Oct 24, 2023

(

Nanowerk Information) It’s estimated that over 80% of engineering failures are as a result of materials fatigue, so the battle in opposition to metallic fatigue failures continues, as it is a key parameter for light-weight constructions for all mechanical methods, reminiscent of plane, vehicle and energy-production methods.

Just lately, joint analysis by Metropolis College of Hong Kong (CityU) and Shanghai Jiao Tong College achieved a breakthrough by creating an aluminium alloy with unprecedented fatigue resistance utilizing superior 3D printing methods. The brand new fatigue-resistance technique may be utilized in different 3D-printed alloys to assist develop light-weight elements with elevated load effectivity for numerous industries.

Key Takeaways

The fatigue resistance of this 3D-printed alloy is greater than double that of present 3D-printed aluminium alloys and even surpasses that of high-strength conventional aluminium alloys.

The brand new alloy was created utilizing Laser Powder Mattress Fusion, using AlSi10Mg powders adorned with TiB2 nanoparticles. The distinctive construction prevents localized injury accumulation and inhibits fatigue crack initiation.

The alloy has already been utilized in prototypes for giant, thin-walled constructions reminiscent of plane engine fan blades, demonstrating its potential for light-weight designs throughout numerous industries.

The breakthrough not solely advances the applying of 3D-printed supplies but in addition provides an answer to combating materials fatigue, thereby enhancing the sturdiness and effectivity of mechanical methods.

