden merchandise market is estimated to develop at a CAGR (compound annual progress fee) of 6.8% between 2022 and 2027, in accordance with Technavio. The dimensions of the market is forecast to extend by $6.35 billion. Rising residential and business development actions are notably driving the engineered wooden merchandise market progress.

Developed economies such because the U.S. are investing in infrastructure growth and the rising deal with actual property growth, in addition to the development of recent residences and workplaces, is predicted to extend the gross sales of recent wooden merchandise and furnishings. The rising demand for wooden merchandise can also be complemented by the rise in the variety of renovation and modification initiatives throughout key international locations such because the U.S., China, and India.

Nonetheless, the excessive volatility in uncooked materials costs could impede the engineered wooden merchandise market progress. The fluctuations in uncooked materials costs are estimated to have an antagonistic impact on profitability, the price of gross sales, and the flexibility of distributors to deal with the calls for of shoppers successfully. Fluctuating crude oil costs have a direct, antagonistic impact on the pricing methods of uncooked materials suppliers. Thus, the volatility in uncooked materials costs is estimated to be a key problem for the worldwide engineered wooden merchandise market in the course of the forecast interval.

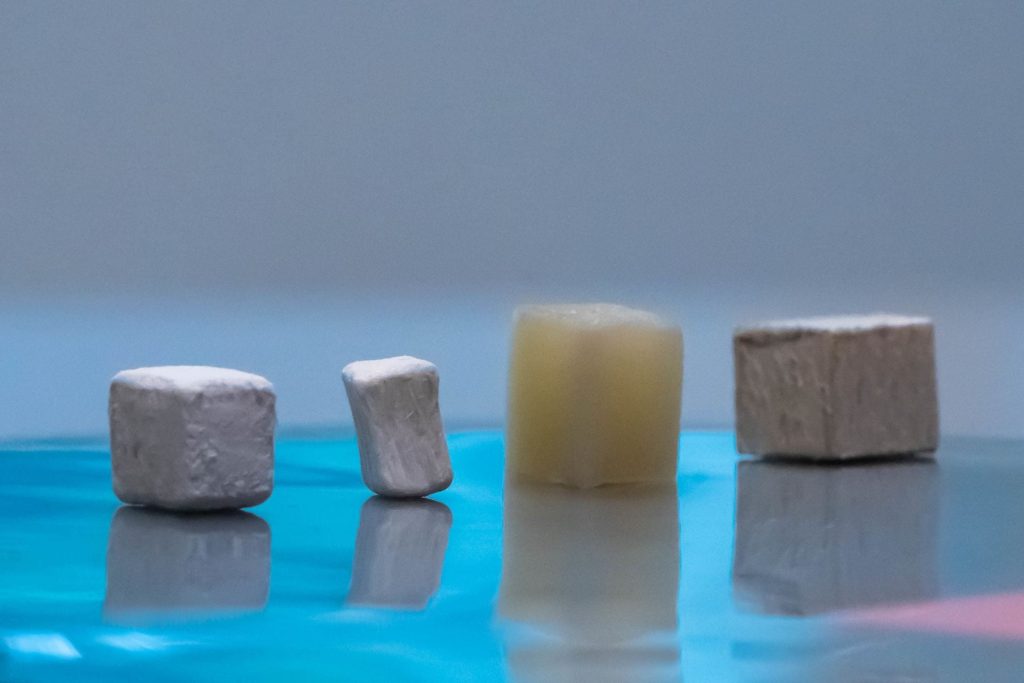

In the meantime, analysis is ongoing to seek out methods to enhance the engineered wooden presently being supplied by offering much more sustainable and resilient merchandise primarily based on structural wooden. For instance, Rice College scientists have discovered a strategy to engineer wooden to lure carbon dioxide via a doubtlessly scalable, energy-efficient course of that additionally makes the fabric stronger to be used in development. Working to deal with each points directly, supplies scientist Muhammad Rahman and collaborators discovered a method to include molecules of a carbon dioxide-trapping, porous crystalline materials into wooden.

Chemically, wooden is made up of three important elements: cellulose, hemicellulose, and lignin. Lignin is what provides wooden its colour, so once you take lignin out, the wooden turns into colorless. To attain the mandatory change, the community of cellulose fibers that offers wooden its energy is first cleared out via a course of often known as delignification.

Eradicating the lignin is a reasonably easy course of that entails a two-step chemical therapy utilizing environmentally benign substances. After eradicating the lignin, bleach or hydrogen peroxide is used to take away the hemicellulose.

Subsequent, the delignified wooden is soaked in an answer containing microparticles of a MOF (metal-organic framework, often known as Calgary framework 20 or (CALF-20), developed by College of Calgary Professor George Shimizu and others. MOFs are high-surface-area sorbent supplies used for his or her means to adsorb carbon dioxide molecules into their pores. The MOF particles simply match into the cellulose channels and get hooked up to them via favorable floor interactions.

MOFs are amongst a number of nascent carbon seize applied sciences developed to deal with anthropogenic local weather change. In response to Rice researchers, there isn’t a biodegradable, sustainable substrate for deploying carbon dioxide-sorbent supplies. Nonetheless, MOF-enhanced wooden is an adaptable help platform for deploying sorbent in several carbon dioxide functions.

Even so, most of the present MOFs usually are not very steady in various environmental situations. Some are very prone to moisture, and also you don’t need that in a structural materials. CALF-20, nonetheless, stands out when it comes to each efficiency degree and flexibility underneath a wide range of environmental situations. The subsequent step is to find out sequestration processes in addition to an in depth financial evaluation to grasp the scalability and business viability of CALF-20.

Need to tweet about this text? Use hashtags #development #sustainability #infrastructure