A nanostructured sensor, whose growth and checks concerned Skoltech researchers, has proven promise for enhancing development components fabricated from glass fiber-reinforced polymer composite supplies: plane wings, wind turbine blades, bridge spans, automotive our bodies, boat hulls, and so forth. It may be embedded right into a construction with out the necessity to remedy it in an autoclave.

Manufactured from carbon nanotubes, it generates warmth underneath electrical present; when embedded, it leaves the composite’s thickness unaffected, different traits unimpaired and doesn’t create undesirable pores. It will possibly function a sensor for structural well being monitoring or a heater for anti-icing or de-icing functions.

The latter is particularly essential for shipbuilding and small aviation, the place fiberglass buildings are plentiful, notably as regards this system of Arctic land growth. The examine was printed in Polymers.

“The outcomes of our analysis are outstanding for a number of causes,” one of many investigators of the examine, Main Analysis Scientist Sergey Abaimov of Skoltech, commented.

“For one factor, the composite is endowed with further performance: By making use of {an electrical} present to the carbon nanotube layer and monitoring the sign, it’s attainable to maintain monitor of the construction’s deterioration and avert catastrophe by anticipating breakage. Electrical energy may also be used for heating, for instance, to de-ice an plane wing or a wind turbine blade. Secondly, the heating can be utilized to fabricate this materials within the first place, ‘self-curing’ the polymer composite with out utilizing an autoclave, which is expensive and power-hungry.”

“Furthermore, and that is what the paper in Polymers is about, we’re additionally addressing the issue that plagues supplies with embedded microstructures basically: the hostile results of embedment on composite properties,” the lead writer of the examine, Skoltech’s Stepan Lomov, added.

“One would anticipate that when we embed carbon nanotubes—or something, actually—right into a composite, we have now to place up with elevated thickness and extra defects within the type of pores or distorted fiber orientation. However surprisingly, we find yourself with unchanged thickness, no added porosity, and the mechanical properties are improved, not compromised.”

Glass fiber-reinforced polymer composite supplies are utilized in plane, ships, bridges, vehicles, sports activities gear, and elsewhere. They’re produced by curing collectively many layers of glass fiber plies impregnated by epoxy resin. To provide a high-quality composite, your complete composite half—which is likely to be big, for instance, in plane engineering—is cured in a high-temperature, high-pressure chamber referred to as an autoclave.

Solely main corporations can afford an autoclave large enough to fabricate massive components with this know-how, and the electrical energy prices and environmental impression are additionally a priority, as a result of a lot energy is consumed to warmth up your complete quantity of the chamber each time, whatever the precise measurement and form of the composite half being cured.

“If you happen to embed carbon nanotubes between the adjoining layers of the composite, nevertheless, you’ll be able to apply an electrical present and really effectively ship warmth into the fabric with out losing power on heating your complete quantity of the autoclave. This might preserve one thing like 99% of the facility,” Abaimov stated.

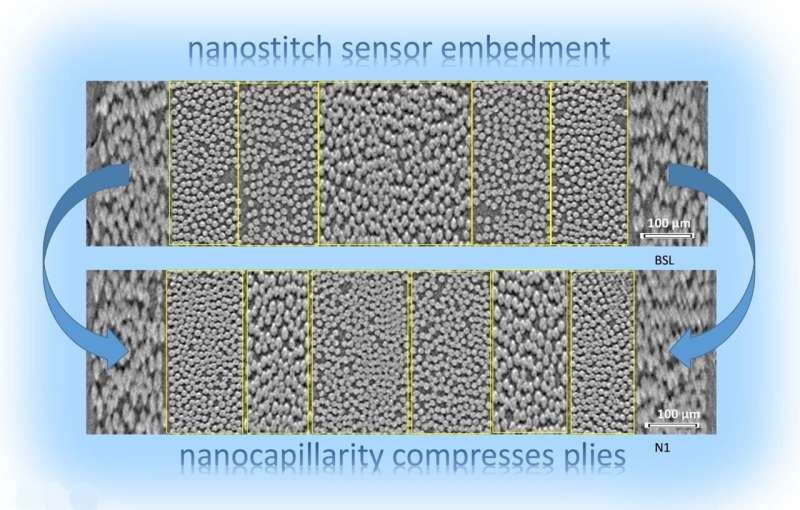

To match supplies’ traits, the staff manufactured the polymer composite each with out the embedded carbon nanotube construction and with it. Measurements revealed neither improve in thickness, nor undesirable pore formation, nor fiber misalignment.

The researchers defined this by way of the nanotubes’ extraordinarily excessive nanocapillarity, a property that causes them to “suck out” the pores from the epoxy resin, which might in any other case adversely have an effect on the composite’s traits, producing stress that causes the glass fiber layers to stay firmly collectively.

The examine reported on this story belongs to a subject of analysis that the authors themselves discuss with as “multifunctional fusion for life-cycle enhancement of supplies through nanoengineering of superior composite buildings.”

In different phrases, the proposed nanostructure enhances the properties of the fabric and endows it with a number of performance—on this case, structural well being monitoring and de-icing—in addition to enjoying an lively function at numerous levels of product’s life cycle, as early as its manufacture, when the conductive carbon nanotube layer allows out-of-autoclave curing of the composite.

Along with Skoltech Ph.D. scholar Alexei Shiverskii, Sergey Abaimov created a novel reactor for manufacturing nanocomposite buildings on the Institute. “The paper we printed this time is merely step one on the way in which to implementing the big selection of functionalities that we declare to exist,” Abaimov defined. “Subsequent, we have to get all the way down to work and obtain outcomes for all claimed functionalities, which must be of curiosity outdoors the lab, within the industries involved.”

Extra data:

Stepan V. Lomov et al, Affect of the Nanostitch Sensor Embedment on the Fibrous Microstructure of Glass Fiber Prepreg Laminates, Polymers (2022). DOI: 10.3390/polym14214644

Offered by

Skolkovo Institute of Science and Expertise

Quotation:

Nanostructure strengthens, de-ices, and screens plane wings, wind turbine blades, and bridges (2022, December 22)

retrieved 2 January 2023

from https://phys.org/information/2022-12-nanostructure-de-ices-aircraft-wings-turbine.html

This doc is topic to copyright. Aside from any honest dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for data functions solely.