If laptop chips make the trendy world go round, then Nvidia and TSMC are flywheels maintaining it spinning. It’s price paying consideration when the previous says they’ve made a chipmaking breakthrough, and the latter confirms they’re about to place it into follow.

At Nvidia’s GTC developer convention this week, CEO Jensen Huang stated Nvidia has developed software program to make a chipmaking step, referred to as inverse lithography, over 40 occasions quicker. A course of that often takes weeks can now be accomplished in a single day, and as an alternative of requiring some 40,000 CPU servers and 35 megawatts of energy, it ought to solely want 500 Nvidia DGX H100 GPU-based methods and 5 megawatts.

“With cuLitho, TSMC can scale back prototype cycle time, improve throughput and scale back the carbon footprint of their manufacturing, and put together for 2nm and past,” he stated.

Nvidia partnered with among the greatest names within the trade on the work. TSMC, the biggest chip foundry on the planet, plans to qualify the strategy in manufacturing this summer season. In the meantime, chip designer, Synopsis, and tools maker, ASML, stated in a press launch they may combine cuLitho into their chip design and lithography software program.

What Is Inverse Lithography?

To manufacture a contemporary laptop chip, makers shine ultraviolet mild via intricate “stencils” to etch billions of patterns—like wires and transistors—onto easy silicon wafers at near-atomic resolutions. This step, referred to as photolithography, is how each new chip design, from Nvidia to Apple to Intel, is manifested bodily in silicon.

The machines that make it occur, constructed by ASML, price a whole bunch of tens of millions of {dollars} and may produce near-flawless works of nanoscale artwork on chips. The top product, an instance of which is buzzing away close to your fingertips as you learn this, might be probably the most complicated commodity in historical past. (TSMC churns out a quintillion transistors each six months—for Apple alone.)

To make extra highly effective chips, with ever-more, ever-smaller transistors, engineers have needed to get inventive.

Keep in mind that stencil talked about above? It’s the weirdest stencil you’ve ever seen. At present’s transistors are smaller than the wavelength of sunshine used to etch them. Chipmakers have to make use of some extraordinarily intelligent methods to design stencils—or technically, photomasks—that may bend mild into interference patterns whose options are smaller than the sunshine’s wavelength and completely match the chip’s design.

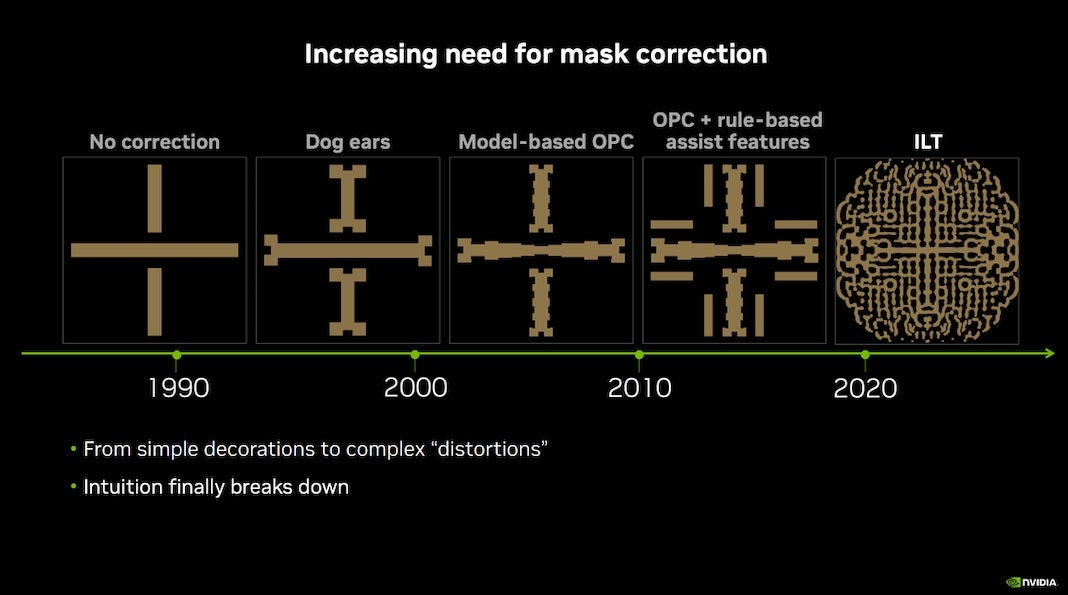

Whereas photomasks as soon as had a extra one-to-one form—a rectangle projected a rectangle—they’ve essentially change into increasingly sophisticated through the years. Probably the most superior masks nowadays are extra like mandalas than easy polygons.