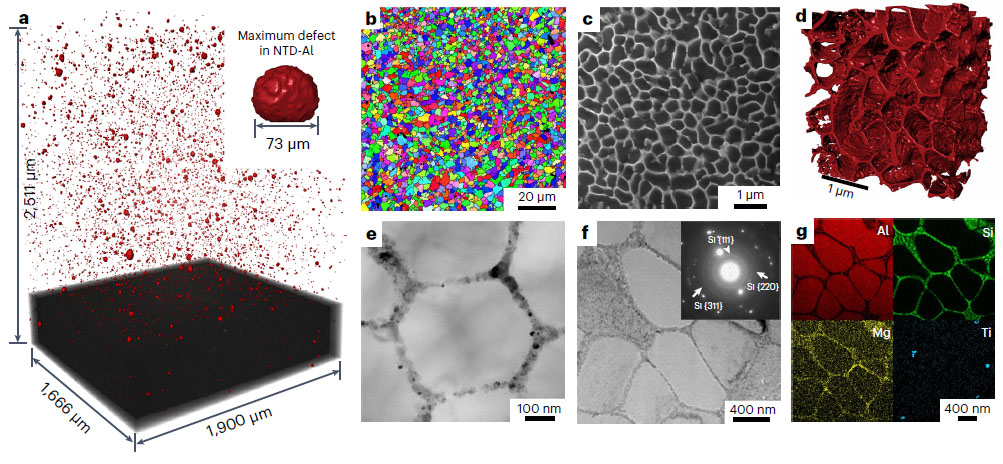

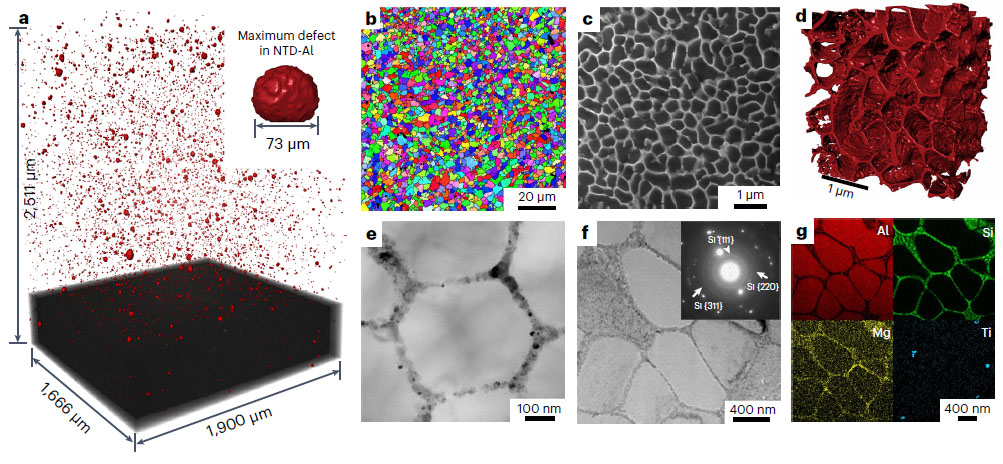

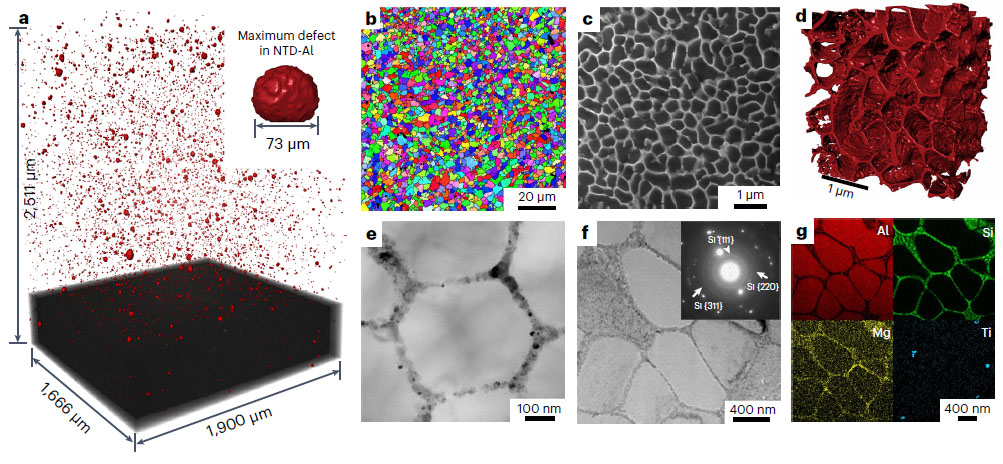

Microstructure of the AM NTD-Al alloy. (A) µ-CT evaluation exhibiting the spatial and measurement distribution of printing defects; the most important defect was 73 µm, solely about 1/3 of the dimensions of defects in AM AlSi

10Mg alloy with out TiB

2 ornament. (B) Grain morphology of the printed pattern. (C) A community of solidification mobile construction with a median diameter of ~ 500 nm. (D) Steady 3D Si mobile construction revealed by BSE/FIB tomography. (E) Mobile construction consisting of nanosised Si phases revealed by TEM. (© Nature Supplies)

The Analysis

“The fatigue phenomenon in metals was found about two centuries in the past. Since then, fatigue failure has grow to be some of the necessary points within the lifespan and reliability of all dynamic mechanical methods, reminiscent of these in plane, vehicles and nuclear energy vegetation,” mentioned Professor Lu Jian, Dean of Faculty of Engineering, and Director of the Hong Kong Department of the Nationwide Valuable Metals Materials Engineering Analysis Heart (NPMM) in CityU, who co-led the analysis.

Standard metals exhibit fatigue power usually decrease than half their tensile power. “Low fatigue power is prompted primarily by multi-scale defects within the supplies, which proceed to develop and evolve with cyclic loading, forming macroscopic cracks and increasing ultimately into bigger cracks that destroy all the materials construction,” he defined. “This difficult phenomenon additionally occurs in alloys produced by additive manufacturing, also called 3D-printing, limiting additional purposes of 3D-printed supplies.”

To beat the difficulty of low fatigue resistance in 3D-printed alloys and customarily in all metallic supplies, a joint-research workforce of CityU and Shanghai Jiao Tong College used Laser Powder Mattress Fusion (LPBF) – some of the extensively used metallic additive manufacturing methods – to efficiently fabricate a novel aluminium alloy from AlSi

10Mg powders adorned with TiB

2 nanoparticles. The fatigue resistance of this 3D-printed nano-TiB

2-decorated AlSi

10Mg (NTD-Al alloy) is greater than double that of different 3D-printed aluminium alloys and surpassed these of high-strength wrought AI alloys.

The findings had been printed in

Nature Supplies(

“Attaining ultrahigh fatigue resistance in AlSi10Mg alloy by additive manufacturing”). And so they had been featured within the “Analysis Highlights” of

Science Attaining ultrahigh fatigue resistance in AlSi

10Mg alloy by additive manufacturing, which described it as a normal technique for different alloys to spice up fatigue resistance.

