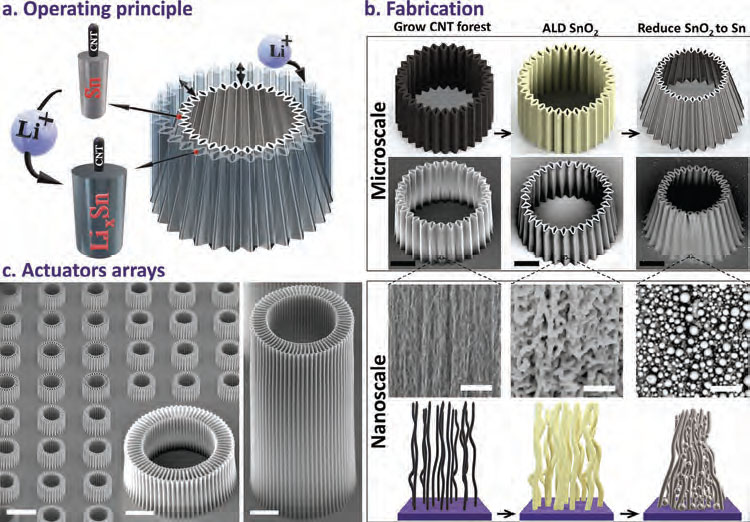

Actuation mechanism and wafer-scale fabrication of 3D microstructures: a) Schematic of the electrochemical alloying response of Li–Sn and ensuing volumetric growth at nano/microscale. This non-volatile and reversible course of is managed by easy electrical present. b) Schematic of the totally different steps in fabrication technique of the CNT/Sn 3D microstructures at nano and micro scales (prime rows) with their corresponding SEM pictures (decrease rows). c) The SEM picture of the 3D microstructures arrays fabricated by CVD development of vertically aligned CNT forests with complicated geometries from 2D patterns. (c, inset) CNT forests with various heights starting from microns to millimeter with rising pace of ≈100 µm min−1. The SEM imaging is carried out at 45° tilt angle; scale bars: (b, prime row), 50 μm; (b, decrease row), 2 µm (c) 200 µm; (c, inset), 100 µm. (Reprinted with permission by Wiley-VCH)

Earlier shape-changing techniques typically relied on comfortable lively supplies like stimuli-responsive polymers or hydrogels. Nonetheless, leveraging the acute tensile energy of CNT scaffolds, the Cambridge group achieved expansions much like polymers with the upper stiffness of tin. This amplifies the ensuing actuation and opens new prospects in micro-electromechanical and optically adaptive techniques.

Their manufacturing technique additionally strikes past earlier specialised methods with low throughput. As an alternative, by integrating carbon nanotube development and atomic layer deposition, hundreds of responsive pixels could be produced in parallel.

The hybrid materials works by lithiating tin via a easy electrical present, inflicting it to swell as much as 250% in a spontaneous alloying response. This reshaping is achieved via an electrochemical course of the place lithium ions intercalate into the tin, essentially altering its quantity. The bodily growth of tin, pushed by this electrochemical course of, exerts drive on the carbon nanotubes, enabling their managed actuation.

The swelling pushes on stiff, vertically aligned CNTs, programmed into intricate cone or lattice shapes. The electronically managed and constantly variable transformation is maintained after eradicating the stimulus. Biking is achieved by reversing the method via de-lithiation. These capabilities come from elementary battery rules however at smaller scales for micrometer-range actuation.

By means of simulation-guided design, the researchers created responsive, electrochromic buildings optimized for giant, lateral form change quite than extreme peak shifts. Modulating geometric parameters and sidewall patterns, an over 95% growth was achieved. The ensuing strokes reached as much as ten occasions these of earlier experiences primarily based on softer lively gels. Stability was demonstrated throughout 70+ cycles and electrochromic switching may camouflage the reversible actions.

After detailing the numerous advances and potential functions of those responsive nanoarchitectures, it is also vital to acknowledge the challenges that stay. The paper notes the air-sensitivity of the CNT-Sn system, which presents a hurdle for long-term sturdiness in real-world environments. This side emphasizes the necessity for additional analysis in growing extra strong supplies and sealing strategies to boost the longevity and sensible usability of those buildings.

Moreover, whereas the scalability of the manufacturing course of is a significant breakthrough, the combination of those supplies into current technological platforms could require extra diversifications. Addressing these challenges might be essential for absolutely realizing the transformative potential of this expertise in functions corresponding to interactive surfaces and microscale units.

Sooner or later, huge arrays of those dynamic pixels may cowl interactive surfaces for warmth regulation, gentle manipulation, or lively camouflage. Microscale robotic cilia are one other risk, as are miniature pumps or valves for labs-on-a-chip.

This breakthrough provides thrilling prospects in miniaturizing micro-electromechanical techniques (MEMS), probably revolutionizing small-scale system expertise.