To design these superior photomask patterns, engineers reverse the method.

They begin with the design they need, then stuff it via a depraved mess of equations describing the physics concerned to design an acceptable sample. This step known as inverse lithography, and because the hole between mild wavelength and have measurement has elevated, it’s change into more and more essential to the entire course of. However because the complexity of photomasks will increase, so too does the computing energy, time, and value required to design them.

“Computational lithography is the biggest computation workload in chip design and manufacturing, consuming tens of billions of CPU hours yearly,” Huang stated. “Huge information facilities run 24/7 to create reticles utilized in lithography methods.”

Within the broader class of computational lithography—the strategies used to design photomasks—inverse lithography is among the newer, extra superior approaches. Its benefits embrace better depth of area and backbone and will profit the complete chip, however due its heavy computational elevate, it’s at present solely used sparingly.

A Library in Parallel

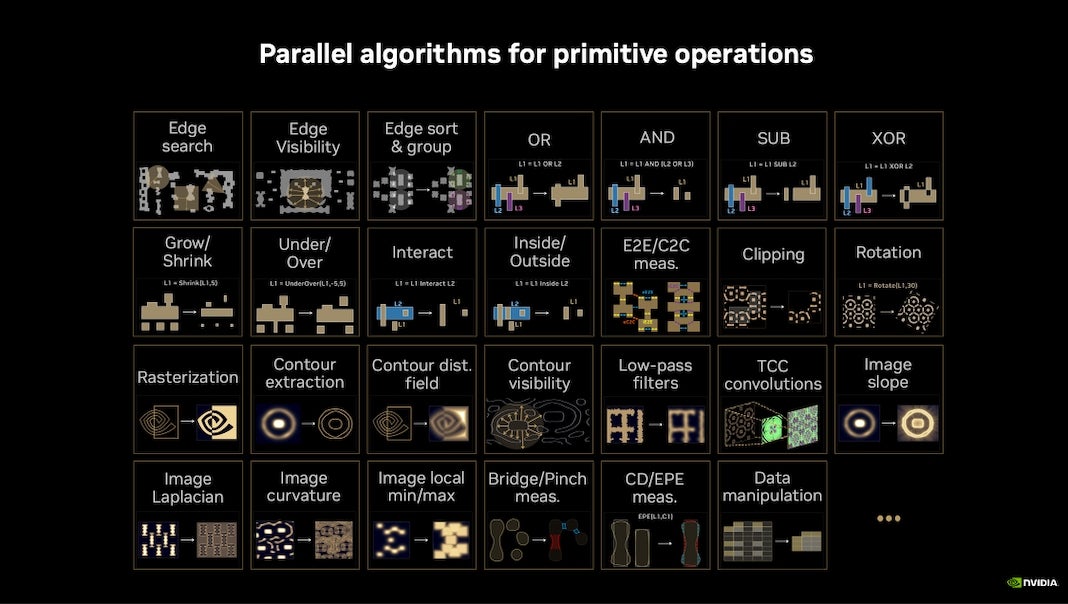

Nvidia goals to scale back that elevate by making the computation extra amenable to graphics processing models, or GPUs. These highly effective chips are used for duties with plenty of easy computations that may be accomplished in parallel, like video video games and machine studying. So it isn’t nearly operating present processes on GPUs, which solely yields a modest enchancment, however modifying these processes particularly for GPUs.

That’s what the brand new software program, cuLitho, is designed to do. The product, developed during the last 4 years, is a library of algorithms for the fundamental operations utilized in inverse lithography. By breaking inverse lithography down into these smaller, extra repetitive computations, the entire course of can now be cut up and parallelized on GPUs. And that, in keeping with Nvidia, considerably speeds all the pieces up.

“If [inverse lithography] was sped up 40x, would many extra individuals and firms use full-chip ILT on many extra layers? I’m positive of it,” stated Vivek Singh, VP of Nvidia’s Superior Expertise Group, in a chat at GTC.

With a speedier, much less computationally hungry course of, makers can extra quickly iterate on experimental designs, tweak present designs, make extra photomasks per day, and usually, increase using inverse lithography to extra of the chip, he stated.

This final element is vital. Wider use of inverse lithography ought to scale back print errors by sharpening the projected picture—which means chipmakers can churn out extra working chips per silicon wafer—and be exact sufficient to make options at 2 nanometers and past.

It seems making higher chips isn’t all concerning the {hardware}. Software program enhancements, like cuLitho or the elevated use of machine studying in design, can have a big effect too.

Picture Credit score: Nvidia