In a multi-year venture, researchers at Chalmers College of Expertise in Sweden have developed plasmonic plastic—a kind of composite materials with distinctive optical properties that may be 3D-printed. This analysis has now resulted in 3D-printed optical hydrogen sensors that might play an essential function within the transition to inexperienced power and business.

Curiosity in plasmonic steel nanoparticles and their many various purposes has grown quickly, creating throughout a broad spectrum over the previous twenty years. What makes these particles so particular is their potential to work together strongly with gentle. This makes them helpful for a variety of purposes: as optical parts for medical sensors and coverings, in photocatalysis to manage chemical processes, and in varied sorts of fuel sensors.

Plasmonic plastic

For six years, Chalmers researchers Christoph Langhammer, Christian Müller, Kasper Moth-Poulsen, Paul Erhart and Anders Hellman and their analysis groups collaborated in a analysis venture on plasmonic plastic. On the time the venture started, plasmonic steel nanoparticles have been getting used totally on flat surfaces and required manufacturing in superior cleanroom laboratories.

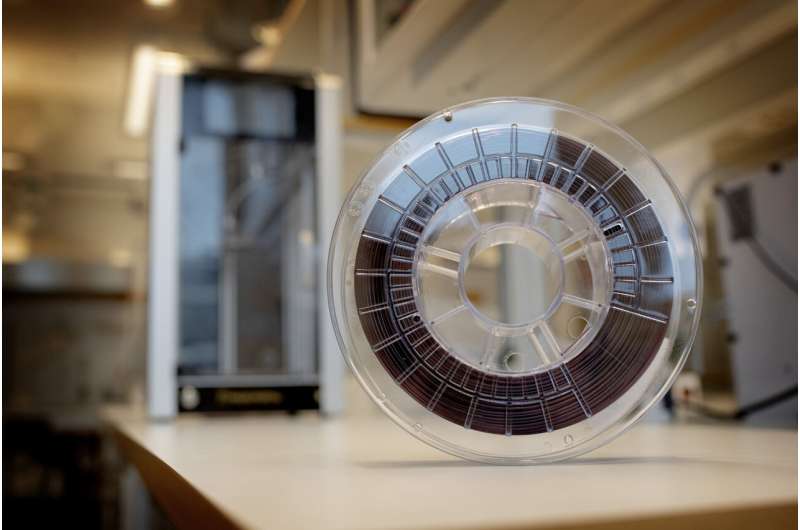

The researchers’ place to begin was to ask: what if we may produce massive volumes of plasmonic steel nanoparticles in a sustainable approach that might make it attainable to fabricate three-dimensional plasmonic objects? That is the place the plastic got here into the image. The properties of plastic supplies imply that they are often formed into nearly any kind, are cost-effective, have upscaling potential, and could be 3D-printed.

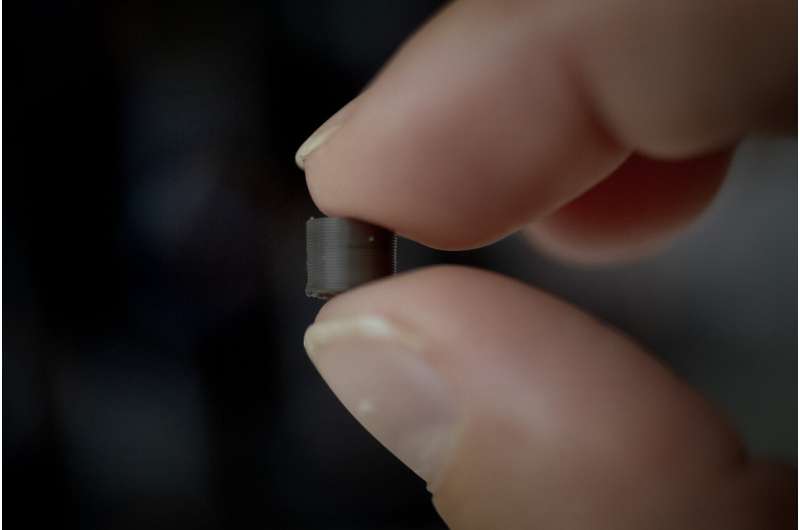

And it labored. The venture resulted within the improvement of recent supplies consisting of a mixture (or composite) of a polymer and colloidal, plasmonically lively, steel nanoparticles. With these supplies, you may 3D-print objects of something from a fraction of a gram as much as a number of kilograms in weight. Among the most essential analysis outcomes from your complete venture have now been summarized in an article in Accounts of Chemical Analysis.