The simplicity {of electrical} management and compatibility with electronics integration ought to propel functions. New sealing strategies will doubtless be wanted for longevity in real-world settings. Nonetheless, by bringing collectively scalable manufacturing and battery-inspired actuation, this advance offers a place to begin to remodel fields counting on responsive motions.

In essence, this analysis marks a big stride within the evolution of responsive supplies, bridging the hole between theoretical promise and sensible software.

Actuation mechanism and wafer-scale fabrication of 3D microstructures: a) Schematic of the electrochemical alloying response of Li–Sn and ensuing volumetric growth at nano/microscale. This non-volatile and reversible course of is managed by easy electrical present. b) Schematic of the totally different steps in fabrication technique of the CNT/Sn 3D microstructures at nano and micro scales (prime rows) with their corresponding SEM pictures (decrease rows). c) The SEM picture of the 3D microstructures arrays fabricated by CVD development of vertically aligned CNT forests with complicated geometries from 2D patterns. (c, inset) CNT forests with various heights starting from microns to millimeter with rising pace of ≈100 µm min−1. The SEM imaging is carried out at 45° tilt angle; scale bars: (b, prime row), 50 μm; (b, decrease row), 2 µm (c) 200 µm; (c, inset), 100 µm. (Reprinted with permission by Wiley-VCH)

Earlier shape-changing techniques typically relied on comfortable lively supplies like stimuli-responsive polymers or hydrogels. Nonetheless, leveraging the acute tensile energy of CNT scaffolds, the Cambridge group achieved expansions much like polymers with the upper stiffness of tin. This amplifies the ensuing actuation and opens new prospects in micro-electromechanical and optically adaptive techniques.

Their manufacturing technique additionally strikes past earlier specialised methods with low throughput. As an alternative, by integrating carbon nanotube development and atomic layer deposition, hundreds of responsive pixels could be produced in parallel.

The hybrid materials works by lithiating tin via a easy electrical present, inflicting it to swell as much as 250% in a spontaneous alloying response. This reshaping is achieved via an electrochemical course of the place lithium ions intercalate into the tin, essentially altering its quantity. The bodily growth of tin, pushed by this electrochemical course of, exerts drive on the carbon nanotubes, enabling their managed actuation.

The swelling pushes on stiff, vertically aligned CNTs, programmed into intricate cone or lattice shapes. The electronically managed and constantly variable transformation is maintained after eradicating the stimulus. Biking is achieved by reversing the method via de-lithiation. These capabilities come from elementary battery rules however at smaller scales for micrometer-range actuation.

By means of simulation-guided design, the researchers created responsive, electrochromic buildings optimized for giant, lateral form change quite than extreme peak shifts. Modulating geometric parameters and sidewall patterns, an over 95% growth was achieved. The ensuing strokes reached as much as ten occasions these of earlier experiences primarily based on softer lively gels. Stability was demonstrated throughout 70+ cycles and electrochromic switching may camouflage the reversible actions.

After detailing the numerous advances and potential functions of those responsive nanoarchitectures, it is also vital to acknowledge the challenges that stay. The paper notes the air-sensitivity of the CNT-Sn system, which presents a hurdle for long-term sturdiness in real-world environments. This side emphasizes the necessity for additional analysis in growing extra strong supplies and sealing strategies to boost the longevity and sensible usability of those buildings.

Moreover, whereas the scalability of the manufacturing course of is a significant breakthrough, the combination of those supplies into current technological platforms could require extra diversifications. Addressing these challenges might be essential for absolutely realizing the transformative potential of this expertise in functions corresponding to interactive surfaces and microscale units.

Sooner or later, huge arrays of those dynamic pixels may cowl interactive surfaces for warmth regulation, gentle manipulation, or lively camouflage. Microscale robotic cilia are one other risk, as are miniature pumps or valves for labs-on-a-chip.

This breakthrough provides thrilling prospects in miniaturizing micro-electromechanical techniques (MEMS), probably revolutionizing small-scale system expertise.

The simplicity {of electrical} management and compatibility with electronics integration ought to propel functions. New sealing strategies will doubtless be wanted for longevity in real-world settings. Nonetheless, by bringing collectively scalable manufacturing and battery-inspired actuation, this advance offers a place to begin to remodel fields counting on responsive motions.

In essence, this analysis marks a big stride within the evolution of responsive supplies, bridging the hole between theoretical promise and sensible software.

By

Michael

Berger

– Michael is creator of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Expertise,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Abilities and Instruments Making Expertise Invisible

Copyright ©

Nanowerk LLC

Grow to be a Highlight visitor creator! Be a part of our massive and rising group of visitor contributors. Have you ever simply revealed a scientific paper or produce other thrilling developments to share with the nanotechnology neighborhood? Right here is easy methods to publish on nanowerk.com.