The workforce used micro-computed tomography to research this 3D-printed NTD-Al alloy and located all through the pattern a typical steady 3D-dual-phase mobile nanostructure, which consisted of a community of solidification mobile construction with a median diameter of about 500 nanometers. The 3D-dual-phase mobile nanostructure acts as a powerful volumetric nanocage to forestall localised broken accumulation, inhibiting fatigue crack initiation.

“The three-dimensional community of nano eutectic silicon (Si) generated by additive manufacturing contained in the alloy as a result of fast solidification may block the motion of dislocations, thus suppressing fatigue crack initiation,” mentioned Professor Lu. “With managed defects by way of course of optimisation, the fatigue restrict of the majority NTD-Al alloy is superior to that of all present Al alloys.”

In a collection of fatigue assessments, the analysis workforce discovered that the printed bulk NTD-Al alloy achieved fatigue resistance of 260 MPa, which was greater than double that of different additive manufacturing Al alloys. The excessive fatigue power restrict of the majority NTD-Al alloy surpassed that of all different Al alloys, together with standard high-strength wrought Al alloys with restricted metallurgical defects.

The NTD-Al alloy has already been utilized to manufacture prototypes of huge thin-walled constructions, together with the fan blades of plane engines designed for top fatigue power, and efficiently handed the qualifying fatigue take a look at.

“These findings point out the potential applicability of our alloy for the light-weight constructions vital in industries the place fatigue properties are the important thing design criterion. Our alloy can assist cut back weight by growing the load effectivity of transferring elements,” added Professor Lu.

Mixed with some great benefits of 3D printing, the newest discovery will increase light-weight design and cut back carbon emissions in fashionable industries. And the identical technique may be additionally used for different supplies to assist remedy the fatigue failure problem in metallic additive manufacturing,” concluded Professor Lu Jian.

The examine was a collaboration between Professor Wang Haowei’s and Professor Lu’s groups. The co-first authors of the paper are Dr Dan Chengyi, Assistant Professor Cui Yuchi, Affiliate Professor Wu Yi and Professor Chen Zhe from Shanghai Jiao Tong College. The co-corresponding authors are Professor Lu from CityU and Professor Chen. Additionally collaborating within the examine was Dr Liu Hui, former postdoc within the Division of Mechanical Engineering at CityU.

Microstructure of the AM NTD-Al alloy. (A) µ-CT evaluation exhibiting the spatial and measurement distribution of printing defects; the most important defect was 73 µm, solely about 1/3 of the dimensions of defects in AM AlSi10Mg alloy with out TiB2 ornament. (B) Grain morphology of the printed pattern. (C) A community of solidification mobile construction with a median diameter of ~ 500 nm. (D) Steady 3D Si mobile construction revealed by BSE/FIB tomography. (E) Mobile construction consisting of nanosised Si phases revealed by TEM. (© Nature Supplies)

Microstructure of the AM NTD-Al alloy. (A) µ-CT evaluation exhibiting the spatial and measurement distribution of printing defects; the most important defect was 73 µm, solely about 1/3 of the dimensions of defects in AM AlSi10Mg alloy with out TiB2 ornament. (B) Grain morphology of the printed pattern. (C) A community of solidification mobile construction with a median diameter of ~ 500 nm. (D) Steady 3D Si mobile construction revealed by BSE/FIB tomography. (E) Mobile construction consisting of nanosised Si phases revealed by TEM. (© Nature Supplies)

Microstructure of the AM NTD-Al alloy. (A) µ-CT evaluation exhibiting the spatial and measurement distribution of printing defects; the most important defect was 73 µm, solely about 1/3 of the dimensions of defects in AM AlSi10Mg alloy with out TiB2 ornament. (B) Grain morphology of the printed pattern. (C) A community of solidification mobile construction with a median diameter of ~ 500 nm. (D) Steady 3D Si mobile construction revealed by BSE/FIB tomography. (E) Mobile construction consisting of nanosised Si phases revealed by TEM. (© Nature Supplies)

Microstructure of the AM NTD-Al alloy. (A) µ-CT evaluation exhibiting the spatial and measurement distribution of printing defects; the most important defect was 73 µm, solely about 1/3 of the dimensions of defects in AM AlSi10Mg alloy with out TiB2 ornament. (B) Grain morphology of the printed pattern. (C) A community of solidification mobile construction with a median diameter of ~ 500 nm. (D) Steady 3D Si mobile construction revealed by BSE/FIB tomography. (E) Mobile construction consisting of nanosised Si phases revealed by TEM. (© Nature Supplies)