3D-printed hydrogen sensors

Plasmonic sensors that may detect hydrogen are the goal software for this kind of plastic composite materials that the researchers selected to give attention to of their venture. In doing so, they’ve pioneered a completely new method within the discipline of optical sensors based mostly on plasmons, particularly with the ability to 3D-print these sensors.

“Several types of sensors are wanted to hurry up improvement in drugs, or the usage of hydrogen in its place carbon-free gasoline. The interaction between the polymer and nanoparticles is the important thing issue when these sensors are fabricated from plasmonic plastic.”

“In sensor purposes, this kind of plastic not solely permits additive manufacturing (3D printing), in addition to scalability within the materials manufacturing course of, however has the extra essential perform of filtering out all molecules besides the smallest ones—in our software, these are the hydrogen molecules we wish to detect. This prevents the sensor from deactivating over time,” says Christoph Langhammer, professor on the Division of Physics, who led the venture.

“The sensor is designed in order that the steel nanoparticles change colour after they are available contact with hydrogen, as a result of they take in the fuel like a sponge. The colour shift in flip alerts you instantly if the degrees get too excessive, which is crucial if you end up coping with hydrogen fuel. At too excessive ranges, it turns into flammable when combined with air,” says Christoph Langhammer.

Many purposes attainable

Whereas a discount in the usage of plastics is fascinating basically, there are quite a few superior engineering purposes which can be solely attainable because of the distinctive properties of plastics. Plasmonic plastics could now make it attainable to take advantage of the versatile toolbox of polymer know-how for designing novel fuel sensors, or purposes in well being and wearable applied sciences as different examples. It could even encourage artists and trend designers on account of its interesting and tunable colours.

“We now have proven that the manufacturing of the fabric could be scaled up, that it’s based mostly on environment-friendly and resource-efficient synthesis strategies for creating the nanoparticles, and is straightforward to implement. Throughout the venture, we selected to use the plasmonic plastic to hydrogen sensors, however in actuality solely our creativeness is the restrict for what it may be used for,” says Christoph Langhammer.

How plasmonic plastic works

- Plasmonic plastic consists of a polymer, equivalent to amorphous Teflon or PMMA (plexiglass), and colloidal nanoparticles of a steel which can be homogenously distributed contained in the polymer. On the nanoscale, the steel particles purchase helpful properties equivalent to the flexibility to work together strongly with gentle. The impact of that is known as plasmons. The nanoparticles can then change colour if there’s a change of their environment, or if they modify themselves, for instance by way of a chemical response, or by absorbing hydrogen.

- By dispersing the nanoparticles within the polymer, they’re protected against the environment as a result of bigger molecules will not be as able to shifting by way of the polymer as hydrogen molecules, that are extraordinarily small. The polymer acts as molecular filter. Which means a plasmonic plastic hydrogen sensor can be utilized in additional demanding environments, and can age much less. The polymer additionally makes it attainable to simply create three-dimensional objects of vastly totally different sizes which have these fascinating plasmonic properties.

- This distinctive interplay between the polymer, nanoparticles and lightweight can be utilized to realize personalized results, doubtlessly in a variety of merchandise. Several types of polymers and metals contribute totally different properties to the composite materials, which could be tailor-made to the actual software.

Extra info:

Iwan Darmadi et al, Bulk-Processed Plasmonic Plastic Nanocomposite Supplies for Optical Hydrogen Detection, Accounts of Chemical Analysis (2023). DOI: 10.1021/acs.accounts.3c00182

Supplied by

Chalmers College of Expertise

Quotation:

3D-printed plasmonic plastic permits large-scale optical sensor manufacturing (2023, September 28)

retrieved 29 September 2023

from https://phys.org/information/2023-09-3d-printed-plasmonic-plastic-enables-large-scale.html

This doc is topic to copyright. Aside from any honest dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is offered for info functions solely.